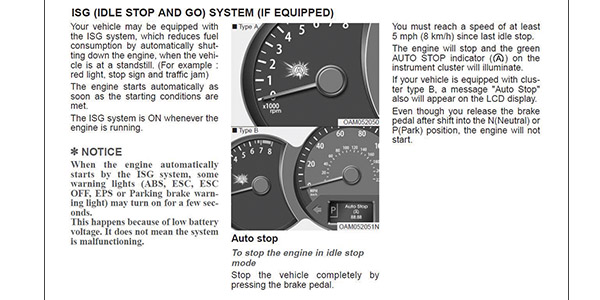

The Hyundai Idle Stop and Go (ISG) function is the automaker’s start/stop system that found its way onto some 2012 models. ISG automatically switches off the engine when the car is at a standstill and starts it again as soon as the brake pedal is released.

A lot has to happen for the engine to utilize ISG. Specific conditions with the engine, transmission and brake system all have to be met for the ISG system to function.

Battery Conditions

When the engine stops, so does the alternator, so the battery must run the HVAC, infotainment and other systems with no disruption. Hyundai typically specifies an aggregated glass mat (AGM) battery for vehicles equipped with the ISG system. The correct AGM battery usually fits in the same location as a vehicle that is not equipped with an ISG system. Also, the BCI group size might be the same. The best way to order the correct replacement battery is to look at the old label for cold cranking amps (CCA) and reserve capacity (RC). The replacement battery should meet or exceed these specifications.

The ISG system also measures the health of the battery in two ways. First, it measures the battery’s state of charge (SOC) with a current and voltage sensor on the positive battery terminal. The temperature of the battery is measured with a sensor mounted on the positive battery terminal. If the battery is below 77% SOC, ISG will not work. And, if the battery temperature is below 35° F or above 133° F, the ISG will not shut down the engine. Also, if the system detects a crank that’s longer than two seconds, the ISG system will be deactivated.

Engine and Cabin Conditions

An ISG engine will not switch off the engine if it is too cold or hot, inside and outside. The coolant must reach 174° F so the engine can get to operating temperature as quickly as possible to reduce startup emissions. Coolant temperature is also critical for the passengers in the cabin. The system will also look at the ambient temperature sensor’s data.

The ISG system will work only when ambient temperatures are between 28 and 95 degrees. This is done for driver comfort so they are not freezing in winter or roasting on the hottest summer days. Under certain conditions, if the blower fan for the HVAC system is set to MAX or defrost, the ISG will not shut down the engine.

Brake Conditions

The ISG uses both the brake pedal position sensor’s information and the pressure transducer on the brake booster to perform an auto stop or start. The vacuum in the booster needs to be below -35kpa. The ISG will force a restart when the engine goes above -35kpa.

If there is not enough vacuum, the pedal will sink and the booster will not be available to produce enough assist if the driver needed to stop suddenly after the restart. Also, if the vehicle does not go faster than 5 mph after a stop/start event, the engine will not shut down again.

The yaw, lateral accelerometers and steering angle sensors are also used by the ISG system. If the car is stopped on a slope that is greater than 12 degrees uphill or downhill, the ISG system will not stop the engine. Also, if the steering angle sensor reads more than 180 degrees in either direction, it will not shut down the engine.

Code Conditions

The most common cause of ISG deactivation is the presence of codes stored in modules. Codes for sensors in the cooling, brake and battery systems will stop ISG operation. Also, codes for CAN bus communication will stop ISG operation because the ISG module needs to communicate with the ECM, Transmission and ABS modules.

Diagnostic Tips

1. If the engine has to perform a forced restart, the ISG light in the instrument cluster will flash for five seconds.

2. If you have to shut the hood with the engine running and are planning to go for a test drive, restart the vehicle with the key. The ISG system will not work if the hood is opened during the drive cycle. This is a safety feature to prevent a technician from being injured.

3. In some cases, if you are testing emissions monitors or testing the EVAP system, the ISG system will not work again until the scan tool is unplugged.