Needs Come First When Choosing Aftermarket Or OE

In the debate between OEM and aftermarket suspension parts, it’s essential to understand the differing needs of manufacturers, shops, technicians, and consumers.

VIDEO: Understanding Control Arms

Control arm replacements must match the original. This video is sponsored by ZF Aftermarket.

Prevent Premature Jeep JK Part Wear with Ball Joint Upgrades

Visit any online forum dedicated to the Jeep® Wrangler JK, and you’re likely to find threads focused on solutions for fixing a worn or damaged ball joint. That’s because ambitious off-roading, popular modifications, and the design of the original equipment part can all contribute to ball joint failure in the Jeep JK. Ball joints are

Mevotech Tech Tip: Installing Directional Ball Joints

Some ball joints must be installed in a specific orientation to function correctly. These ball joints are designed to allow for a large amount of ball stud swing in the cross-car or side-to-side direction as the suspension travels up and down.

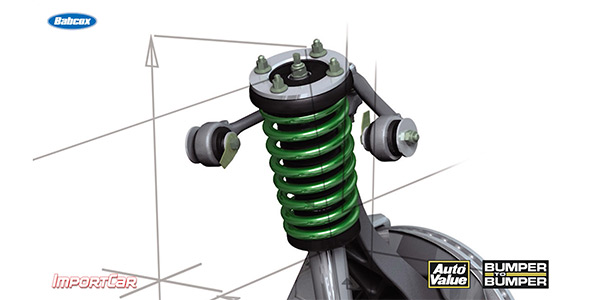

VIDEO: Ball Joint Installation Innovations

Andrew Markel discusses the installation process of chassis components, and how some changes in ball joint design are making the process easier. Sponsored by Auto Value and Bumper to Bumper.

VIDEO: Ball Joint Stud Specifications

Andrew Markel discusses the evolution of ball joints, and how their attachment to aluminum components has called for more stringent torque specifications. Sponsored by Auto Value and Bumper to Bumper.

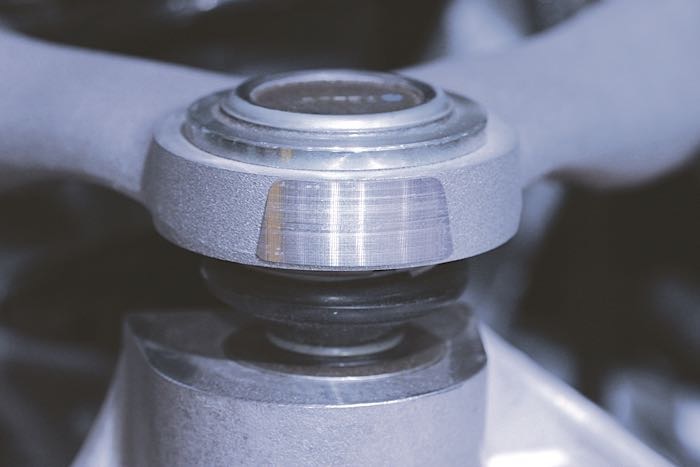

Ball Joint Friction And Wear

If you went to the doctor for a routine examination, and he pulled out some heavy-duty medical instruments right away, you might get a little scared that fixing your ailment might be worse than the ailment itself. The same is true for ball joints and tie rods.

Ball Joints: Greasable And Sealed

One of the most frequent questions from customers is in regards to the availability of “greasable” chassis parts. Sealed-for-life components are very common at the OEM level, but many technicians have a definite preference for aftermarket greasable components. This poses the question: If greasable suspension joints are so popular, why don’t many modern suspensions have grease fittings anymore?