By declaring a customer’s brake pedal pulsation complaint is caused by warped rotors is like saying the earth is flat. Both are cases where the observation of the person is based on a tiny piece of evidence that is false in nature and application.

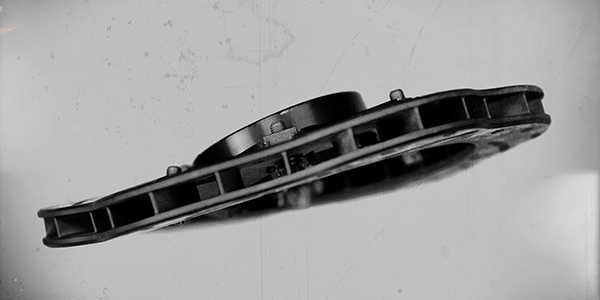

The technician must first understand what is making the pedal pulsate. Pulsation is generated by the interaction between the rotor, pads and caliper. As the driver produces hydraulic force, it pushes the caliper pistons out, which then pushes the brake pads into the rotor. If one area of the rotor is thicker than the other, the pads will have to follow the thickness of the rotors. This action moves the piston in the brake caliper.

When the piston moves, it moves the brake pedal that is connected to the driver’s foot. When the low spot is passing by the brake pads, the piston extends and the pedal drops. When the thickest part passes by the caliper, the piston is forced back into the caliper, the piston compresses into the housing, and the pedal goes up in height — the faster the stop, the more significant and more rapid the pulsation.

The allowable tolerance is known as parallelism or disc thickness variation, or DTV in the service information.

Runout is defined as the amount of lateral (side-to-side) movement of the rotor as it rotates 360 degrees. The specification is usually provided as “TIR” or “total indicated runout.” TIR is defined as the runout measured on the vehicle or installed runout. You could also call TIR the stacked runout of the hub/rotor/wheel assembly since they all add up to produce the rotor’s TIR.

The average allowable TIR specification for late-model vehicles is between 0.001 and 0.003 inch, which is the maximum allowed. Some manufacturers have specified 0.000 inch of runout.

Runout will NOT cause pedal pulsation on vehicles with floating or sliding calipers — the caliper housing is free to move and the runout is not excessive. But, excessive runout will cause DTV, which will then cause brake pedal pulsation.

Lateral runout will cause the rotor to contact the brake pads, knocking them back as the high spot of the runout contacts the pads. It also removes a little bit of the material from the rotor’s high spot. Eventually, enough material is removed. This causes DTV, the direct cause of brake pedal pulsation.

Solutions

The first solution to solve pulsation problems is to prevent them from happening in the first place. That’s why runout and DTV should be measured and documented with every brake job. This includes pad slaps, machining rotors and installing new rotors.

Second, pay particular attention to the mounting flange. Taking time to clean the mounting flange on the hub can remove corrosion and debris that can cause runout. Also pay attention to lug nut torque.

Third, take time to service the caliper, slides and hardware. If a caliper cannot float or retract the piston, it could result in increased wear that could lead to DTV and pulsation.

Fourth, using an on-the-car lathe can help to reduce runout. The main advantage of these lathes is that they can cut a rotor in its operating plane. This means that the rotor is machined to match the hub.