Though many drivers (and even some technicians) may not realize how far it has come, the market for tire pressure monitoring system (TPMS) sensors and tools has evolved.

A decade ago, many drivers and technicians did not understand the significant safety and fuel economy benefits of TPMS. In 10 years, more drivers have become aware of the benefits of TPMS. Programmable replacement TPMS sensors have lowered prices for consumers, and improved coverage has made it possible for shops to stock an inventory of TPMS sensors.

But the most significant leap forward has been the evolution of the dedicated TPMS tool. Ten years ago, all a TPMS tool could do was ping sensors and read the transmitted data as part of a relearn procedure. It was not until TPMS tools were able to communicate with the vehicle through the OBDII port that new diagnostic and service opportunities opened up for shops.

The latest TPMS tools are part diagnostic scan tool and part low-power radio wave diagnostic tools. The new machines can diagnose sensors on the vehicle as well as program new sensors. They can even be used to diagnose keyless entry fobs to see if they are transmitting – a critical function in today’s automotive and light truck platforms.

New dedicated TPMS tools can confirm the operation of the sensors and system without having to go for a test drive. Specific test procedures are engineered by the tool’s manufacturer that can force a relearn procedure, so when the car leaves your shop, you will know the TPMS light is out and will stay out.

The most important thing to remember is to trust and learn what your TPMS tool can do. The latest tools can perform procedures that can make replacing sensors and diagnostics easier and some even have training built into the device.

Sensor Replacement Strategies

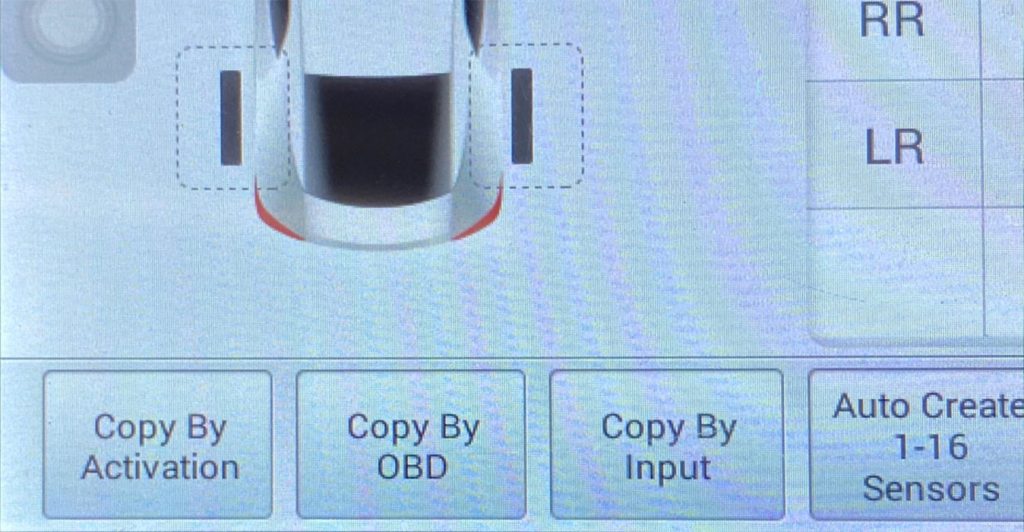

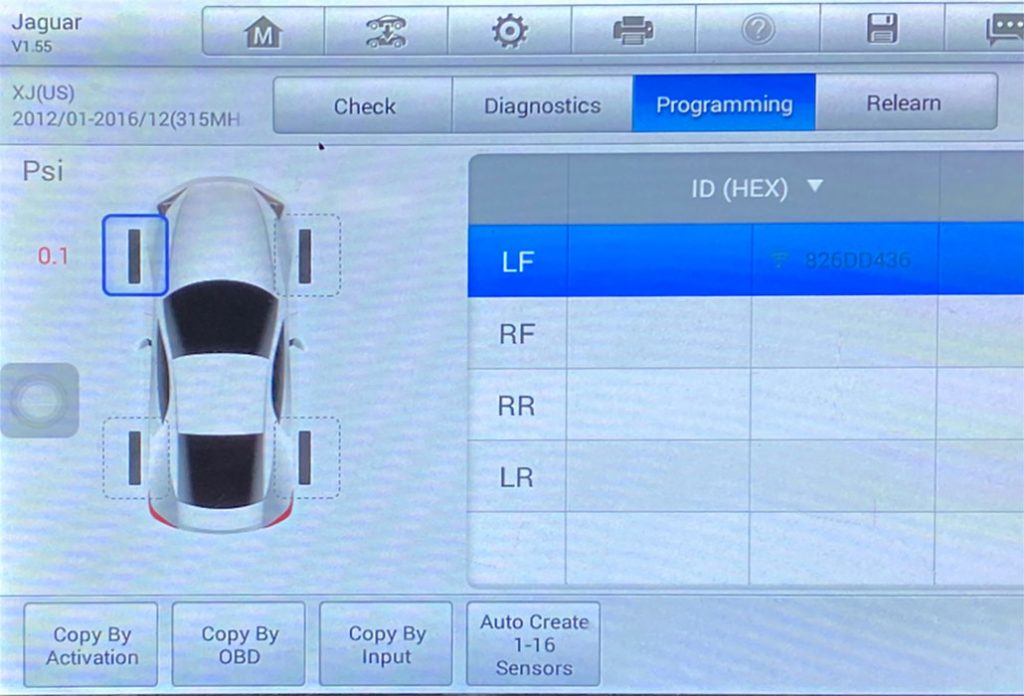

Using new TPMS tools, you can have several options to replace and reprogram a sensor.

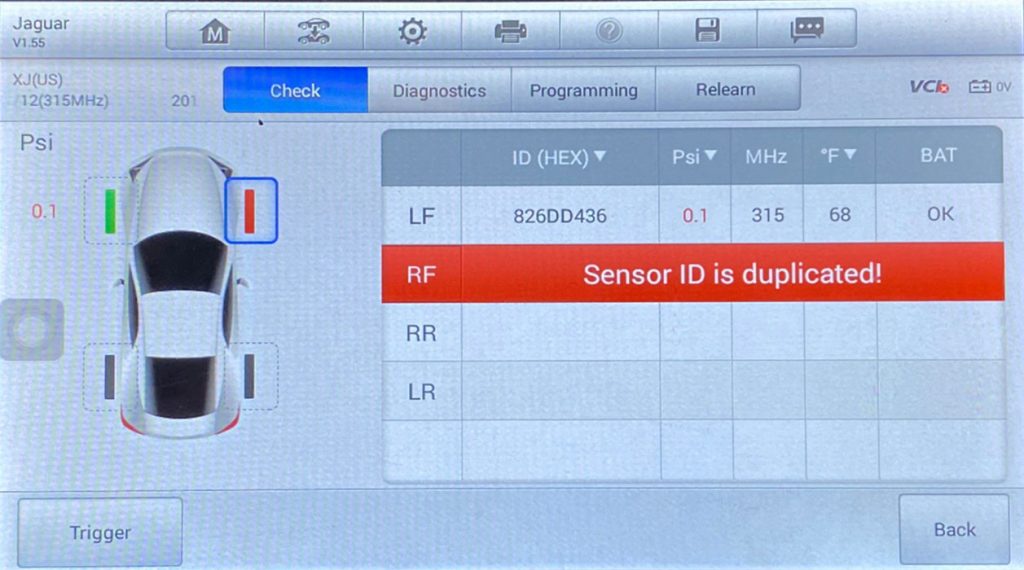

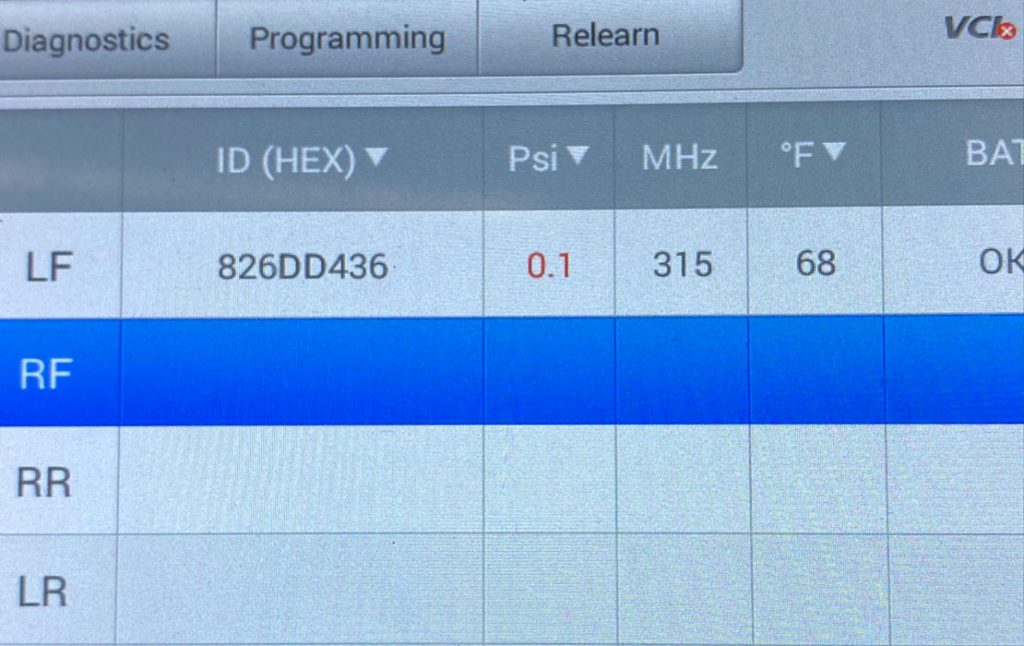

If the old sensor is still transmitting, you can pull the ID using your TPMS tool and create a new sensor.

If the sensor is no longer transmitting due to damage or the failure of its internal battery, the ID will still be in the memory of the module that operates the TPMS system. Some TMPS tools can communicate through the OBDII port and find the ID number for the dead sensor. This ID can then be programmed into a replacement sensor.

Printed on the side of the original TPMS sensor is an ID number. With some TPMS tools, the ID number can be read off the sensor and programmed into a replacement sensor.

In some cases, it might be easier to generate a new sensor ID. Some TPMS tools can create a random ID that can be programmed into a TPMS sensor and the TPMS module.