On most vehicles, the primary component of brake dust is material from the rotor — not the pads. When rotors become worn, drivers may experience pedal pulsation. What is the solution? Make harder rotor surfaces. That is what GM, and now Porsche, have done on some of their vehicles.

The hard surface of rotors is less than a millimeter thick. The surface treatment defuses carbon and other metals into the outer surface of the rotor. The old-school name for this is case hardening. The GM name for this is Ferritic Nitro-Carburizing (FNC). Porsche calls it Surface Coated Brakes (PSCB), which deposits a layer of tungsten carbide on the surface.

You may be thinking that the manufacturers could cast a rotor with a different grade of iron or other material that is harder, but this could cause the material to be too brittle. A harder material also might not conduct heat in the same way as conventional iron. This could mean cracks and possibly even brake fade. These surface treatments allow for the best of both worlds.

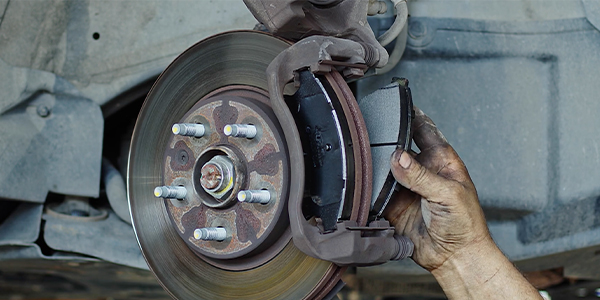

The other technology that makes these harder rotors possible is the pads. These pads are similar to ceramic pads that leave a layer of material on the rotor that is renewed when the pad is applied. This layer keeps wear on the rotor to a minimum, so the surface treatment lasts.

This hardened layer is very thin. If an aggressive semi-metallic pad is installed, it could wear away the layer of hardened material quickly. So, the pad and rotor are matched to each other for optimal longevity and performance.

GM and Porsche are using these surface treatments to increase customer satisfaction. These brakes produce less brake dust and have less of a chance of runout developing into thickness variation that could cause pulsation. For the shop that’s replacing the brake pads or rotors, it begs the question if these types of rotors and pads will be available when the time for replacement comes? Or are these OEM-only fixes so the cars get the best customer satisfaction scores?