Shop profitability is always a hot topic in the automotive service business. As a point of comparison for most shops, brakes, steering and suspension services usually top the list in profitability, while engine repairs rank somewhere near the bottom. The key to profitability is to establish a benchmark on how many dollars can be earned per hour.

Since front brakes wear out first, let’s use a front brake replacement on a 2003 Honda Accord (see photo 1) to illustrate the point. In contrast to engine repairs, replacing the Accord’s front brake pads requires only basic hand tools. Better still, my labor guide rates the skill level in the “B” range.

THE TIME FACTOR

To keep the math simple, I’m basing my labor times on component replacement only and rounding off prices to the nearest dollar. One popular aftermarket labor guide lists the 2003 Accord’s front brake component replacement times as follows: A basic pad replacement is 0.9 hours. The removal and replacement (R&R) of both rotors is 0.8 hours. Total time for replacing front pads and two rotors = 1.7 hours (see Photo 2).

To illustrate the math, let’s use a typical “B” labor rate of $80/hour. At 1.7 hours times $80, the brake pad and rotor replacement bills at $136. (If a skilled technician completes the pad and rotor replacement in one hour, the effective labor rate increases to $136 per clock hour.) Replacing both hydraulic hoses will add 0.2/hour ($16) for the pair. If we add 0.5 hours ($40) for bleeding and flushing the brake hydraulics, the gross profit on a total labor time of 2.4 hours is $192.

If you’re wondering why I wouldn’t resurface the brake rotors, let’s begin by saying that a typical hat rotor doesn’t have much machinable stock to begin with, let alone 60,000 miles later. If the rotors don’t clean up, it’s very easy to waste 0.8 hours of book time attempting to resurface the pair. When labor costs are balanced against parts costs, installing new rotors is the more economical and reliable option. The same can be said for rebuilding brake calipers when new pistons are required to finish the job (see Photo 3).

THE PARTS FACTOR

To illustrate an hourly parts profit in rounded numbers, let’s begin with a set of premium aftermarket pads at a wholesale cost of $47. To keep the math simple, let’s apply a 1.66 mark-up ratio, which is equal to a typical 40% profit margin. A cost of $47 times 1.66 = $78 retail for the pads, leaving a gross profit of $31. Wholesale prices for rotors vary considerably, so let’s pretend that we can buy some aftermarket rotors for $60 per pair. Using a 1.66 markup ratio, the retail price for two rotors will be $100, leaving a gross profit of $40. The gross profit on pads and rotors is $71 (see Photo 4).

ADD-ON SALES

A weathered brake caliper boot or sticking caliper piston will condemn the caliper. To prevent brake pulling complaints, I recommend replacing calipers in pairs. In rounded numbers, at $54 wholesale per pair, we’re marking up a pair of calipers by our factor of 1.66 — which = $90 retail, leaving a $36 profit.

If we find weathered or damaged brake hoses, let’s buy a popular brand at $24 per pair wholesale. Applying our 1.66 markup, the pair of hoses retails at $40, leaving a profit of $16. When the total profit of $36 for calipers and $14 for hoses is added to the $71 profit from pads and rotors, the gross profit on parts is $121 (see Photo 5).

RISK VERSUS LIABILITY

When we compare the risks and liabilities of engine repairs with those of brake repairs, brakes are by far the more profitable repair. While big-ticket engine repairs usually amount to thousands of dollars, they tend to produce fewer dollars per hour in profit.

When labor profit ($192) is added to parts profit ($121) for a front pad and rotor replacement, the gross profit for the complete job = $184 per book hour. In the real world, an experienced technician would likely replace the front brake pads and rotors on our 2003 Honda Accord in a little over an hour.

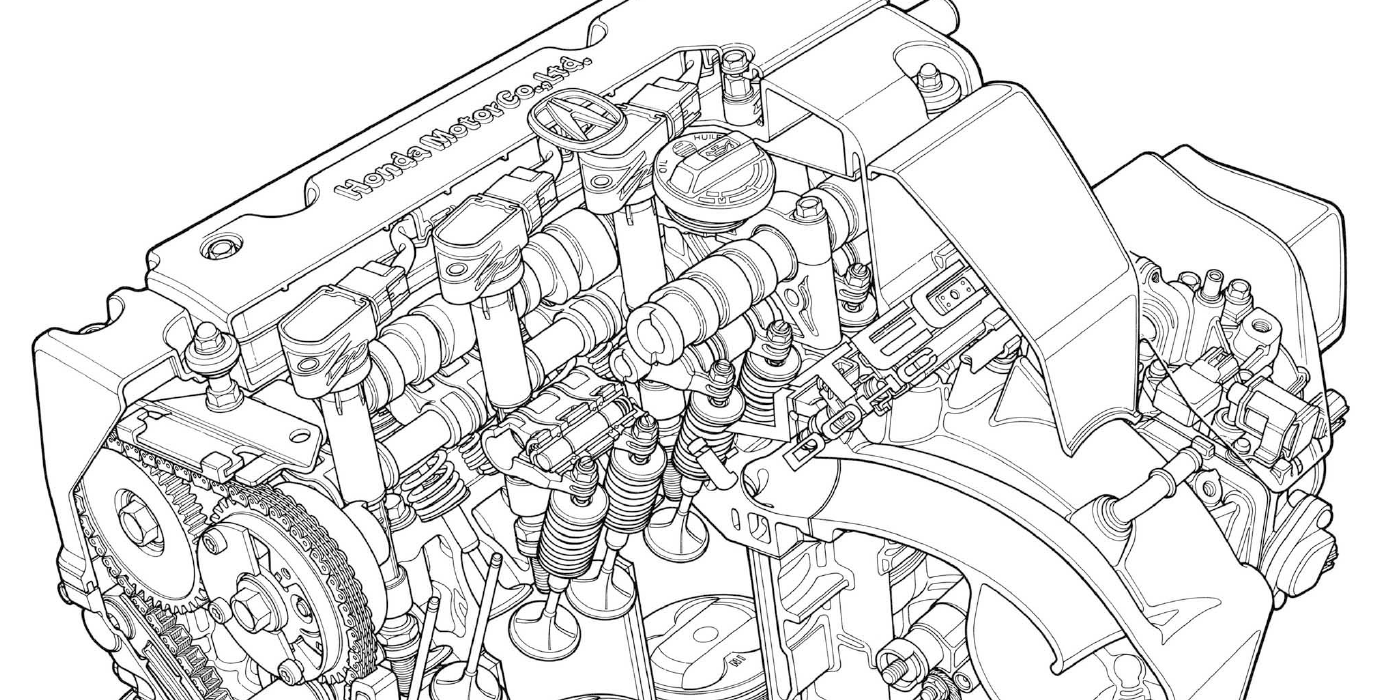

In contrast, a timing chain replacement on our 2003 Honda Accord equipped with the 2.4 L 4-cylinder engine requires about 5.0 hours of labor time, plus a minimum cost of about $150 in parts. At a “B” skill level rate of $80/hour, 5.0 hours = $400 total labor. At a 1.66 markup, $150 in parts = $250 retail, leaving a gross profit of $100. Adding the $400 labor to the $100 parts profit, the engine repair produces $100 per hour of gross profit.

When risk and liability are factored into dollars per hour profit, brakes are the hands-down winner. Brake installation is nearly foolproof, providing all parts surfaces are cleaned and correctly lubricated, and all of the caliper mounting bolts and wheel lug nuts are tightened to specification. While a higher skill level is occasionally required to install some brake hardware, it’s really hard to ruin a brake replacement. Since most customer complaints can be remedied well within our original 1.7 hours of replacement time, the risk and liability factor is very low.

When a timing chain is replaced, the technician must time the camshafts perfectly. If he misses a timing mark, the job must be re-done. If the engine leaks oil after the repair, the timing cover gasket or front crankshaft seal must be re-done, which can add up to four unpaid hours to the repair.

And, then, we get into what I call the “imponderables.” Maybe the engine was run out of oil, which is the root cause of the timing chain failure. Or, maybe the timing chain was replaced in Omaha, NE, and the engine failed the following week in Topeka, KS. Who’s to blame? I don’t know, but you get the picture. Engine repairs are usually high-risk, high-liability services. Despite the timing chain repair being listed in the “B” skill level, you might want to put your best technician on the job, instead of the trade school graduate you hired last week. And, you might want to raise your hourly labor rate on internal engine repairs to compensate for the higher risk and lower reward.

TOTAL BRAKE SERVICE

As illustrated above, we have a lot of latitude in how we package and price brake services. Menu pricing is always an option, but don’t sell your shop short on profit. If you’re a nameplate specialty shop, it’s relatively easy to spot pattern failures on related parts like wheel bearings, axle halfshafts, ABS sensors, ride control parts and steering linkage.

It’s also much easier to track recalls and TSBs for a particular vehicle line. And, speaking about lines, an auto repair business should be all about “bottom” line. The more brake services you perform, the better the bottom line will be.