I recently had a 2007 Subaru Forester with an elusive problem in the shop. It was equipped with the 2.5L SOHC Active Valve Lift System (AVLS) and the horizontal four-cylinder engine. While one of our techs and I were working through it, I was also teaching a Subaru driveability class for NAPA. This gave me the opportunity to talk about the diagnostic approach we used to narrow down this problem and to learn that many of my students were not really clear on how the engine worked. Many thought it had variable valve timing, even though it does not. Others were not aware of the ALVS that Subaru brought out in 2006. With that in mind, I’d like to share some insights into this very clever engine management strategy.

Active Valve Lift System SPECIFICS

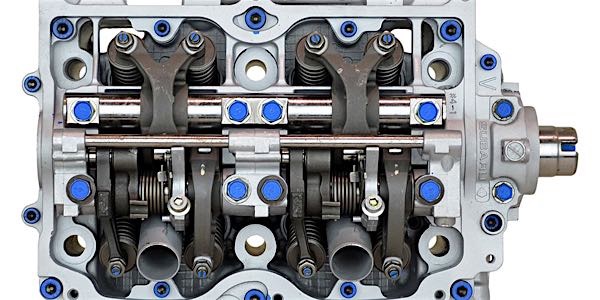

If you are familiar with Honda’s VTEC, you will already be several steps ahead in understanding Subaru’s AVLS. Each cylinder has four valves. It is a SOHC, so a single tandem rocker operates the two exhaust valves. It gets interesting when you look at the intake side. There are three 1.75:1 rocker arms per cylinder. The constant lobe has a lift of 10.8 mm. The low-lift lobe has a lift of around 5.7 mm and the high-lift cam is 11.12 mm. It should be noted that the duration and lobe centerlines of these three lobes are also different. The active part of this system occurs between the low-lift and high-lift rockers.

Swirl and Air/Fuel Ratio Averaging

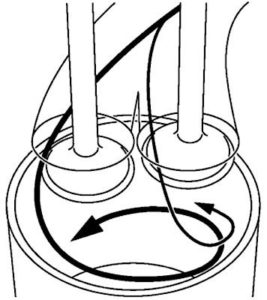

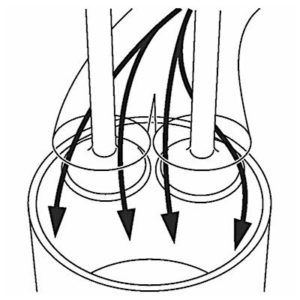

Subaru uses the dramatically different valve lift in Mode 1 — low lift with the constant lift to create swirl. As we have learned over the years, swirl is most effective at lower engine speeds. Mode 1 is most active at calculated loads under 59% at speeds under 50 mph. Once RPM is over about 2,800, it is far less likely to create a condition where it can activate — mainly when decelerating at any speed with very low loads. The “water swirling down the drain effect” that Subaru achieves by lifting one intake valve more than the other helps it to also create a better environment to run a lean air/fuel ratio.

With port injection, the swirl is arranged so that the area around the spark plug has a richer fuel mixture. We know that a richer mixture makes it easier for the spark plug because there is less electrical resistance across the gap in its presence. By concentrating the fuel in this area, the remainder of the cylinder has a higher air/fuel ratio that helps lower emissions and keep fuel from attaching itself to the cylinder walls. The average still delivers Lambda, and this engine does not exhibit the light throttle lean surge that many other “eco mode” approaches do.

Hot Rod Cam on Standby

The high-lift cam is stabilized when it’s not in use by a spring to keep it from rattling. As calculated load RPM, TPS or vehicle speed dictated by the PCM strategy are met, engine oil is directed to an oil control valve in each head to drive a pin into the high-lift rocker. This engages it and causes the low-lift rocker to lose contact with its cam journal. This effectively alters the overall cam duration, lift and the engine’s torque curve. Since we are not using this mode at low speed, the focus is more on horsepower.

What Can Go Wrong?

Subaru has issued a TSB for updated spark plug wires to correct problems with carbon tracking. The ignition coil towers have also had problems with carbon tracking and poor ground connections. This is a wasted-spark system with a three-wire coil that utilizes one power wire and one PCM grounded wire for each pair of cylinders (1 and 2, and 3 and 4 are the pairings). It is very common for a pair to set misfire codes if one of them is acting up. There are software updates for the single-cell, wide-band O2 sensor heater to improve cold weather emissions and converter life expectancy.

One of the less-documented problems comes when cylinder head or engine work is performed. There are several different crank gear/cam sprocket packages used on this engine. Mixing these up or using the manual or automatic trans cam sprockets in the wrong application can result in a no-start condition. If you are servicing the heads on these engines, keep the crank and cam gears unless there is a very good reason to replace them, and then be sure you match them up.

There are two things you can encourage your customers to do to preserve the heads. One is to get the valve adjustment checked on time to prevent the valves from becoming burned. The second critical engine saver is servicing the cooling system. Subaru had the head gaskets pretty much figured out by this time, but coolant neglect can still take out the open deck head gaskets on this engine.