Vehicle Application: 2004 Outback 3.0L

Vehicle Application: 2004 Outback 3.0L

Customer Concern and Initial Diagnostics: The A/C compressor intermittently shuts off. The technician called the Identifix Hotline with the following concerns and report. The customer drove the vehicle about 1/4 mile before it shut off the last time. If the engine was left running, the A/C stayed off. If the engine was shut off and then restarted, the A/C would start working again, losing ground for the A/C relay. The tech went through the self-diagnosis of the automatic A/C system and it gets a 20 (no malfunction detected). The ambient sensor, the in-vehicle sensor and the intake sensor all read normal temperatures. The scan tool does not show A/C request or A/C relay information. The scan tool shows engine temperature at 190° F. The A/C compressor rpm sensor was replaced, but that did not help.

Potential Causes: A/C compressor revolution sensor wiring

Tests/Procedures:

1. Backprobe and check the A/C request circuit voltage on the black/white wire in terminal A2 (terminal 2 of connector A, which is connector B134) at the engine control module (ECM). Look for battery voltage to be present from the auto A/C control module for A/C request to be on.

2. If the A/C request voltage goes to 0 volts when the A/C compressor shuts off, perform voltage tests at the auto A/C control module.

3. If the A/C request voltage stays at battery voltage when the A/C compressor shuts off, backprobe and check the ground for the A/C relay on the blue/orange wire in terminal D27 (terminal 27 of connector D, which is connector B137). If the A/C relay ground goes to battery voltage (no ground), then ground the blue/orange wire at D27 and verify the A/C relay and the compressor clutch turns back on.

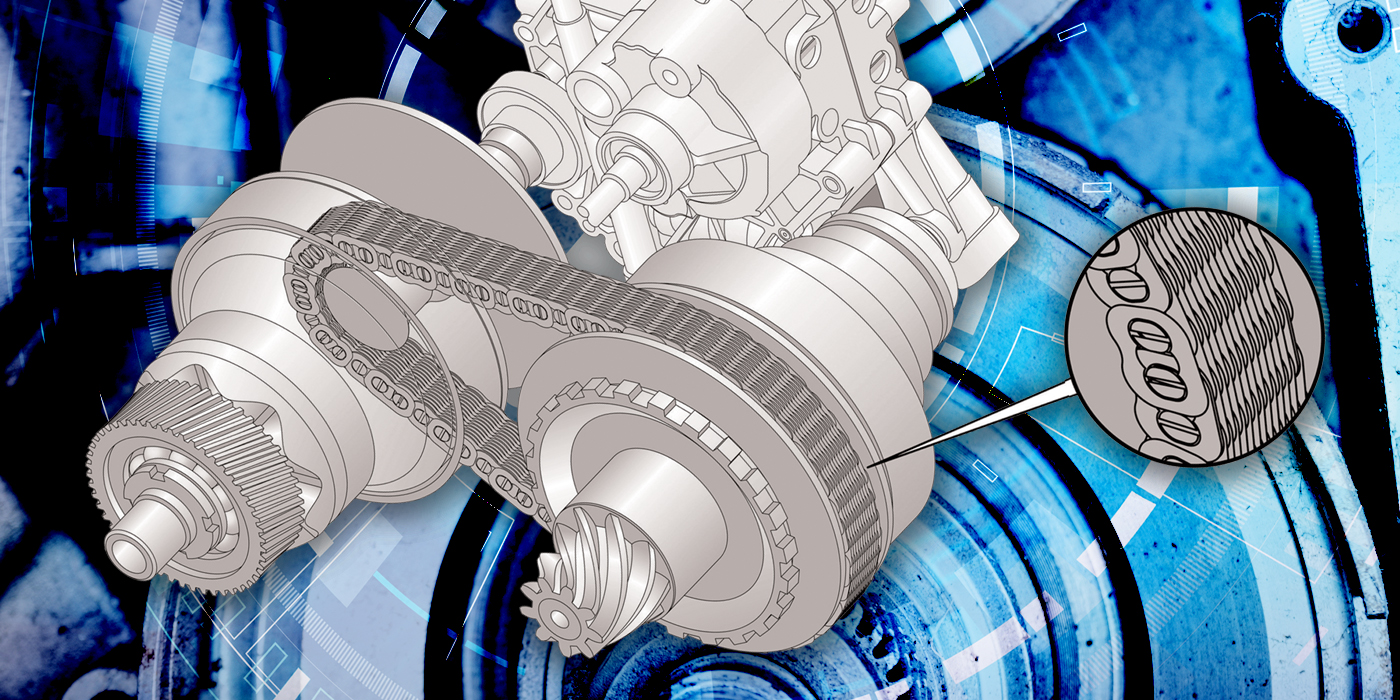

4. Scope the A/C compressor rpm sensor on the white wire at terminal A13 (terminal 13 of connector A) at the ECM and look for a clean, consistent AC sine wave signal with the engine running and the A/C compressor clutch on.

5. Make sure the ground for the A/C compressor rpm sensor is good on the black wire.

6. Check ECM grounds as necessary.

Tool tip courtesy of Identifix.