The campaign aims to raise $65,000 through 1,000 donations of $65 each.

The Automotive Aftermarket Charitable Foundation (AACF) announced the launch of its 65th-anniversary fundraising initiative. Running through July 1, 2024, the campaign aims to raise $65,000 through 1,000 donations of $65 each. This impactful effort highlights the industry's commitment to taking care of its own, the AACF said.

From sudden illness and death to natural disasters, the foundation has provided assistance to industry professionals and their families during their darkest hours. As AACF celebrates its 65th year of service, it remains steadfast in its mission to provide financial support and resources to those in the automotive aftermarket industry in need, the organization said.

The brake system of a hybrid may have multiple components to perform regenerative braking and pedal simulation.

Regenerative braking takes the forward motion of the vehicle and turns it into electrical energy.

A second generation Toyota Prius is at least 12 years old and batteries may need to be replaced. Here’s what the codes mean.

The secret to diagnosing air ride problems is knowing what criteria the system uses to regulate the compressor/reservoir and having the right tool.

The release provides new coverage in 53 distinct product categories and 47 part numbers for 2023 and 2024 model-year vehicles.

Grew company from small machine shop to global leader in car lifts and garage equipment.

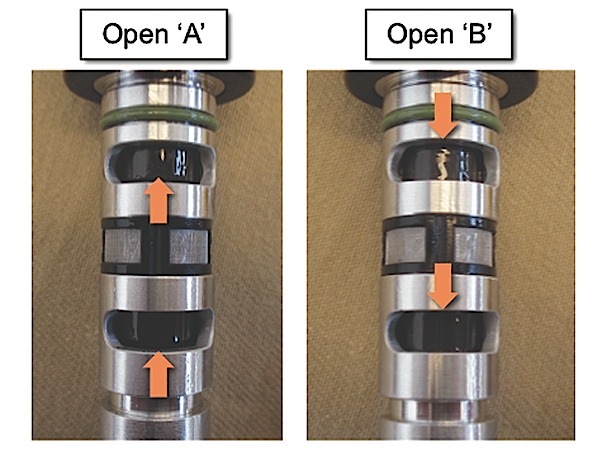

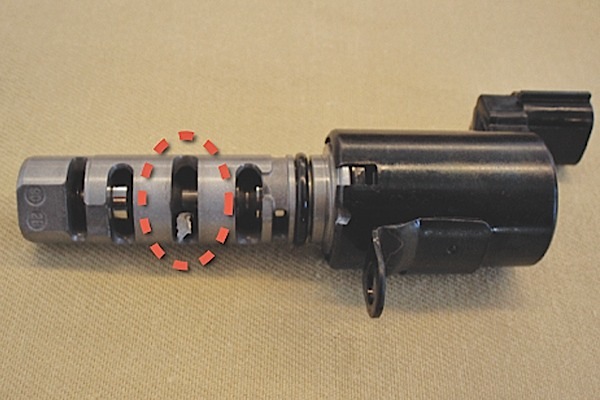

Work procedures vary slightly for certain platforms. This article outlines the different procedures to follow.

You can get a good idea of what to expect by adding the official ASE practice tests to their study plans.