Headlights are continually evolving to keep up with safety and styling. In 1979, when Import Car was first published, about eight sealed beam headlight part numbers could cover 99% of the imports on the roads. In the 1990s, the headlight bulb became part of an assembly mounted flush in the front end. Soon came halogen and other exotic gases to improve contrast and light output.

In the 2000s, many sport and luxury import nameplate vehicles utilized high-intensity discharge (HID) lighting. Now, HID or Zenon technology is being replaced by LED headlights. But, there are a lot of European vehicles out there with HID lights. Here are five diagnostic tips to resolve issues with these systems.

HID Diagnostic Tips

1. Start with a scan tool: Many HID headlights have modules integrated into the ballast components. If the bulb, module or ballast is not working, it might generate a code. Some problems might be related to a loss of communication with the network used to control the lights.

2. Never assume it is just the bulb: With halogen bulbs, the most expensive premium bulb will cost $35. HID bulbs can cost more than $95. Installing a bulb only to find out it is the ballast module can end up costing two or three times that amount. If a visual inspection reveals a blackened or cracked bulb, replacement might be necessary.

3. Testing the HID systems: HID bulbs can’t be tested with an Ohm meter because there is no filament, only Xenon gas. Connecting a voltmeter to the ballast resistor is not advisable unless you have a high-voltage set of test leads. It would be like trying to measure voltage passing between the electrodes of a spark plug with your voltmeter.

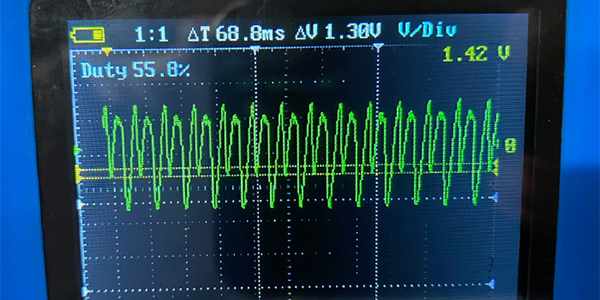

HID systems generate thousands of volts to ignite the Xenon in the bulb and then lower the voltage for normal operation. This amount of current is very low. If you can access the harness, you can install an amp clamp between the bulb and ballast. You will see a big spike and the current will level out.

4. Look at power and grounds: For the ballast to work and the gases to ignite, it requires a clean and constant voltage supply. If the alternator has excessive ripple or AC voltage, it can cause the ballast unit to malfunction. Also, ground connections can become corroded because they are typically exposed to salt spray. If the unit does not have a good ground, the system voltage can’t reach the ballast unit.

5. “Not as bright” complaints: Some customers may complain that their headlights are not as bright as before. The bulbs and ballast modules might be operating normally, but the light does not seem as bright. The issue might not be the lights, but where they are aimed. Many HID systems have motors that actively aim the lights. These typically use data from a ride height and steering position sensor. If the data is not there or implausible, the lights will say in one position.