The 959 was another first to use a tire pressure monitoring system (TPMS) because it was equipped with the world’s first self-supporting run-flat tires made by Bridgestone. This TPMS setup was again used on the 928 for model years 1990 to 1994.

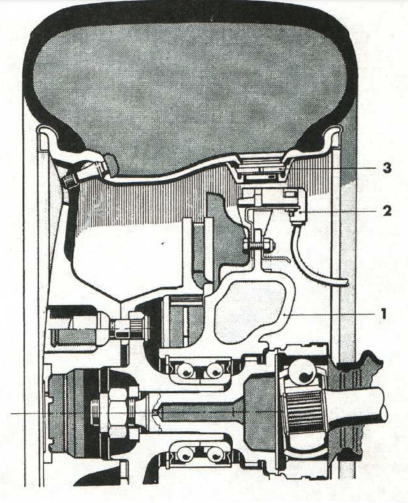

The early system used two sensors mounted 180 degrees apart in special holes in the valley of the wheel. The sensors looked like a stack of poker chips. A diaphragm inside the sensors connected to switches that were set to a reference pressure. The receiver was mounted on the knuckle and was an inductive coil that would pass current through the sensors. Depending on the position of the diaphragm and which switches were open or closed, the amount of current flowing through the receiver’s coil would change.

The disadvantage with this early tire pressure monitoring system is the wheels had to have a large hole for the barrel of the wheel for the sensor. Also, the inductive sensor mounted to the knuckle could easily be damaged by road debris.

In 2004, Porsche started to use a conventional TPMS system for the Cayenne and select Boxster and 911 models. These systems were a lot like those found on BMW, Mercedes-Benz and Audi vehicles. The best way to tell if a Porsche has TPMS is to look for metal valve stems. Sensors can last up to 10 years and up to 100,000 miles. But, the life of the sensor can change depending on the tire pressure sampling frequency and temperature extremes.

Many Porsche models have eliminated the spare tire for weight savings. In place of the spare is an inflation pump that can inject sealant into the tire to seal a puncture. The sealant is designed to be compatible with the sensors and should not clog the pressure port on the body of the sensor. The sealant canister has a limited life. Check the service schedule for the replacement interval of the sealant. The typical interval for replacement is three or four years.

Diagnostics

Porsche TPMS systems use four antennas mounted in the wheel wells and a designated module for the tire pressure. The sensors use a 433mHz and 315mHz frequency. On most models, the menu will have the option for two sets of tires and sensor IDs for summer and winter tires.

You can read the remaining lifespan of the battery capacity of the TPMS sensor using some TPMS tools. The value you read out gives an indication if a sensor needs to be replaced.

The system has a telltale malfunction indicator light and a low-pressure light. When the system detects a malfunction, the telltale light will flash for approximately one minute, and will then remain continuously illuminated. This sequence will continue upon subsequent vehicle startups, as long as the malfunction exists.

If a sensor is not transmitting, the warning light in the speedometer flashes for one minute, and then remains continuously illuminated. Codes and data from the TPMS control module can be accessed with a TPMS or scan tool. If there is a problem, it is typically communication errors with the four receivers in the wheel wells.

It is also important to remember that the TPMS module starts hunting for sensor signals the second the ignition is turned on. Leaving the ignition in the “on” position when a wheel is removed may cause the information display to say, “Wheel change? Input new TPM settings.” Also, if the second set of wheels is in the vicinity of the vehicle, the same warning could be set.

Relearn Process

Before starting any relearn process, set the tire to the pressure specified in the doorjamb for the cold temperature. The relearn process starts with turning the ignition on, accessing the vehicle’s computer and entering into the tire pressure control menu. On most models, you will need to select the winter or summer set of tires. The system will then start to learn the sensor IDs and positions.

The onboard computer displays the message “TPM is learning.” The process may take 2 to 10 minutes, and the vehicle speed needs to be above 15-16 mph. During this time, the current tire pressures are not available on the display. The tire pressure warning light will remain lit until all wheels have been learned.

Position and pressure information will be displayed as soon as the TPMS system has assigned the wheels identified as belonging to the vehicle and to the correct wheel positions.

If the Porsche you are working on has custom wheels, mounting the valve stem and sensor can be challenging. Most valve stem holes come in a few sizes, with the most common being 0.453 inches and 0.625. For TPMS valve stems, the size of the hole can be larger for some snap-in and clamp-on holes, but the real problem can be the anatomy of some custom wheels. The valve stem areas may not have the correct size and shape, affecting how a TPMS valve stem seals. And, some custom rims can have drop centers, barrels and flanges that don’t match up with the original rim or TPMS sensor. But there are some options to address this.