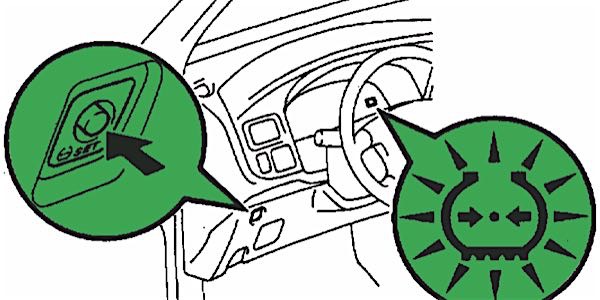

Toyota TPMS might seem like the easiest system to service because most models have a reset button under the dash, but trusting in this button to cure all of your TPMS issues might get you in trouble.

This button puts the system into learning or initialization mode. The TPMS listens for three minutes or until all of the sensor IDs have been received by the module. The sensor transmits this data once a minute when the vehicle is stationary. If the module does not receive the data from a sensor, the light will continue to flash (eventually staying on) and codes will be set in the tire pressure ECU. The system may even get stuck in a loop during the initialization process while looking for missing sensors.

Unlike other tire pressure monitoring systems that require a “poke” to the sensor with an activation tool, there is no way to confirm the sensor is transmitting. After three minutes, it is either pass or fail for all four sensors. To further diagnose the system, you will need a dedicated TPMS tool that can communicate through the OBD II port.

Basic Operation

If there is a TPMS problem with a Toyota, check the TPMS warning light in the instrument cluster or “combination meter” before proceeding with additional diagnostics. Any time the vehicle is started, the TPMS light should come on for three seconds and go out as part of a self-diagnostic procedure.

If the light does not come on, there could be an issue with the module or serial data communications. This needs to be addressed before checking other components. You should connect a scan tool to see if the TPMS module data PIDs can be accessed. Make sure you check for codes in the instrument cluster, and pay extra attention to the communication codes. The tire pressure ECU communicates with other modules using CAN protocols.

If the light stays on after the three seconds, it is an indication that one of the tires is above or below the inflation threshold. Inflate all four tires to the correct pressure and the light should go out.

If the light flashes in 0.5-second intervals, it means there is a failure in the tire pressure ECU, antenna and/or sensors. It can indicate that a sensor ID is missing or has not been received. After one minute, the TPMS light should be steady.

When the TPMS system is in the initialization mode, the light will flash for one second and turn off for one second. This will stop once all of the sensor IDs are received or after three minutes. If the initialization procedure is not successful, code C2177 for “initialization incomplete” will be set in the module.

If there is a problem with one or more of the sensors communicating with the TPMS module during the reset procedure, it could go into a “looping” mode where it locks out the use of the SET button, and the TPMS light will flash and set a code for “lost communication with ECU.”

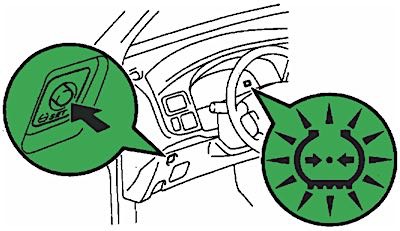

The system is now stuck in this looping mode, and no matter how many times you press the tire pressure reset button or cycle the ignition, the TPMS light will continue to flash. The only way to stop the looping is to connect pins 13 and 4 in the OBD II port with a jumper wire.

The better solution is to use a tool that plugs into the connector and connects the pins internally. This tool prevents potential damage to the fragile OBD II connector and helps you avoid the trouble of crawling into the foot well to make the connection.

Diagnostics and Codes

If you dive into the Toyota service information regarding its TPMS, you will notice that if there is a problem with the sensors or module, the standard operating procedure is to connect the factory scan tool to the OBD II port to observe the sensor IDs and data. There are no other shortcuts.

Codes are stored by the tire pressure ECU. These codes are like misfire codes with the last digit indicating the sensor ID with the fault. They also operate like misfire codes because it may take multiple incidents to cause a hard code to be set. These codes cover inflation, missing data and temperature malfunctions. Other codes cover communication with the other components.

The Toyota Way

As stated earlier, when you perform a TPMS relearn on most vehicles, you “poke” the sensors with a radio frequency and force it to transmit. Toyotas do not operate this way — they wait and listen for the IDs. While waiting for the sensor to transmit, the unpredictable can happen. Radio interference from another vehicle or tool in the shop could prevent the signal from reaching the antenna. Something as simple as a sensor being positioned behind a brake caliper can interfere with the signal.

If you are using a dedicated TPMS scan tool for Toyota relearns, it can poke the sensors so the tool can capture the IDs. Then, those IDs can be injected into the tire pressure ECM. This approach has several advantages. First, a weak or dead sensor can be detected before the relearn procedure. It can also audit the tire pressure. Second, there is no chance for the sensor ID to miss the antenna because you are using a wired connection. Third, you need a tool that connects through the OBD II port to replace a sensor that has a different ID number. You can’t use the reset button.