On most Asian imports and domestic vehicles, the brake pad wear sensor was just a piece of bent sheet metal that would make contact with the rotor when the brake pad was worn past minimum specifications. It works only if the “squealer” can stay on the brake pad and if the driver knows what the squealing means. But with today’s well-insulated vehicles and air conditioning, the driver does not notice until grinding and pedal feedback are present.

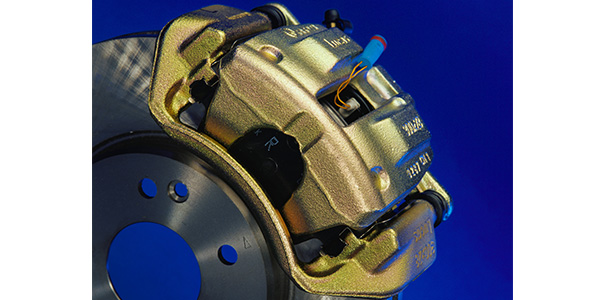

Most luxury European vehicle owners do not want to find out they need new brake pads because of obnoxious grinding. On most high-end German imports, there are brake pad wear sensors that alert the driver with a light and warning on the dash. These vehicles use a loop of wire embedded in the friction material. The loop is set in the last 3 mm to 5 mm of pad material or the sensor is set in plastic and attached to the backing plate. When the pads wear down, the loop is broken. This triggers a change in resistance that causes the warning.

Brake pad wear sensors have been around for more than 40 years. But, in the past decade, they have evolved so that brake wear can be estimated. This has allowed drivers to pick the right time to have their brake pads replaced.

Old School

Most older brake pad wear systems had a sensor at each corner of the vehicle on the inboard pad. These systems can vary in the number of wheels that have sensors and where the placement is on the pads. Since the 1970s, they have been just a loop of wire with a small amount of current running through them.

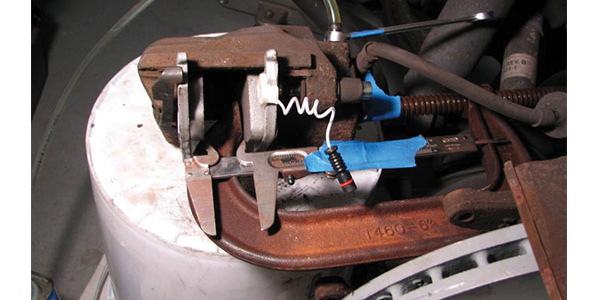

On these older systems, the sensor itself had a known resistance value. When the resistance exceeded 2,000 ohms, a rectifier circuit in the instrument cluster sensed it as an open circuit and turned on the light. The most common failure for these types of circuits was physical damage and corrosion at the connector. This is why it is recommended that the sensor be replaced even if it has not come into contact with the brake rotor.

New School

Modern brake pad wear sensors can do more than just warn the driver of a worn brake pad. These new wear sensors work with the rest of the brake system and can estimate the mileage until the brake pads wear out.

New wear sensors work just like old sensors. But, some new sensors have two resistor circuits in parallel at two depths. The first resistor circuit is set at a higher position in the sensor, and the second resistor circuit is at a lower position.

When the first resistive circuit is broken, the resistance in the sensor will increase due to the resistors having a parallel structure. When the second wire is broken, the circuit is now open. This might trigger a more aggressive warning message for the driver.

The first resistive circuit will not typically set a warning light. The information is used by the brake system to estimate the pad life remaining, in addition to using other information. Called two-stage wear sensors, these are monitored by the ABS module and instrument cluster module on some vehicles.

The system wear sensors use information such as wheel speed, mileage, brake pressure, brake disc temperature and brake operating time to determine the life remaining in the pads. This is displayed in the information center or with a warning lamp that may go from yellow to red. Some systems may show the life left on the pads during startup. But, the brake pad wear estimate performed by the computer may not match the real world.

It is also critical to check that the vehicle has a reset procedure when the brake pads are replaced. This procedure can differ depending on the manufacturer. Some BMWs can be reset using the iDrive information center. And, some Mercedes-Benz and Audi models may require a scan tool. On some vehicles, you need to make sure the date is set correctly for the system to make an accurate prediction.

The old trick of splicing the wires together to bypass the warning light will not work with two-stage sensors. The module passes voltage through the circuit and uses the amount of voltage drop to confirm that the sensor is working. If the system notices that no voltage is dropping across the circuit, it will set a malfunction warning light.

Parking Brake Wear Measurements

On some European vehicles like Mercedes-Benz, rear pad life is measured using the electronic parking brake module. The system engages the rear brakes with the stepper motor in the caliper or the motor that actuates the cables. The system will count the number of motor rotations needed to engage the rear brake pads. Some systems do this measurement with the key off.

Service Precautions

It is always a good idea to replace removable wear sensors. Over time, the heat from the brakes can damage the wiring and the clip that holds in the sensor. These sensors are very inexpensive, when compared to a comeback. Many premium pads will include them as part of the brake pad set and are available from many aftermarket suppliers.

Also, check the connector on the vehicle. Corrosion inside the connector can cause changes in the resistance of the sensor. Make sure seals are secure inside the connector; some technicians use di-electric grease.

If you look at brake system wiring diagrams for some luxury vehicles, you may see that there is a connection to a telematics module with the CAN Bus. This connection is there so the estimated life of the brake pads can be shared with the OEM and potentially a local dealer so the driver can set up an appointment to have the brakes serviced.

But, this level of connectivity has recently drawn criticism because it leaves the brake system open for cyberattack. However, many owners fail to renew their subscriptions, so the system may no longer be connected to the dealer.