Customers have a lot of questions when it comes to TPMS. Here are some solid answers to help you help them at the front counter.

Q: I put air in all my tires, but the light is still on. What’s going on?

A: First, double check that you inflated all your tires to the appropriate PSI listed on your vehicle placard inside your driver’s side door. This includes any full-size spare tires. If a tire keeps losing air pressure, or the light comes back on a day or so after you fill your tires, you will need to seek immediate repair, as there is most likely a leak in one or more tires.

Other reasons for the TPMS light to come on and stay on are:

• A dead or failing sensor battery.

• A TPMS module not receiving signals from one or more sensors because of an antenna or wiring fault.

• A TPMS module is not functioning properly or has failed because of a voltage supply, wiring or internal electronics fault.

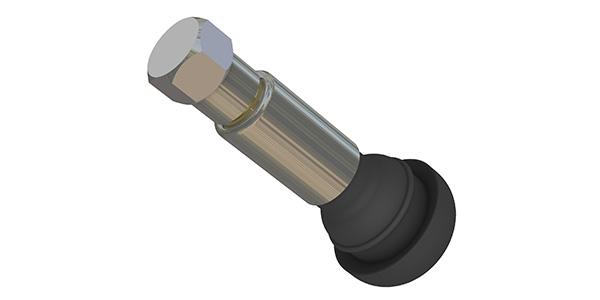

• Corroded valve stems could also be causing issues with the system, or the tire’s ability to hold air.

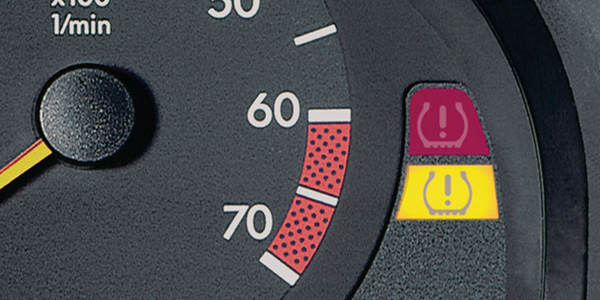

Q: My TPMS light is flashing. What does that mean?

A: TPMS is an advance technology and technology fails. If your TPMS indicator light is flashing, your TPMS is malfunctioning. TPMS devices have batteries that can die or a sensor could have gone bad or needs reprogrammed.

Q: What if I don’t have the service kits replaced?

A: Every time a tire is removed from a car, the TPMS should get a new service kit. Not replacing the kits could cause big problems with tire pressure and vehicle TPMS if not properly serviced.

There are several reasons you should never reuse parts or sensor kits when servicing TPMS:

• Valve stems are subjected to heat from both the brakes and road and can degrade over time.

• If a nut is reused, the anodized aluminum surface (which protects against galvanic corrosion and material deterioration) could be scratched away. This could cause corrosion between the sensor, wheel and stem, making the nut impossible to torque to the correct specifications or remove due to corrosion on the threads.

• Reusing seals and grommets can also cause problems. On the sensor, the two grommets help seal the nut to the wheel. As soon as the nut is torqued the grommets conform to the shape of the wheel. Once this happens, the previous shaping can’t be fixed and reusing these pieces may cause a slow leak

Q: Why can’t you just put in normal valve stems?

A: According to Federal law, a shop may not “make inoperative” a TPMS system. If you take your vehicle in for service with a working TPMS, your car must leave the shop with a working TPMS. For more information, check out the National Highway Traffic Safety Administration’s “make inoperative” provision of the Motor Vehicle Safety Act.

Q: When do the sensors measure the tire pressure?

A: The timing of when TPMS sensors measure the inflation pressure of a tire varies based on vehicle make and model. Sensors tend to cycle every couple of minutes when the vehicle is in operation. TPMS sensors send out information via radio waves and if the sensor constantly sent out signals, the battery would die faster.

Q: The TPMS light goes out before I get to the gas station. Why?

A: There are several reasons a TPMS light could turn off before reaching a service station to have air added. Driving the vehicle could have warmed up the tires, increasing the inflation pressure past the 25% low threshold, turning off the light.

Some TPMS relearns require the vehicle to be driven for a short distance before shutting off the light.

However, even if the light turns off, check the pressure of your tires to make sure they meet the PSI listed on your vehicle placard inside your driver’s side door. A digital tire pressure gauge is most accurate measurement.

Q: Can’t you just change the batteries? Why do I need new sensors?

A: Batteries are built into TPMS sensors. The average battery life of a sensor is 10 years, though this varies based on how much the vehicle is driven. The more the vehicle is driven, the more often the TPMS sensors generate their signals, and the faster they use up their remaining battery life.

Q: Why are you recommending four new sensors when only one is causing the light to come on?

A: Sensor life spans vary but, on average, they all have a 10-year/150,000-mile battery life.

Once one sensor dies, the rest are likely to be close behind. It is a good practice to replace all four sensor batteries at the same time – this saves the customer the hassle of returning for additional service.

Q: What happens if I drive with my TPMS light on?

A: While the light itself won’t cause any issues, running your tires underinflated can cause a multitude of problems.

TPMS is basically a warning system. Attached to each of your road wheels, this little device allows your vehicle to notify you if any tire’s air pressure is running low. A light on the dash indicates significantly low PSI, air pressure in pounds per square inch, when it is 25% below the recommended PSI for a vehicle.

Running your tires underinflated can compromise your tires’ performance. The contact patch would change, impacting rolling resistance, handling and stopping distance. This does not mean you should over-inflate your tires though – over-inflated tires can also lead to changes in contact patch, uneven wear and handling.

Under-inflated tires can also cost you at the pump. For every 1 psi drop in the average pressure of all tires, you lower gas mileage by about 0.2%, according to fueleconomy.gov. A loss of 3 psi is equivalent to $0.02/a gallon. While it’s only pennies per gallon, cost can add up quickly.