One of the most rewarding things about being an import specialist tech is overcoming different repair challenges on a daily basis. There are few professions that demand such a diverse skill set to be put to use every day. On any given day, you might be required to serve as an air conditioning tech, use your knowledge as an electronic expert to repair harnesses or diagnose CAN communication issues, or utilize your plumbing skills to replace a rusted brake line. On many jobs, you’re using multiple skill sets to complete one job, which may be the case when doing undercar work on Hyundai cars and SUVs.

The majority of undercar complaints will usually be noise related and range from a knocking noise on rough roads, a scraping noise when braking or a clicking noise while turning. Some complaints will include vibrations in the steering wheel and from under the seat.

The first step with any of these complaints is to do a road test to confirm the customer’s complaint. This is also a good time for the tech to get to know the customer, which is never a bad idea since it helps build trust in your shop. It also reminds the tech that every car you work on has a person attached to it who is relying on your work to deliver a good value, an accurate repair and a safe vehicle.

There are a lot of times when the tech will pick up on a problem that the customer may not have noticed. The most common of these are wheel bearing noises that have come on gradually but haven’t reached the level to get the customer’s attention. My shop doesn’t push for a sale if the bearing is making a slight noise, but we will certainly point it out as a potential safety problem that will get worse. We also emphasize that any increase in noise level should result in the vehicle returning for service. Of course, if the current repair has you removing the axle or brake rotors, it may make sense to take care of both problems to save the customer some money on labor.

BEST PRACTICES

While most of us are familiar with diagnosing undercar problems, I’ll lend some best practice strategies that should be helpful to you. The first and most important is performing a quick safety inspection on every car that goes up in the air. In less time than it takes me to type this paragraph, you can walk around the vehicle and get a look at the brake pads and rotors and spin the wheels for unusual noises or excessive drag.

You can also push the wheels side to side to look for tie rod end or ball joint play, and rock the wheels to look for excessive play in the wheel bearings, struts and ball joints. Many times, it’s hard for the driver to notice looseness in the steering components, so it’s our responsibility to point out these issues. In a case like this, you’re not upselling the job, you’re providing a safety-related service that the customer needs.

If your shop is in a Rust Belt location, keep your eyes open for rust and corrosion damage to control arms, subframes, chassis components or other areas where the environment can take its toll, as some component damage could be more critical than others. For instance, a control arm failure would be catastrophic at speed. This is less of a problem on later models, but there are plenty of 10-year-old Hyundais on the road on which this type of failure could be a possibility.

One of the most common suspension problems we find on these cars involves sway bar mounting bushings and links. Oftentimes, the customer thinks these problems are strut related and you’ll have a customer call you up asking for a price on the struts. My first question to these folks is, “Why do you think you need struts?” Many times, it will be a noise issue provoking people who have been told they need struts by mass marketers. I don’t give them the price; instead, I ask that they bring the car in so we can properly diagnose the problem and give them an accurate estimate. To better identify the suspension noises, we will rock the vehicle side to side. We find this to be more effective than the simple bumper-push test since it will unload and load the suspension.

On To The Brakes

We can’t talk about undercar service without mentioning the brake system. Over the years, I have covered Hyundai brakes many times, and I continue to believe that the most important component in successful brake service is good work habits. Protect the ABS unit by opening the bleeders before you push back the caliper pistons to let the dirty fluid dump into the bleed bottle rather than push it back into the system. Be sure to clean and lubricate the brake hardware to ensure the ABS and vehicle stability systems function as designed. Hyundai has adopted emergency self braking where the vehicle can apply full braking power up to 50 miles per hour based on camera and radar input, so let’s be sure these systems function as designed.

When replacing the rotors, take a few minutes to clean the hubs and finish bleeding all four calipers to be sure the fluid is fresh. Also, torque the lug nuts to the proper spec.

Hyundai has a good track record with ABS systems, and we really don’t see a lot of problems with them. Most issues are related to wheel speed sensor failures and tone ring problems. It’s our experience that when a sensor fails, you will not see any speed on your scanner when looking at those parameters on a road test. If you have a loose or broken tone wheel, you’ll generally see speed fluctuations and dropouts as you drive.

More often than not, when a customer comes in complaining about the ABS activating or a pedal pulsation, we know it’s associated with ABS activation. Tone ring damage may be evident when one wheel looks like it’s skidding due to the speed dropout. If you suspect a tone ring problem, all it takes is a visual inspection with the push of a screwdriver to see if it moves to confirm that it’s cracked or loose.

Here in the Northeast, tone ring failures are almost always due to rust buildup under the ring. Be sure to clean the surface where the tone ring sits and, if needed, use a tack weld to keep it where it belongs. On some models, the ABS hardware as well as the sensor is included in the hub assembly.

When diagnosing an intermittent ABS and/or ECS lamp, keep in mind that there was a problem around 2010 where Hyundai recalled some vehicles for an intermittent brake light switch problem that contributed to failure warnings. Check your TSBs, but if you are in doubt, I would recommend a new switch.

The ABS system is critical to the operation of the Electronically Control Suspension (ECS) system. So, if there is a problem, you can expect that the customer will notice the ECS light will be illuminated along with the ABS lamp since the ECS will not operate without dependable signals from the ABS system.

On the newer models, Hyundai has gone to Electronic Brake Force Distribution (EBD). To get the maximum brake performance available, this system incorporates the ABS system to maintain the proper brake balance between the front and rear brakes. In the past, this function was always handled by the hydraulic proportioning valve, and it was a compromise at best. By incorporating the ABS system to monitor the slip of the rear wheels, the braking performance is greatly improved.

If a failure exists, an EBD lamp will illuminate on the dash along with the hand brake lamp to get the driver’s attention. That’s all the more reason to practice good work habits when performing brake service. It’s hard to envision this system working well with excessive mechanical drag in the brake hardware or with debris in the ABS unit.

Case Study

Just recently, we had to deal with a steering issue on a late-model Elantra with electronic power steering.

The customer dropped the car off after complaining that it seemed like the car would steer all by itself. On the road test, we noticed that the car did seem to overreact to steering input, where a minor input to the steering wheel resulted in an exaggerated change of direction. We also picked up on a knocking noise that sounded like it was coming from the steering column when the steering wheel was turned side to side. He didn’t mention that on his note or during our phone conversation. When we told the customer about our findings, his reaction was, “Now that you mention it, there was a slight noise.”

When I assigned the job to the tech, we talked about what we should be looking for during our inspection. I suggested he look for free movement or looseness in the steering, mentioning that the noise could be in the steering shaft U-joint. I reminded him to be sure the rear suspension had no play, which would cause rear steer.

If everything checked out fine, we’d inspect the front and rear toe and, of course, the condition of the tires. After finding no play in the system and that the toe was in spec, he disconnected the tie rods to confirm that both wheels steered with no resistance in the ball joints or strut mounting.

ELECTRIC POWER STEERING

During this inspection, we confirmed that the noise was in the electronic power steering column. Hyundai’s official name for the system is Motor Driven Power Steering (MDPS).

We weren’t very familiar with the MDPS system, so it was time to do some research to see if the wandering problem could be tied to the noise issue in the steering column, and, if so, how we were going to deal with it. The first step was to take a look at online service information. It didn’t take long to find TSB #14-ST-002-1.

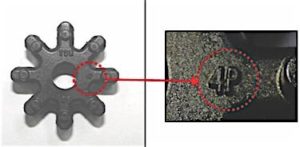

This TSB deals with the drive coupler between the assist motor and steering shaft. These couplers have been failing and resulting in excessive clearance between the motor and shaft. There have also been reports of metal-to-metal contact causing the noise as the lash is closed up. Could this play be contributing to our wander problem?

First, we looked at how the system worked. In the simplest terms, the steering control unit takes inputs from the steering angle/torque sensor and vehicle and engine speed sensors via a CAN signal from the engine ECU and assist motor position. Using these inputs, the control unit sends out a signal to operate the steering motor, providing the necessary assist. All the components are located on the steering column.

As we looked for information, we stumbled upon a good video that showed how the system worked. We don’t have the space to go into a lot of detail, but I would like to share some interesting items about the system.

The steering angle torque sensor serves as the “brains” of the system when it comes to inputs. The steering shaft incorporates a torsion bar monitored by two discs on either side of the bar with windows that have lights passing through them. By looking at the shadows generated and the relationship of the discs, the ECU can determine the direction, force and speed of the steering input and command the assist motor as needed. The maximum draw of the motor is 78 amps, unless the steering is at full lock, where it’s cut in half to prevent overheating the motor.

The steering angle torque sensor serves as the “brains” of the system when it comes to inputs. The steering shaft incorporates a torsion bar monitored by two discs on either side of the bar with windows that have lights passing through them. By looking at the shadows generated and the relationship of the discs, the ECU can determine the direction, force and speed of the steering input and command the assist motor as needed. The maximum draw of the motor is 78 amps, unless the steering is at full lock, where it’s cut in half to prevent overheating the motor.

Getting back to our wandering Elantra, it appeared to us that with the bad coupler on the motor, the steering assist wasn’t keeping up with minor steering inputs. This caused the driver to increase the input, resulting in an overreaction of the steering.

A call to the dealer confirmed that the problem would be covered by Hyundai, so we suggested to the customer to have the coupler replaced to take care of the wandering problem (and it did).

While we didn’t have to perform the repair, we did research it in the event we were going to do so. Like any good techs, we also wanted to check into it to serve our mechanical curiosity. The process is straightforward, and I don’t believe any experienced tech would have a problem installing this coupler. The TSB goes into the details and is well outlined with illustrations — some of which are used in this article. When the job is completed, plug in your enhanced scanner to be sure there are no codes and that the steering angle sensor is centered. If you want to know more, a quick Internet search will lead you to some good videos that do a great job of explaining the system.

There is no reason not to welcome Hyundais into your bays with any repair or service need. If you are equipped with an enhanced scanner, a good Internet connection and a bit of mechanical curiosity, it will be a good experience for your client and the shop. It doesn’t get any better than that.