There is almost no way to inspect the spray pattern of the fuel injector while it is on the vehicle, and it is impossible to inspect it on a vehicle with direct fuel injection. You can, however, witness the symptoms of a bad injector.

For efficient combustion to take place, the droplets of fuel must be a specific size and properly distributed in the cylinder. The fuel injector nozzle, fuel pressure and the injector’s location have a direct influence on the distribution of fuel in the cylinder.

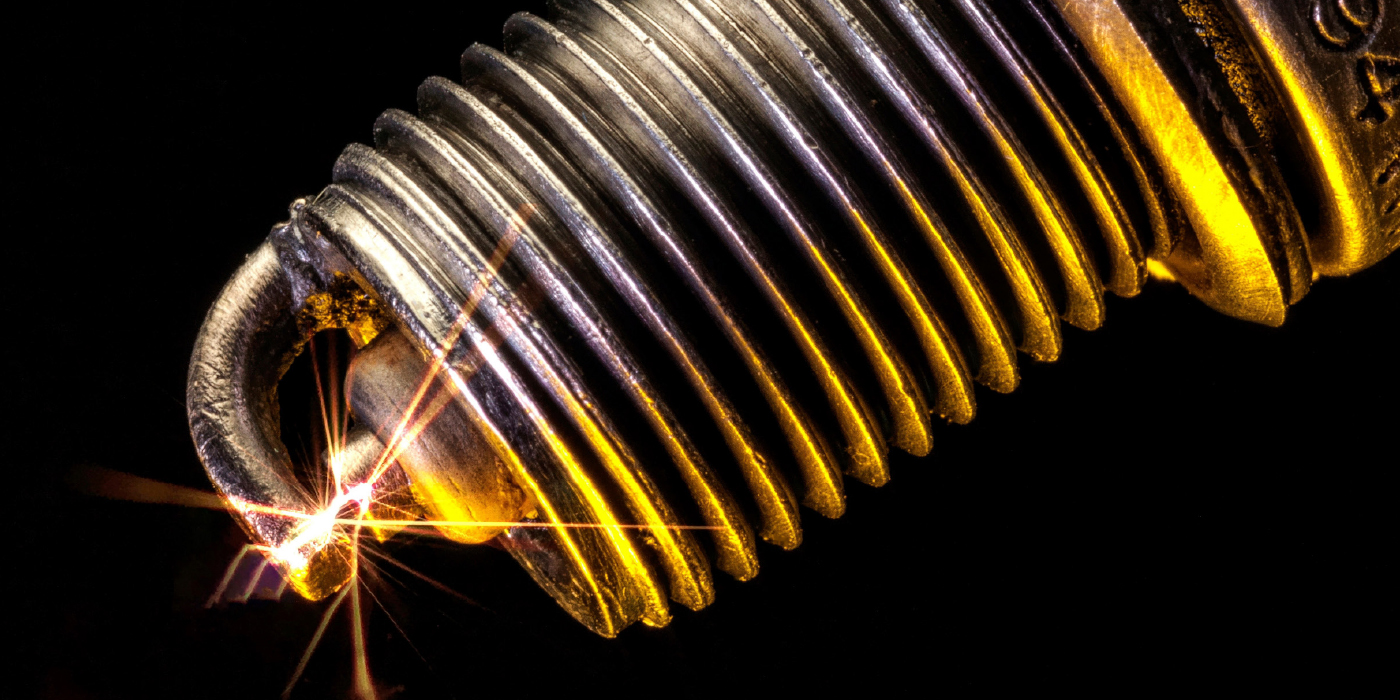

If the droplets are colliding, are the wrong size or the volume is not correct, unfavorable outcomes can occur. First of all, the fuel might not entirely burn. Excess fuel can lead to carbon deposits that, in turn, can cause hot spots and eventually lead to pre-ignition, detonation and knock. If enough incidents occur, damage to the pistons, rings and connecting rods can result.

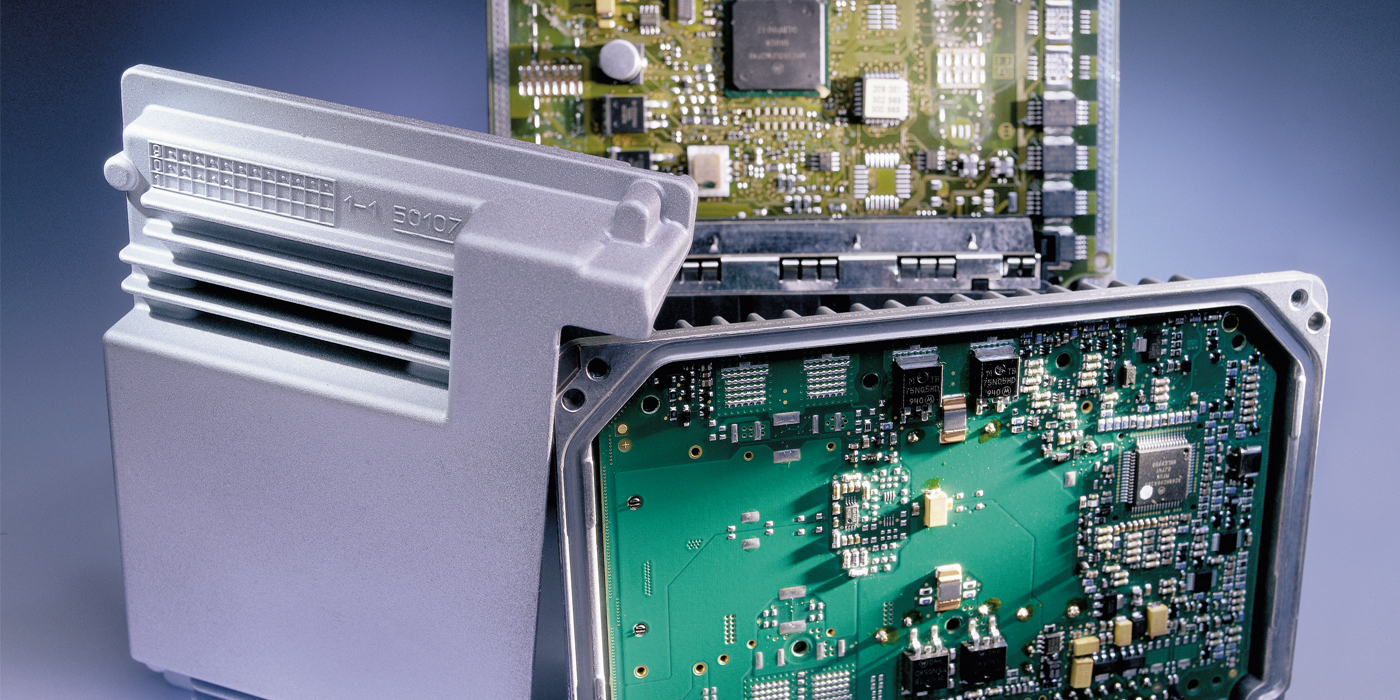

A malfunctioning fuel injector can also damage the catalytic converter. The oxygen sensor does not see unburned fuel; it measures the oxygen in the exhaust gases. If fuel does not burn in the cylinder, the oxygen is not consumed. The engine will try to burn the oxygen by adding more fuel and raising the fuel trim. The ECM can compensate by leaving the fuel injector open shorter or longer, with more or less fuel making its way into the cylinder. This approach can compensate for the bad fuel injector for a limited amount of time and the driver might notice a drop in fuel economy.

According to the EPA, extra fuel can’t go out the tailpipe, so it needs to be burned in the catalytic converter. This is where the downstream oxygen sensor detects that something is not right in the combustion chamber. The converter is using stored oxygen and oxygen in the exhaust stream to catalyze the unburned fuel, due to the differences in oxygen content when compared to the upstream sensor.

WHY DO INJECTORS GO BAD?

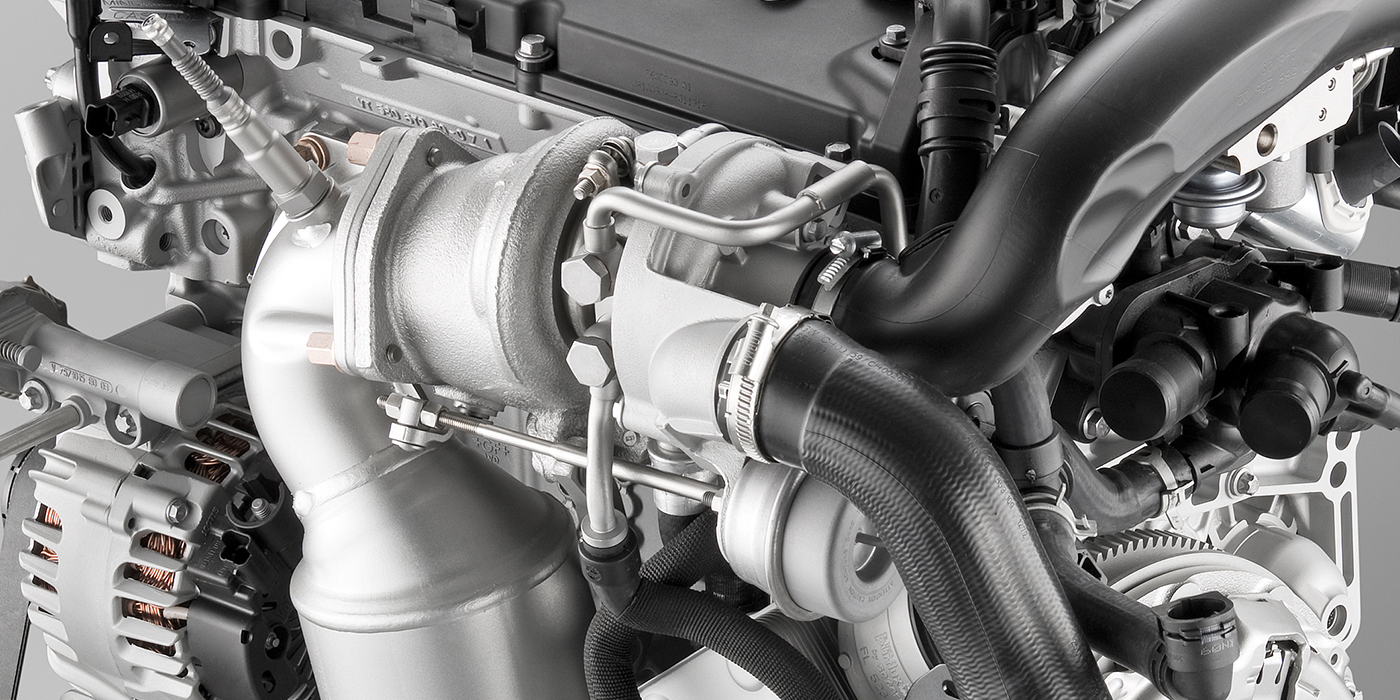

When the engine is shut off, the injectors undergo heat soak. Fuel residue evaporates in the injector nozzles, leaving the waxy olefins behind. Because the engine is off, there is no cooling airflow moving through the ports and no fuel flowing through the injectors to wash it away, so heat bakes the olefins into hard varnish deposits. Direct-injected engines have it even worse because the injector is buried in the block or the head. Over time, these deposits can build up and clog the injectors.

Since the formation of these deposits is a normal consequence of engine operation, detergents are added to gasoline to help keep the injectors clean. But, if a vehicle is used primarily for short-trip driving, the deposits may build up faster than the detergents can wash them away.

DIAGNOSTICS

If you suspect a fuel injector problem, inspect the following:

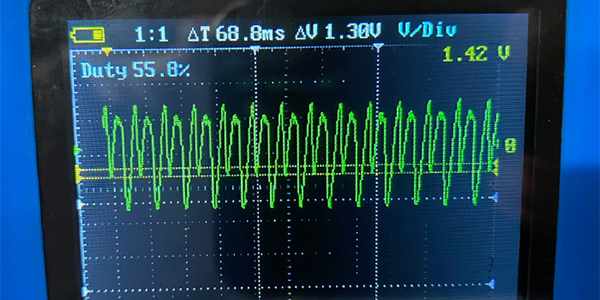

1. Fuel Trims: If the long-term fuel trims are above or below 11% and the engine is having to add or take away fuel, there might be an issue with multiple injectors trying to compensate for leaking, clogging and/or poor spray.

2. Codes: Fuel injector codes can be classified into three categories:

First, electrical trouble codes can indicate that there is a short or open, or the resistive value is off for the injector. Remember, most injectors share the same ground.

Second, misfire codes can indicate an issue with a specific cylinder or random cylinders. If a cylinder is too rich or lean, the combustion event might not take place.

Third, catalyst codes for efficiency will be set because excess fuel could prevent the catalyst from storing oxygen during certain conditions.

3. Fuel Pressure: Most fuel rails try to operate at a constant pressure and will change the fuel injector “open” times to control the amount of fuel being delivered into the cylinder. Lower fuel pressure will change the spray pattern of the injector. Also, if you detect a condition where the engine is starved for fuel (lean) at higher loads and engine speeds, the issue might be the fuel pump.