Honda uses a specific bearing selection process for both rod and main bearings. It includes using a chart along with the identified parts included in the engine being rebuilt. Connecting rod bearing selection uses four possible rod journal codes to match with four big end bore codes that are color coded based upon size. A quick check against the chart finds there are 16 different rod bearing sizes (colors) that are possible with the identification color on the edge of the bearing. While this may already seem somewhat confusing, it gets slightly more complicated. Following the chart you may have to mix bearing halves to achieve the correct selection. When mixing bearing halves as directed it does not matter which color is on the top or the bottom.

Honda uses a specific bearing selection process for both rod and main bearings. It includes using a chart along with the identified parts included in the engine being rebuilt. Connecting rod bearing selection uses four possible rod journal codes to match with four big end bore codes that are color coded based upon size. A quick check against the chart finds there are 16 different rod bearing sizes (colors) that are possible with the identification color on the edge of the bearing. While this may already seem somewhat confusing, it gets slightly more complicated. Following the chart you may have to mix bearing halves to achieve the correct selection. When mixing bearing halves as directed it does not matter which color is on the top or the bottom.

Big end connecting rod tolerance can range from 0 to 0.024mm (0.0009˝) in 0.006 mm (0.0002˝) increments, depending upon size of bore on the big end. Each rod is stamped with a number or bar (1, 2, 3 or 4/I, II, III, IIII), which indicates range. Just as with the pistons, an engine may have any combination of numbers and bars. To aid in reassembly the number or bar is split with half being on cap the other being on the rod itself; ensure these numbers are whole when reassembling. If reading the code is difficult due to oil and varnish staining, clean only with solvent or detergent. Using a wire brush or scraper can remove the code. Normal big end bore size is 51.0 mm (2.01˝).

Under warranty Honda has its technicians measure rod bolt length for reuse as the bolts are torque to yield. To perform this measurement, the bolt diameter is measured at two places; 35 mm (1.38˝) from the bottom of the bolt head and 20 mm from the bottom of the bolt head (0.79˝). Some quick math is done and compared to the specification on diameter difference of 0-0.1mm (0-0.004˝). Ideal for a rebuild no, but it is in the service manual so now you know as well.

Main Bearing Replacement

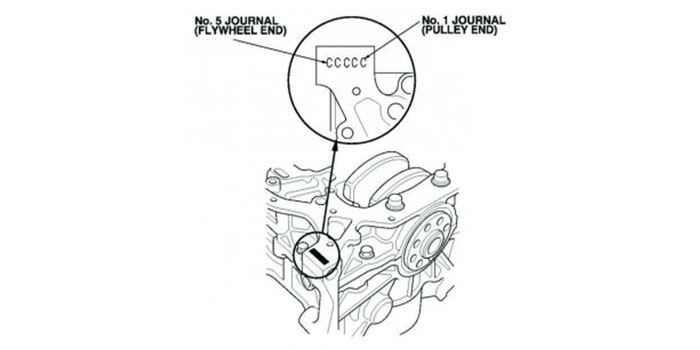

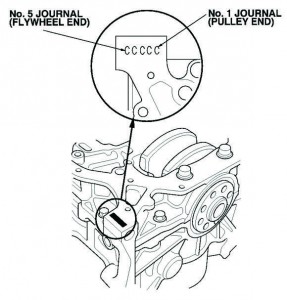

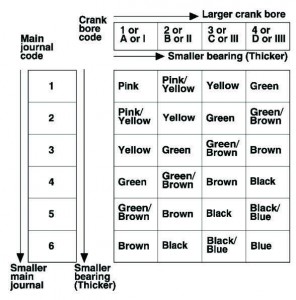

Just as with the rod bearings, Honda utilizes the same chart-based selection process of numbers/letters to fit the five journals with the correct color-coded bearing. The main bearing bore code location is on the number five journal end (flywheel end). Number one journal end is on the pulley end. The main journal location code is stamped on the crankshaft counterweight directly below the rod bearing code. Removal of the engine girdle greatly enhances the ability to properly read the codes. Main bearing possibilities are 24 in total. Just as with rod bearings either a single color or a mixture of two different bearing colors may be used. Placement in top or bottom does not matter.

Just as with the rod bearings, Honda utilizes the same chart-based selection process of numbers/letters to fit the five journals with the correct color-coded bearing. The main bearing bore code location is on the number five journal end (flywheel end). Number one journal end is on the pulley end. The main journal location code is stamped on the crankshaft counterweight directly below the rod bearing code. Removal of the engine girdle greatly enhances the ability to properly read the codes. Main bearing possibilities are 24 in total. Just as with rod bearings either a single color or a mixture of two different bearing colors may be used. Placement in top or bottom does not matter.

You must measure two different main bearing-to-journal oil clearances depending upon the journal you are checking.

Main Bearing-to-Journal Oil Clearance Specification

Number 1, 2, 4, 5 Journals:

• Standard (New): 0.017-0.04 mm (0.0007-0.0016˝)

• Service Limit: 0.050 mm (0.0020˝)

Number 3 Journal:

• Standard (New): 0.025-0.049 mm (0.0010-0.0019˝)

• Service Limit: 0.055 mm (0.0022˝)

Reassembling the Block

Install the correct bearing halves per chart selection for both the rod and main bearings. Ensure that the numbers stamped onto the rods are complete so the caps are not reversed. Rod bolts are torqued to 2.0 Nm (14 lbf/ft) then an additional 90°. If by chance you pass the 90° angle, remove bolt and measure bolt diameter again to ensure bolt is not stretched. As with most modern engines, machined surfaces are sealed with a liquid gasket material that should be assembled in four to five minutes. Otherwise clean off and reapply the sealer. Attach the lower block (girdle) onto the main block and torque the main bearing caps from the inside out, alternating sides to 29 Nm (22 lbf/ft). After all main cap bolts are torqued, tighten an additional 56°. Next torque the 14 lower (8 mm) block-to-the main block bolts to 22 Nm (16 lbf/ft).

Courtesy Engine Builder.