While old-school cooling system service often focused on coolant leaks and overheating engines, let’s begin thinking “new-school” by looking at modern cooling systems through the eyes of the engine coolant temperature (ECT) sensor. Coolant temperature is important because torque converter clutch engagement, idle speed control, variable valve timing, engine cooling fan operation and various other powertrain functions depend upon the engine coolant quickly reaching full operating temperature. And, more important, ECT is often a primary component of the “enable criteria” needed to run diagnostic monitors and store diagnostic trouble codes (DTCs) and related freeze-frame data.

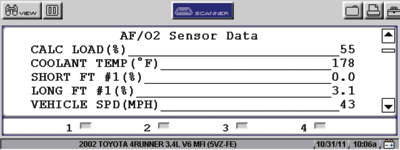

When designing a diagnostic test monitor, automotive engineers create a set of operating conditions (enable criteria) that must exist before the monitor will test the circuit in question. While enable criteria might include engine run time, specific system voltage levels, engine load and other operating parameters, most enable criteria will also include engine coolant temperatures. For example, a DTC for a failed oxygen sensor might not be stored if the engine fails to reach operating temperature. So, unless the ECT achieves full operating temperature within a specified length of time, diagnosing an intermittent or random no-code driveability or stalling complaint is nearly impossible. See Photo 1.

COOLING SYSTEM DESIGN

Modern cooling system design is most often concerned with warming up the engine as quickly as possible and maintaining a constant coolant temperature. As a result, we might be seeing old-technology components like radiator shutters make a comeback on some vehicle platforms. On other platforms, water-cooled exhaust manifolds force engines to reach operating temperature within minutes of a cold-soak start.

Some cooling systems include features like electronic thermostats or even dual thermostat configurations, all of which are designed to shorten engine warm-up times. Some cooling systems use electric water pumps to circulate warm coolant through one or more heater cores to keep passengers warm when the engine is shut off.

Other configurations use an electric water pump to cool the engine’s turbochargers after a hot shutdown. In the near future, I’d look for many of these cooling system innovations to be included in stop-start and hybrid engine technology, and I’d also begin to look for many new cooling system malfunction trouble codes.