Compression Misfires

Compression misfires are most often caused by leaking intake or exhaust valves, mechanical valvetrain failure or incorrectly timed camshafts. Diagnosing an intermittent compression misfire can be tricky if the problem is caused by a marginal failure like a carboned-up intake valve seat or a broken valve spring.

In either case, the misfire might occur only under specific operating conditions. Engines equipped with variable valve timing (VVT) generally cause misfires on a single cylinder bank of a V-type engine if a cam phaser or solenoid intermittently sticks in position. On rare occasion, a sticking exhaust valve caused by insufficient valve stem oil clearances or a weak valve spring can also cause a very intermittent loss of compression and cylinder misfire.

Timing Issues

Obviously, over-advanced ignition timing can cause cylinder misfires. Excessively retarded valve timing won’t cause a misfire, but will cause a substantial loss of power. But since ignition timing on most modern ignitions is non-adjustable, any failure in ignition timing would be caused by a computational error in the ECM. Computed valve timing problems are less of an issue because an appropriate DTC is stored in the ECM’s diagnostic memory.

Scan Tool Tips

As mentioned earlier, the general causes of a misfire fall under the headings of 1.) ignition, 2.) fuel, 3.) compression and 4.) timing. Always begin any intermittent misfire diagnosis by using your professional scan tool to retrieve misfire codes and freeze-frame data. When diagnosing intermittent misfires, don’t forget to look at pending codes for indications of an individual cylinder misfire.

If your scan tool’s misfire history indicates multiple cylinder misfires, focus on the cylinder with the most misfire counts. The misfire counts on adjacent cylinders are often “sympathetic” misfires that will often disappear when the primary misfire is repaired.

Short-term fuel trim (SFT) numbers can be used to determine if the misfire is caused by lean or rich a/f ratios. Normal SFTs running about plus or minus 5%, or even as high as 10%, might not indicate a problem. But, for example, if the SFT is running high positive numbers at idle and returns to zero as the engine speeds up, you’re probably looking at a vacuum leak.

As mentioned earlier, negative SFTs indicating a rich A/F ratio might produce a rough idle, but won’t always produce a P0300 code. Keep in mind that the downstream, post-catalyst oxygen sensor can often be used to differentiate between an ignition- or fuel-related misfire. To illustrate, a misfire caused by a lean A/F mixture will drive the downstream voltage lower because an excess of oxygen is passing through the catalytic converter. In contrast, an ignition misfire will drive the downstream O2 voltage higher because raw fuel and oxygen is being oxidized in the catalytic converter.

Labscope Tips

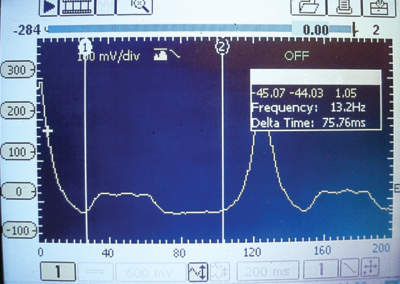

Labscopes can be used to display secondary ignition waveforms through a special inductive probe. If you’re testing primary ignition, you should use an attenuated test lead to avoid damaging your scope. In any case, secondary waveforms are valuable for detecting bad spark plug wires and ignition coils. If available, your “movie” feature can be used to more easily detect intermittent cylinder misfires.

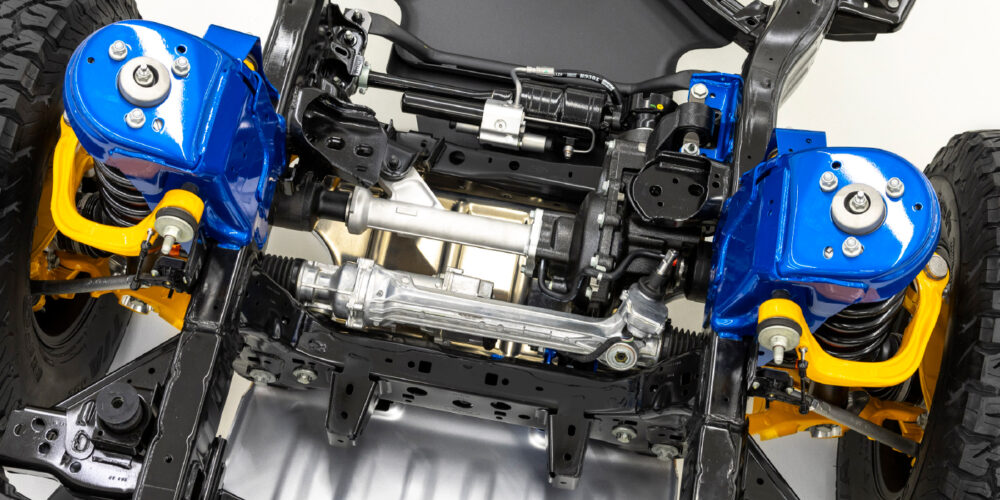

Current ramping the primary ignition system by using a low-amperage current probe to display the current rise through the coil primary circuit is the best method to detect a bad ignition coil because it’s non-invasive and provides a far more accurate indication of coil performance than do most primary or secondary displays. See Photo 3.

In-cylinder pressure transducer testing is an excellent method for accurately testing running compression and camshaft timing. While space doesn’t allow a more detailed explanation of scan tool and scope diagnostics, keep in mind that many excellent training books and videos are available through several reputable aftermarket suppliers. Practice makes perfect and collecting known-good data in your scan tool or scope memory for future reference is the best way of recognizing the various causes of an intermittent misfire. See Photo 4.

Propane Testing

When used with care, introducing propane into the intake system to enrich the A/F ratio is a quick and generally efficient method for diagnosing fuel density misfires. In brief, adding fuel will temporarily correct a lean-fuel condition caused by a vacuum leak or clogged fuel injector. Remember that when propane is added to intake air, the lean cylinder will return to normal, while the remaining cylinders will run slightly rich. Keeping it quick and simple is often the best way to diagnose any fuel-related intermittent misfire.