Electric power steering is quickly becoming a standard feature on new vehicles, but it’s not an emerging technology. It’s been in the field for the better part of two decades. Now, electric power steering has continued to advance by making autonomous safety features possible.

The evolution of this system has seen a replacement of the hydraulic portion by magnets and armatures in addition to sensor advancement. Some of the current torque sensors can even detect if the driver has removed his/her hands from the steering wheel.

The electric motor has evolved to the point where it can now take control of the vehicle. More powerful motors allow the vehicle to park itself and even nudge a car back into its lane if the system detects a drift due to a distracted driver.

BASICS

When a steering wheel is turned, the steering sensor detects its position and rate of rotation. This information, along with input from a steering torque sensor mounted on the steering shaft, is fed to the power steering control module. Other inputs, such as vehicle speed and inputs from the traction control or stability control systems, are factored in to determine how much steering assist is required.

The control module then commands the motor to rotate a certain amount, and a sensor on the motor provides feedback to the control module so it can monitor the motor’s position.

On older systems, if a sensor or other component in the steering system fails or starts producing out-of-range data, the self-diagnostics should detect the fault, set a code and, more than likely, disable the power-assist. A warning light will illuminate to alert the driver, and the driver will notice a significant increase in steering effort when turning the vehicle. The goal of the system is to prevent overheating and damaging the electric motor.

Most import nameplate vehicles have modes to suit different driving conditions and levels of power assist and feel. These modes can often be observed using a scan tool that can observe the data PIDs for the electric power steering.

Most systems have a mode called normal, operational or standard. In this mode, the steering responds to driver inputs measured with a steering angle sensor and torque sensor, and provides steering assist that is required for the vehicle’s speed.

Some systems have a return mode to improve the self-centering characteristics of the suspension to assist steering return after completing a turn. Information from the steering position sensor prevents the system from overshooting the center position.

Other systems have a mode to minimize bump and torque steer. In this type of mode, the electric motor acts like a hydraulic dampener to prevent kick back and steering pull. It uses speed and steering wheel position information to determine the needed amount of dampening. Sometimes, the steering will enter this mode while the vehicle is parked with the engine on, and the driver might notice small movements in the wheel. This mode will also look at throttle and yaw inputs to determine if a torque steer event is taking place.

Most important is the protection or safe mode, which detects and estimates excessive or long periods of current draw that could burn out the motor. This can occur if the steering wheel is held at a locked position for a long time, or if the information from the steering angle sensor is erroneous. In some cases, if the sensor has an incorrect steering angle, a high road crown can cause the system to overheat.

All systems perform a self-check when the vehicle starts to confirm signals and communication with the other modules, and it will check the sensors with a bias voltage or measured resistance to determine the heath of the sensors. If the steering module detects a problem, it will put the system into a safe mode that provides a set level of assist. In some cases, the electric power steering system will deactivate.

ADVANCED SYSTEMS

More advanced electric power systems have been on the market for a decade, and their complexity increases every year. These systems are more powerful and require more information from different systems to add new levels of safety, steering feel and driver convenience.

The modern electric power steering module communicates with at least the ABS and engine control module on a high-speed CAN bus. The power steering module can also look at other information through a gateway module.

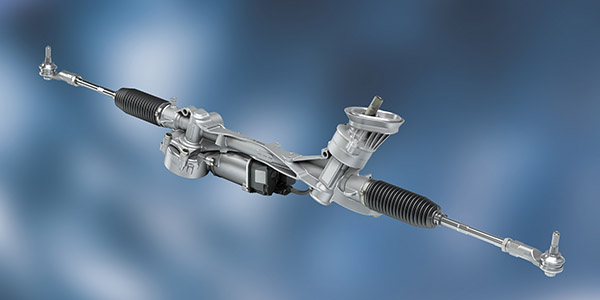

The most advanced electric steering application uses a bi-directional brushless motor, sensors and electronic controller to provide steering assist. The motor will drive a gear that can be connected to the steering column shaft or the steering rack.

Like older systems, sensors located in the steering column measure two primary driver inputs — torque (steering effort) and steering wheel speed and position. The controller processes the steering effort and hand wheel position through a series of algorithms for assist and returns to produce the proper amount of polarity and current to the motor.

What sets more advanced systems apart from previous systems is the resolution of the torque and steering position sensors. The sensors can measure smaller changes in the driver inputs.

There are three different types of electronic torque sensors, and they are classified as contact and non-contact types. A non-contact sensor uses a magnetic rotor with alternating pole pieces and is attached to the torsion bar. Hall-type sensors monitor the twist of the torsion bar by measuring the change in magnetic flux generated by its position to the vanes located on the sensor stator rings.

When the rotor moves, a change in magnetic flux will produce a signal to an analog-sensing integrated circuit that will process the signal and send the information to the controller’s assist algorithm.

With more accurate data and faster modules, the electric motor is now doing a lot more than just assisting the driver. With just a few more sensors and new software, the car of the future is being made possible by electric power steering.

Can’t parallel park? Mount some proximity sensors in the bumpers that can be used for a parking assist system that can parallel park a vehicle. All the driver has to do is operate the gas and brake.

Add front and rear cameras and proximity sensors to the side-view mirrors and you have a lane departure system that can tell when the vehicle is drifting out of its lane. Video game-style feedback systems can shake the wheel like they are hitting an imaginary rumble strip; more aggressive systems can take action and steer the vehicle back into the lane.

These systems have software that can determine if a lane drift is due to a distraction like a phone call or a legitimate, intended lane change. NHTSA is looking at mandating these systems on new vehicles soon.

Combining adaptive cruise and electric power steering can almost create the self-driving car, and some automakers are taking this first step at slow speeds. Audi, Mercedes-Benz and Volvo are introducing a feature that allows the driver to be completely hands-off during a traffic jam. The driver can sit and relax while the system takes over.

With more information and sensors, diagnostics have been made easier compared to older systems. The right scan tool can look at many data PIDs and engage in bi-directional tests. A scan tool is also essential for calibrating sensors and reflashing replacement modules.

THE FUTURE

The future of electric power steering is bright as vehicle manufacturers look to improve fuel economy and add features that can set their vehicles apart from the competition. The other area electric power steering can help with is stability control.

New steering systems work with the ABS/ESC systems to make small corrections to the steering to keep the vehicle pointed straight. These types of conditions can occur if a vehicle is braking on surfaces with uneven levels of traction.

The BMW system, for example, will make tiny corrections to the wheel angle (typically not noticed by the driver) to make the correction with the ABS modulator more effective. These system integrations would not be possible if the yaw and steering angle sensors were not accurate.

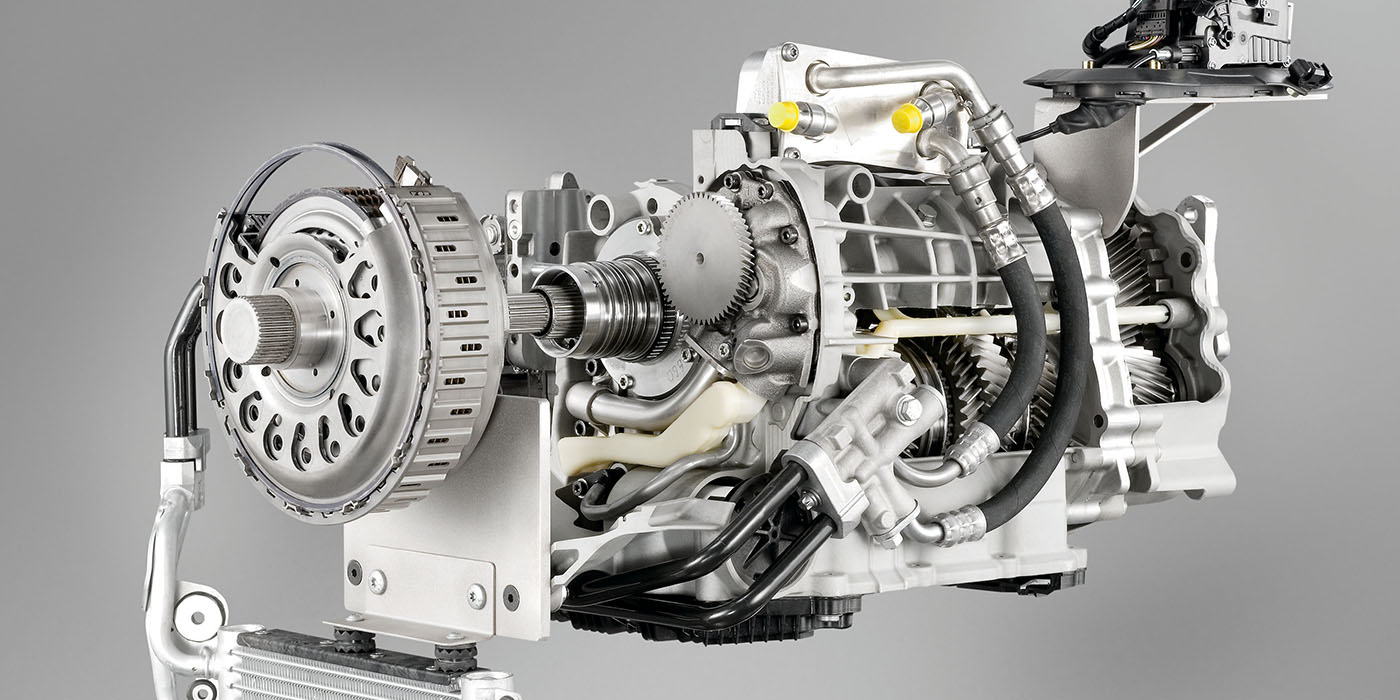

Adaptive or active steering changes the ratio between the driver’s actions at the steering wheel and at the rack. In traditional vehicles, this is a fixed steering ratio. With this new technology, the steering ratio continually changes with vehicle speed, optimizing the steering response in all conditions.

At lower speeds, such as when pulling into a parking space or maneuvering in tight quarters, the system makes the vehicle more agile and easier to turn as it dials more steering into the road wheel. Each low-speed maneuver requires less turning of the steering wheel.

At highway speeds, the system further optimizes steering response, enabling the vehicle to react more smoothly and precisely to driver input. Adaptive steering can help the driver feel more comfortable and can make any drive more enjoyable.

BMW’s system puts an electronically controlled planetary gear between the rack and motor. The system can be locked if a problem is detected. Audi and Lexus place a gear reduction box between the steering wheel and rack with a locking mechanism included as a fail-safe.

Servicing these systems will require training and enhanced scan tools, and diagnosing these systems will also require an advance understanding of CAN buses.

But the most important step you can take today is to start a program at your shop to address the calibration of steering position sensors after steering system service or an alignment.