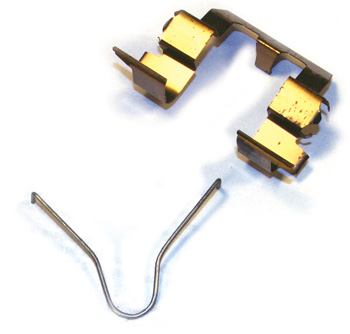

Every technician has struggled with those little wire clips that push the pads onto the pistons on some Mazdas and Fords. Those little clips that barely fit into the painted-over holes on the new pads and can shoot across the shop like a rubber band can make a big difference.

Every technician has struggled with those little wire clips that push the pads onto the pistons on some Mazdas and Fords. Those little clips that barely fit into the painted-over holes on the new pads and can shoot across the shop like a rubber band can make a big difference.

One racecar builder who specializes in building “showroom stock” vehicles found out just how important this small piece of brake hardware can be. This builder commonly discarded those little wire clips thinking that they did not provide any advantage in a racing environment.

While between runs on a chassis dyno, he realized that the front brakes of a vehicle needed new pads. Not having time to do the job himself, he had one of his employees perform the job. This time, the tech replaced the missing hardware including the wire clips that pushed the pads against the piston. On the baseline run, the car gained a very small amount of horsepower at the wheels.

The idea of gaining horsepower by replacing the brake hardware seemed impossible. But after he performed further runs with and without the clips, he realized that the little clips reduced brake drag. On a street vehicle, it could mean better fuel economy.

The idea of gaining horsepower by replacing the brake hardware seemed impossible. But after he performed further runs with and without the clips, he realized that the little clips reduced brake drag. On a street vehicle, it could mean better fuel economy.

The discovery meant more power at the track, and on the street it could mean a brake job that could last longer.

Hardware is for more than drums. Replacing disc brake hardware is critical to returning the system back to its original condition.

Brake hardware for disc brakes is not a dealer-only item. Your local jobber might carry three lines of hardware. This product category is more than shims, anti-rattle clips or dust shields. Many of these lines of products include items like caliper brackets, slides and all the soft parts to restore the system to like-new condition. Many of these parts are at reasonable prices that you and your customer cannot refuse.

Remember, no amount of lubricant can make up for weak, missing or rusted brake hardware.

SPRINGS AND CLIPS

Heating and cooling cycles can weaken springs and anti-rattle clips. Weak hardware parts can result in excessive caliper/pad movement or binding causing noise and other related problems. This can lead to uneven and premature pad wear, rotor warpage and pulling.

Some springs and clips can be difficult to install. Some anti-rattle clips may resemble Chinese finger traps when you are trying to reinstall them back on the car. But leaving them out is not an option.

Some springs and clips can be difficult to install. Some anti-rattle clips may resemble Chinese finger traps when you are trying to reinstall them back on the car. But leaving them out is not an option.

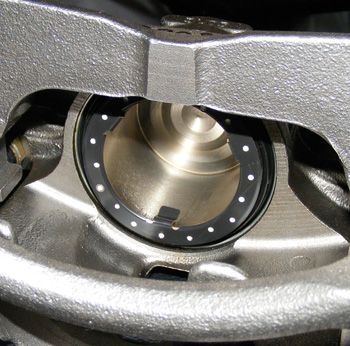

When rust and corrosion build up on a floating caliper’s slides or bushings, it can prevent the caliper from centering itself over the rotor when the brakes are applied. Not only does this reduce effective braking force and increase the vehicle’s stopping distance, it also causes uneven pad wear.

The same condition may also create uneven braking between the right and left calipers, causing the brakes to pull toward the stronger side.

SOFT PARTS

When technicians think of brake hardware, they think springs, clips and slides. But soft parts like dustshields, grommets and bushings need just as much attention.

Most floating brake calipers use a rubber or plastic insulator or shim around the mounting bolts of the caliper. This sleeve of soft material loses resiliency over its lifetime. This is hastened by the high-temperature environment of the brakes. As materials wear, instead of being round they are flattened by the torque from the brakes into an oval shape that can cause excessive caliper movement. This can cause noise like rattles and thumps even if the brakes are not applied.

Always inspect and replace if necessary any dust boots or grommets that protect caliper bolts or slides. If the soft parts look OK, clean out all the old lubricant and replace with new lubricant.

Unlike steel, soft parts like rubber are sensitive to chemicals. Choosing the right lubricant for these parts is critical to ensuring the integrity of the part.

There are three criteria to remember when selecting a brake lubricant. First, does it say that it’s a brake lubricant on the package? If not, do not use it. Some lubricants may say they are a silicone or molybdenum disulfide based, but they may not be formulated to work on brakes. Second, look at the effective temperature range of the lubricant. At minimum, a lubricant should be able to handle 400° F. Third, check to see if it contains petroleum distillates or any substance that can be detrimental to soft parts.

SHIMS

Insulating the brake pad from the caliper can be done two ways.

The first option is to go the “chemical” route with sprays or paste coatings. This type of noise solution involves coating the back of the pad prior to installation. The coating serves as a layer between the pad and caliper. If your shop uses any of these products, make sure to follow all manufacturer directions on where to apply and what the curing times are. Not following the directions can mean a comeback.

The first option is to go the “chemical” route with sprays or paste coatings. This type of noise solution involves coating the back of the pad prior to installation. The coating serves as a layer between the pad and caliper. If your shop uses any of these products, make sure to follow all manufacturer directions on where to apply and what the curing times are. Not following the directions can mean a comeback.

The second solution is a physical shim that is a sandwich of materials that is staked to the back of the pad. One drawback to shims is “shim migration” or shifting that can negate its insulating abilities. But, automakers and aftermarket parts suppliers are developing an attachment system to alleviate this problem.

The second solution is a physical shim that is a sandwich of materials that is staked to the back of the pad. One drawback to shims is “shim migration” or shifting that can negate its insulating abilities. But, automakers and aftermarket parts suppliers are developing an attachment system to alleviate this problem.

Some automakers stamp notches and posts that index and stake the shim on the pad. Certain manufacturers of shims use pressure-sensitive adhesives to secure the shim to the backing plate. But over time, moisture and heat can destroy the adhesive. One new design to secure the shim to pads are clips that clamp on to the sides of the backing plate. These clips reduce the tendency of the shim to shift or fall out during the life of the brake linings.

But remember, a shim does not do its job if it is left in the box.

But remember, a shim does not do its job if it is left in the box.