The new Nissan 2.0 L VC-Turbo (Variable Compression Turbo) offers similar performance figures to the 24-year-old 3.5 L V6 that it replaces, while providing 4-cylinder fuel economy. The first vehicle to receive the engine in the Nissan lineup will be the 2019 Altima SR. While it might be a few years before this engine is in your bays, the preparation and training needs to start now, not when you are stumped with a problem.

What sets the VC engine apart is the world’s first production variable-compression turbo engine. The technology was more than 20 years in development and is a breakthrough in combustion engine design as it continually adjusts its compression ratio to optimize power and fuel efficiency. It is projected to offer a double-digit percentage increase in fuel economy.

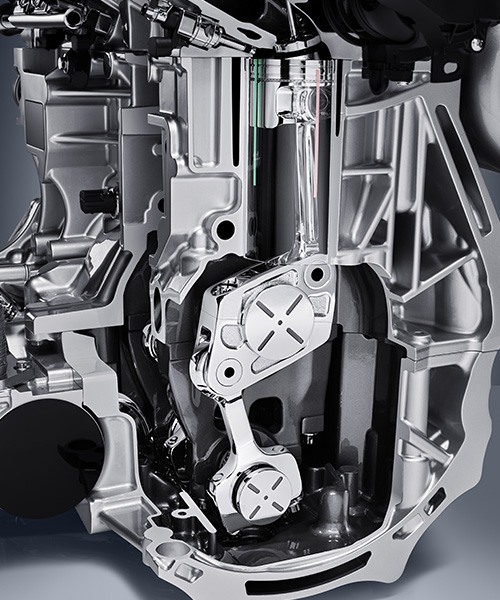

The VC-Turbo changes its compression ratio through an advanced multi-link system that continuously raises or lowers the pistons’ reach to alter the compression ratio for varying loads and engine speeds. A high compression ratio provides greater efficiency, but, in certain applications, it poses the risk of premature combustion (knocking). A low compression ratio allows for greater power and torque and prevents knocking.

As the angle of the multi-link arms changes, it adjusts the top-dead-center position of the pistons and the compression ratio with them. An eccentric control shaft changes the compression ratio of all the cylinders at the same time. As a result, the engine capacity varies between 1,997 cc (for a low 8:1 ratio) and 1,970 cc (for a high 14:1 ratio).

In operation, the VC-Turbo engine offers a compression ratio between 8:1 (for high performance) and 14:1 (for high efficiency). The engine delivers 248 horsepower @ 5,600 rpm and 273 lb.-ft. of torque @ 4,000 rpm (premium fuel). The VC-Turbo’s specific power output is higher than many competing turbocharged gasoline engines and comes close to the performance of some V6 gasoline engines. The unit’s single-scroll turbo ensures immediate accelerator responses on demand.

Along with the world’s first multi-link system, the engine features an electric motor with a unique Harmonic Drive reduction gear to manage the variable compression ratio. The electric motor is connected to the Harmonic Drive with a control arm. As the Harmonic Drive rotates, the control shaft at the base of the engine also rotates, moving the multi-link system within the engine.

The transformative multi-link components are manufactured in high-carbon steel alloy. The engine also utilizes two combustion cycles with electronic variable valve timing, allowing the engine to switch between Atkinson and regular combustion 3 cycles. This allows for greater efficiency and optimal performance as the compression ratio transforms.

The VC-Turbo engine uses both multi-point injection and gasoline direct injection to balance efficiency and power in all conditions. Direct injection improves combustion efficiency and performance and enables the engine to avoid knocking at higher compression ratios. The port fuel injectors also help reduce carbon deposits on the intake valve that have become a big problem with some direct-injected engines.

The multi-point injection system mixes fuel and air earlier, enabling complete combustion in the chamber for greater efficiency at low engine loads. The engine switches between both at regular engine speeds, with both sets of injectors able to work in conjunction under higher loads.

In addition, a low-friction mirror bore coating contributes to a 44% reduction in cylinder friction, according to Nissan engineers, allowing the engine to rotate more smoothly. The coating is applied to the cylinder walls by a plasma jet, then hardened and honed to create ultra-smooth cylinder walls. Providing oil to the engine is a two-stage variable displacement oil pump that raises the oil pressure as engine speeds rise and the compression ratio falls.

Vehicle owners will not understand this technology. The only way they will know it is on their vehicle may be by the window sticker and a screen in the infotainment system that displays the position of the variable compression system. Nissan executives claim no special maintenance will be required. But, in the real world, technicians know conditions are less than optimal and problems can stack up to cause a catastrophic condition like low-speed pre-ignition, or customers who decide to drive with the check engine light on for months at a time.

Base Innovation

For the base 2.5 L direct-injected 4-cylinder engines, Nissan has introduced a new technology to combat carbon deposits. The engine uses thermal-insulated resin intake ports. The design for the port uses an air layer to help keep fresh intake air cold and prevent hot spots, that promote carbon buildup, from forming.

Nissan also is integrating the exhaust manifold into the cylinder head. The carmaker is doing this for two reasons. First, the shorter the distance from the exhaust port, the hotter the gases to light the catalytic converter during open-loop operation.

Second, the integrated exhaust manifold design is more compact and allows for better packaging under the hood so that the engine can be mounted lower in the engine bay.

What does this mean for your shop?

1. Electrical and Electronic Training: The actuation of the variable compression system is performed by an electric motor. The actuation of this motor is likely performed with a very specific signal. Also, there are two or more position sensors to check the position. A scope will be required to diagnose the system to make sure it is operating smoothly. The skills needed to measure the operation of these components can’t be replaced by shot-gunning parts at the car, due to the labor involved and the price of the parts.

2. Connected Systems: The Nissan VC system is not a stand-alone system. It uses multiple sensors to determine if a correction to the compression ratio was effective, and it works in conjunction with fuel and ignition to optimize the performance of the engine. Every sensor input from the gas pedal to the oxygen sensor is necessary to keep the system operational and the check engine light off. Being able to interpret the service information to obtain operational intel and wiring diagrams for testing will be critical when repairing one of these engines.

3. Others Will Follow: Variable compression is the Holy Grail for engineers looking to design engines that are both powerful and efficient. Saab tried to develop a hinged-head engine in the early 2000s, and many other automakers are developing systems that will soon see production. The knowledge obtained from Nissan’s example will transfer over to other vehicles in the future.