When replacing only one component in the power steering system, other components may retain exiting contamination that must be removed from the system. Failure to do so may potentially cause damage to the newly installed component. Contamination can cause a rack to leak or a pump to make noise as well as malfunction in terms of creating desired levels of pressure.

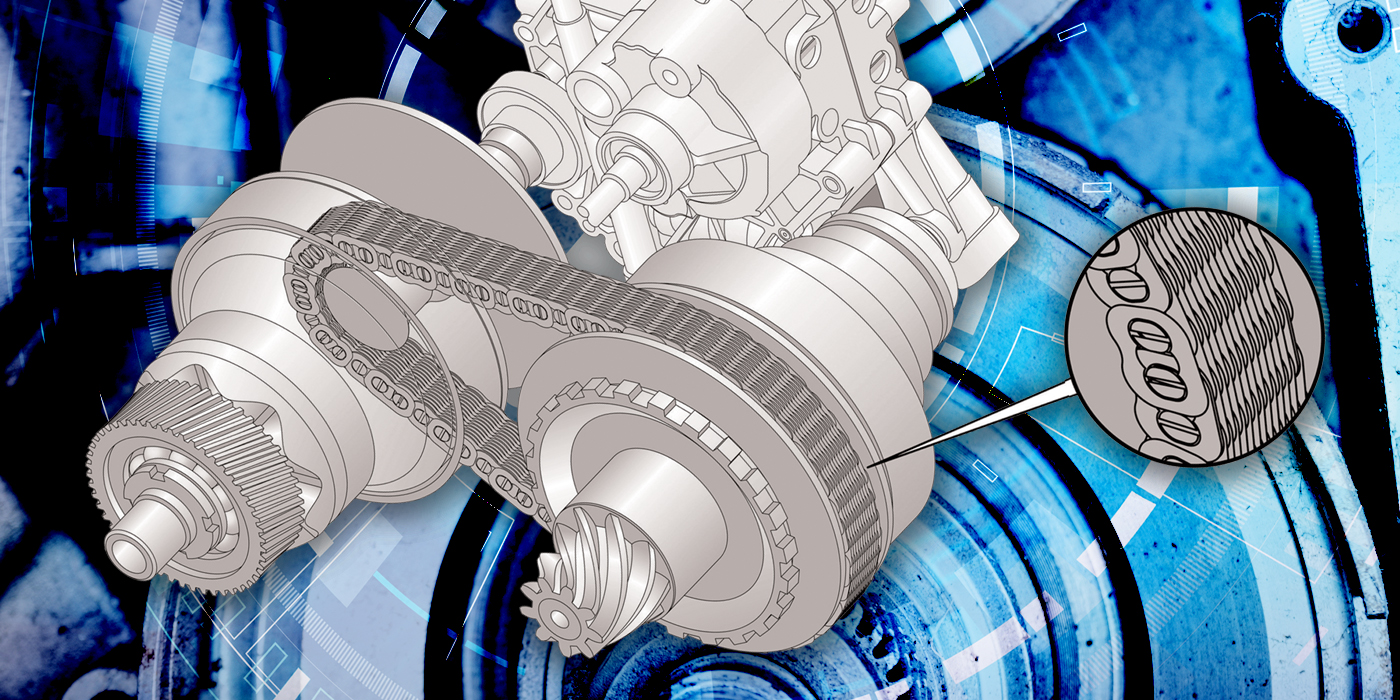

Examining the fluids from the power steering system can assist in diagnosing other component issues. Before replacing a steering rack or pump, remove a small sample of the fluid through the rack return hose and place in dark waste container. Let fluid sample settle before continuing with examination. Using a flashlight, shine light directly into the fluid sample. If the fluid sample contains any metal shaving contamination, this is a direct result of a failing power steering pump and the pump should be replaced at the same time a new rack is installed. If the fluid sample contains small fragments of rubber, this is an indication that the hoses are experiencing deterioration and should be replaced.

If the fluid has a dark appearance or strong burnt odor, these are also indicators that the pump has been run low on fluid and has potentially been damaged.

Replace The Hoses

Check all the power steering hoses. If you spot a leak, or if the hose feels stiff or spongy, replace all the hoses in the system. The hoses are all made from similar compounds. If one hose is rotted, it is a sure sign all hoses are probably rotted. Not only is a deteriorated hose unsafe, but it will retain residue which contaminates the new rack and/or pump and causes malfunctions.

Always Flush The System

- Disconnect the pressure hose from the rack and place into a waste container. Disconnect the return hose from the pump and place into a waste container. Plug the pump inlet connector port.

- Fill the pump reservoir with correct power steering fluid for your vehicle.

- While another person continues to fill the reservoir, turn over the engine in very short burst. Do not allow the pump to run without fluid as this will cause damage to the part. Repeat this cycle until the fluid coming from the pressure hose is clear and contamination free.

- Reconnect the pressure hose to the rack. Remove the inlet connector port plug and reconnect the return hose to the pump.

- Refill the reservoir with the appropriate recommended fluid. Do not recycle or reuse the old fluid used to flush the system.

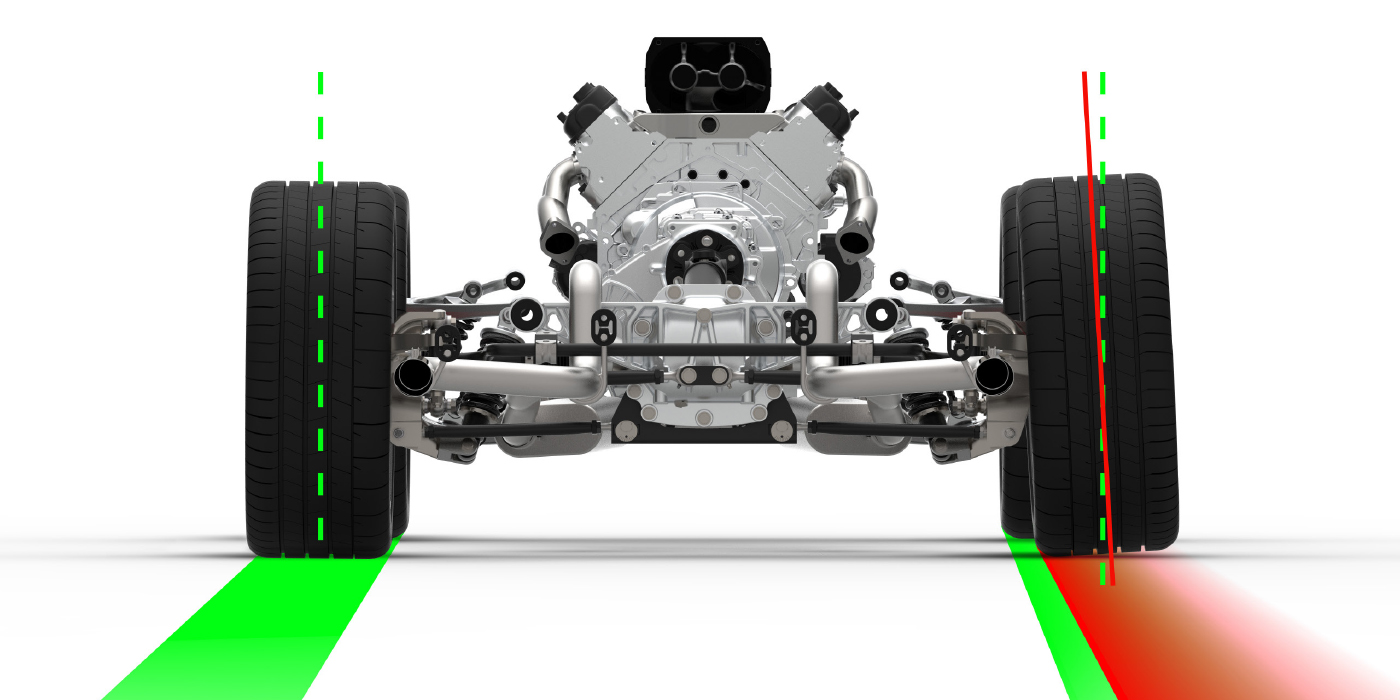

- While another person continues to fill the reservoir, crank the engine and cycle the steering wheel from left lock to right lock position several times with the wheels not in contact with the ground. Add additional fluid as needed While cycling the steering wheel. The system is self-bleeding and after continuous cycles, all air within the system should be removed. Inspect reservoir fluid for bubbles or noise coming from the system Continue to purge the system until all bubbles or noise are gone.

- Do not over fill reservoir. Replace reservoir cap once system has been properly filled.

Courtesy of AAE Steering System Specialist