Q. Should I machine new brake rotors?

A. Yes and No. High-quality replacement rotors typically are made to very tight tolerances for lateral runout. But, the tolerances during manufacturing are measured on precision equipment that lives on the manufacturing floor. Rotors operate in an environment between the wheel bearing flanges and wheels where tolerances can stack up.

A new rotor may have 0.001˝ of runout at the factory, well within runout specification for most new vehicles. But, when it is installed on a flange that has 0.003˝ of runout, and throw in a little corrosion, the assembly could be above 0.004˝ of runout and well beyond most OEM specifications.

What is a shop to do? Find a perfect 0.0000˝ rotor? Replace the wheel bearing and flange? There are options and it might involve machining a new rotor.

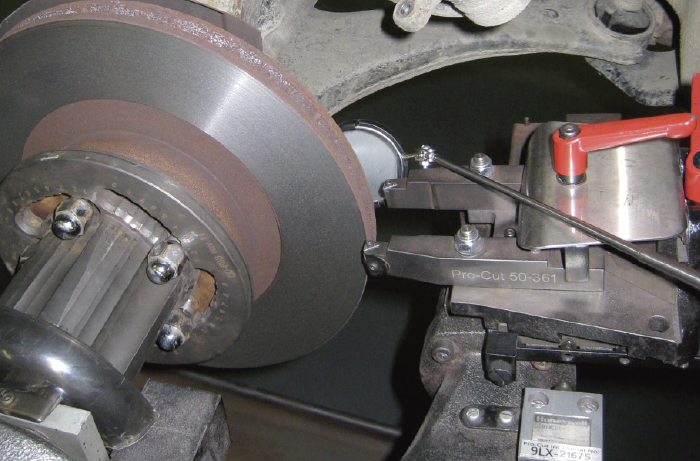

The cure for lateral runout is an on-the-car brake lathe. This type of lathe can cut the rotor to the runout in the flange so there is zero lateral runout in the total assembly. Other options include indexing the rotor to the flange to cancel out or minimize runout or tapered shims that fit between the flange and rotor to correct runout.

Q. What causes a rotor to crack?

A. Rotors do not crack from hitting a pothole or curb, but due to the stress of heat and cycling from hot to cold. Mechanical stresses from stopping the vehicle can also play a part.

Every time the brakes are applied, the rotor heats and expands. After the calipers release, the rotor cools and contracts. This can create fatigue in a rotor that can cause cracking and structural failure.

A replacement rotor that has been engineered and manufactured has built-in features to manage the stress of the heat cycles. It first starts with the design of the fins and hat structure. The most critical area of the rotor is where the rotor’s plates connect to the hat. Some rotors will have special heat dams to control the different rates of expansion of the rotor and hat. Next, how the rotor is manufactured can prevent cracks. The heat and energy of the casting process and how the rotor is cooled before it is machined can cause or reduce stress in the rotor.

Q. Are there any safety certifications or requirements for replacement rotors?

A. Nope. A replacement brake rotor or pad does not have to be tested to any specification by the government in the U.S. For new vehicles, the DOT tests the brakes as part of an assembled vehicle under specific conditions. The vehicle must be able to stop below a specified distance under different loads, scenarios and pedal pressures.

Brake rotor manufacturers must engineer their rotors to operate at the same level or better as the OEM rotor. Deviating from the OE design to save money can result in a compromised brake system.

That being said, the Society of Automotive Engineers (SAE) has developed a series of tests on a brake dynamometer to test replacement brake rotors for resistance to cracking.

SAE J2928 test procedures subject a rotor to 150 heat cycles, where the rotor is cold and brought to a high temperature. During a heat cycle, a rotor will expand and contract. This can create fatigue in a rotor that can cause cracking and structural failure.

During the 150 heat cycles, the rotor is inspected; this includes dimensions and an inspection for damage. The objective of the test is to thermally and mechanically stress the rotor so any deficiencies in the metallurgy or structure are exposed. J2928 also covers how to document and classify cracks.

Unlike a USDA grade or a movie rating, SAE J2928 is just a document and recommended procedures. It is up to the industry to adopt and embrace these tests.

Q. Can corrosion compromise the structure of the rotor?

A. No. It would take a lot of corrosion in the right areas to cause a structural failure of the rotor. Wear from normal braking past the discard specification has a greater chance of destroying the rotor.