What’s Holding You Back?

There are some myths about brake pads, rotors and hydraulics that need to be busted. On the surface, some of these myths make sense. The logic might even seem profound, but, ultimately, they do not help resolve real brake system issues. These myths can hurt a technician’s ability to effectively diagnose and solve common brake problems as well as customer concerns.

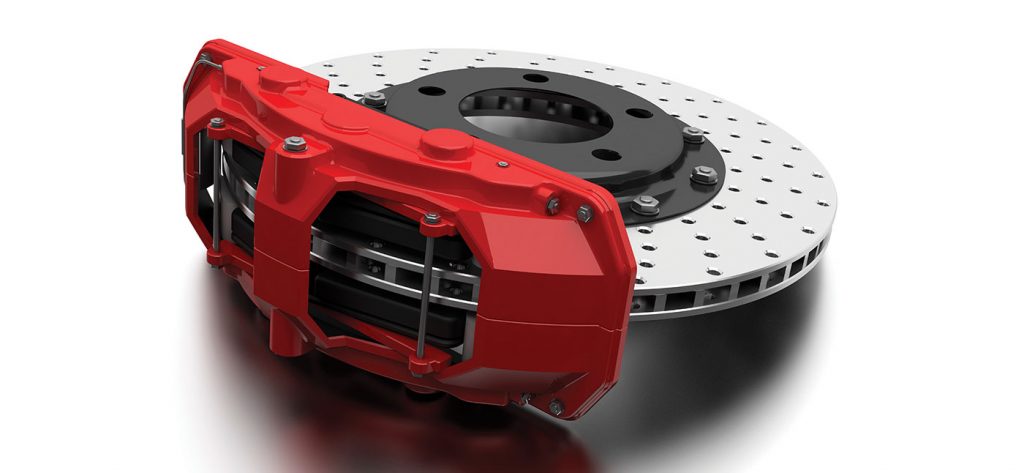

A Rotor’s Minimum Thickness Specifications Are Based On Heat

False: No matter if it is an Audi or a Subaru, the original and even replacement rotors have a minimum thickness specification cast, machined or etched somewhere on the rotor. You might think that this dimension is based on the “thermal capacity” of the rotor. But, this dimension is more hydraulic than thermal.

The discard or minimum thickness specification is based on the travel of the caliper piston if the pads are worn to the backing plates. If you had worn pads and a rotor that’s below specification, there is a possibility the piston could start leaking and become dislodged from the bore, causing a failure of the brake system. Heat, warping and fading have nothing to do with discard specifications.

Soft/Hard Pads = Soft/Hard Pedals

Mostly False: Compressibility can influence pedal feel, but only in extreme cases where the pad is defective. What really influences pedal feel is the coefficient of friction on the brake pad. If a pad has a low coefficient of friction, it can cause a long brake pedal because the driver has to push harder on the brake pedal. If the brake pad has a high coefficient of friction, it could cause a high pedal that requires less force to stop the vehicle.

The coefficient of friction can change as the temperature of the rotor and pad increases. High-quality friction materials have a stable friction level for cold and hot temperatures.

Wet Brake Rotors Increase Stopping Distances

True and False: Remember when you were first learning to drive and some adult told you to tap the brake pedal after you drove through a puddle? In the days of drum brakes, this was good advice, but with disc brakes, this piece of advice does not hold water, literally.

If a vehicle is moving, water is thrown off the face of the rotor by centrifugal force. Any water on the pads is inconsequential. But, some vehicles like Mercedes-Benz will auto-pulse the brakes to remove water if the rain-sensing wiper system detects water on the windshield.

Replacement Brake Pads Are Regulated For Performance

False: There are no government-mandated or industry regulations regarding brake pad performance. In Europe, there are regulations for replacement brake pads called R90. This standard is performed on a vehicle.

Brake Pads Need To Warm Up

False: Street brake pads are designed to produce brake torque even at very low temperatures. This is also true for exotic carbon-ceramic brake systems on street-driven vehicles.

The exception to this myth is with high-performance racing pads that require some heat in the friction material to generate the highest coefficient of friction. Manufacturers of these pads will say that they should only be used for off-highway purposes. These friction material typically have an edge code that ends in ZZ.

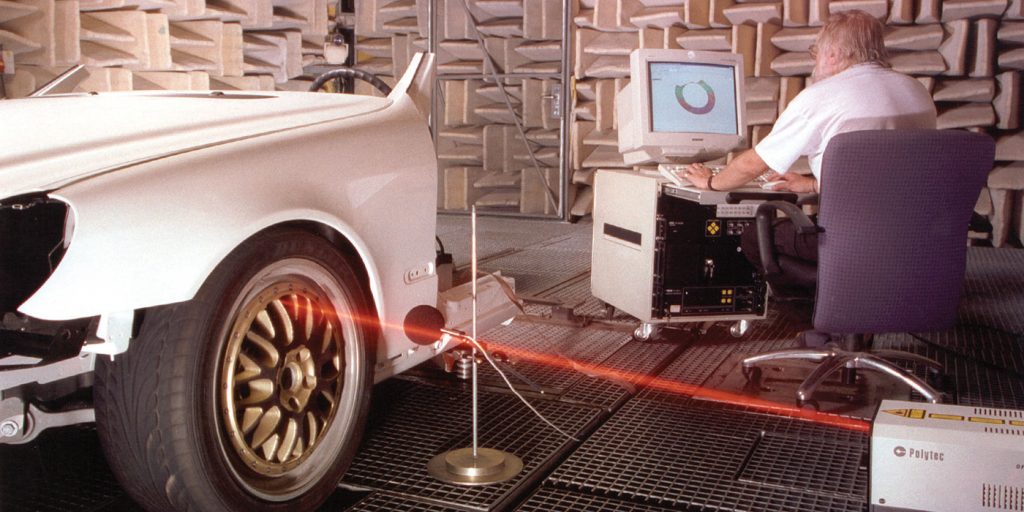

Brake Pads Are The Source Of All Brake Noise

True and False: All brake pads do produce vibrations when they are applied. But, it is “how” the vibrations are transferred to the rest of the vehicle that causes a driver to hear or not hear the noise. A brake pad is merely the string on a guitar; it is up to the player (or vehicle in this analogy) to decide how it sounds. Reducing the mass of the brake rotor can even change brake noise.

A “consistent” friction material causes less vibrational excitation variation at the friction coupling by having consistent brake torque at environmental extremes of humidity and temperature (-40° F to 500° F).

Typically, high-frequency noises come from the caliper, rotor or bracket. Low-frequency noises, like growls, grunts and moans, can be caused by struts, knuckles or even the body structure.

The option for technicians is to isolate the pads with lubricants or shims and to restore the hardware to like-new condition.

Rotors Warp

False: Rotors do not warp. In the 1970s, someone came up with the whole “warping” theory and it has stuck. Why? Because to the layman, it makes sense. But, in reality, it is a false explanation that doesn’t hold up. What is often described as “warping” is actually the presence of two verifiable phenomena that can be experienced individually or in combination — neither of which has anything to do with warping. These phenomena are brake torque variation (BTV) and disc thickness variation (DTV).

BTV is a variation of torque across the face of the rotor that causes the rotor to slip and catch as brake pads pinch the rotor. The differences in torque across the rotor may be caused by an inconsistent rotor finish or the metallurgy of the rotor.

BTV can be caused by uneven deposits of friction material. This might not cause a pulsation in the pedal, but it will cause the vehicle to judder or vibrate.

DTV, on the other hand, is the result of measuring the thickness of the rotor surface at multiple spots around the rotor. Subtract the thickest part from the thinnest, and you will have a measurement for DTV.

As the thickness variations of the rotor pass through the caliper, the piston moves in and out. This action generates pulsations in the brake pedal that can be felt by the driver.

More Lube Means Less Noise

False: Basting a set of pads or caliper slides in lubricant, no matter how expensive, will not solve a noise issue for an extended period of time. Why? Because the excess lubricant can melt, causing some chemicals to flash off. The melting lubricant can find its way onto the pads, causing a judder problem and longer stopping distances.

Excessive lube can also attract debris and dirt. As the lube hardens over time, it turns to a concrete-like substance that causes slides and calipers to stick. If excessive lubricant finds its way onto the caliper piston’s boot, the lubricant will attract metal particles that can destroy the rubber.

Shims need only a small amount of lubricant. Some floating one- and two-piece shims require only a small amount of lubricant between the surfaces of the shim and pad. There is no need to coat the entire back of a brake pad with a lubricant.

Use a silicone-based brake grease for the caliper anchor pins. Make sure it is compatible with all rubber compounds including nitrile, Teflon, nylon and other synthetic rubbers. For the shims, abutment clips and slides, use a synthetic-based boundary-type lubricant that has a high solids content and typically contains a variety of friction-reducing ingredients, such as molybdenum disulfide (moly or MOS2) and graphite.

All Pads Are The Same

False: One of the greatest myths out there is that some customers will not use the full potential of a brake pad due to their driving style or commute. This is false because the one time that the customer needs to use the full potential of the pad, the performance will not be measured in dollars and cents, but rather in inches and feet.

What standards should you have when selecting replacement brake pads? Try them for yourself! Set aside some time when the shop is not busy or on a weekend to try out the brands of brake pads you install. Perform at least four emergency stops from 55 mph to a dead stop, back to back. Let your right foot be the judge.

All Rotors Are The Same

False: Even if a rotor fits on a vehicle, it may still not be the right rotor for the vehicle or driver. Low-quality rotors may have compromises in their structure and metallurgy that may make sense to the wallet, but not the driver or performance of the rotor. Do some shopping around to find the right fit.

New Rotors Need To Be Machined

True and False: New rotors are supposed to be finished to specifications and ready to install out of the box. There should be no reason to give them a “clean up” cut. If they do need a cut, you need to find a different rotor supplier. Machining new rotors shortens rotor life. It may also leave a rougher finish on the rotors than the factory finish.

The manufacturing tolerances for rotor runout on most new rotors average about 0.001 inches or less, with a maximum upper limit of 0.004 inches. Some vehicles are unusually sensitive to rotor runout, such that as little as 0.0015 inches of runout may produce noticeable pedal pulsations.

But, if the new rotor has excessive runout when it is installed, an on-the-car brake lathe can correct the runout in the flange and rotor.

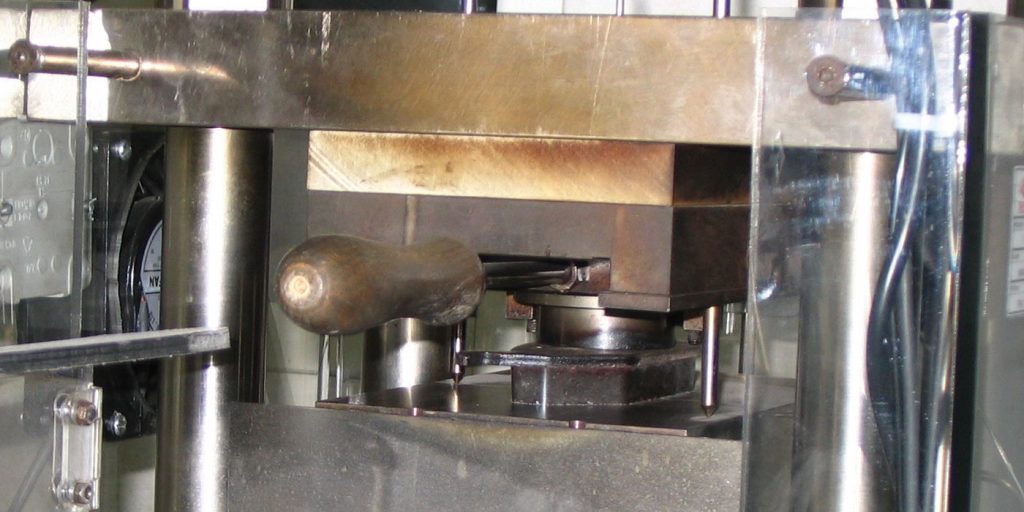

Dial Indicators And Micrometers Are Not Necessary

False: Some shops assume that measuring rotors can be done with the naked eye and that quality measurement tools either do not exist or are not affordable. This myth is not true. If your shop does not have a dial gauge and a set of micrometers to measure rotor thickness, you should not be performing brake pad or rotor replacements for your customers.