When I started with Brake & Front End, there were two prominent friction material families – semi-metallics and non-asbestos organics. Semi-metallics were known for being more aggressive or suited for applications with heavier loads and braking forces. Non-asbestos organics were for lighter passenger vehicles where noise and longevity were the top concerns.

About 20 years ago, a new family of friction materials was being offered on passenger vehicles. The new category of ceramic friction materials was part science and part marketing. Technically, a ceramic could be classified as a non-asbestos organic friction material when it was first introduced. The promises of low noise and brake dust had a lot of people listening to the marketing messages.

Ceramic materials that go into a brake pad are tiny strands engineered to be a certain length and width. Some of the early articles on ceramic say the fibers were a replacement for asbestos fibers. But, these synthetic ceramics fibers also increased the performance of the friction materials.

There are three advantages of ceramic friction material in specific applications. First, ceramic materials offer stable performance under a wide range of temperatures. This friction stability provides both performance and noise advantages. By having a consistent coefficient of friction over a broad range of conditions, the engineers can match the caliper, rotor and attached components. Second, ceramic brake pads manage heat in the caliper better on some vehicles than some non-ceramic applications. Third, ceramic brake dust does not show up on or stick to wheels like other brake pad formulations. This is because the brake dust from a ceramic material has a different electrical charge that makes it less likely to stick to wheels.

When the first ceramic replacement brake pad lines came out 25 years ago, the pads were marketed as a noise solution for all vehicles. But, that is where some lines ran into trouble by selling ceramic materials for all vehicles. On some applications, the ceramic pads were having issues with pedal pulsation and judder. Some blamed the high-temperature ceramics for warping rotors. But, most engineers knew the problem was runout and something called a “transfer layer.”

Ceramic friction material uses adhesive or adherent friction properties. This type of friction works best if the friction material creates friction against itself. These types of pad material transfer a very thin layer of pad material onto the surface of the rotor. The transfer layer is bonded to the rotor’s surface and cannot be washed away by water or wheel cleaners.

When the brakes are applied, the transfer layer is broken down and replenished on the rotor. Adherent friction is easier on rotors, but the pads become the primary wear component. This is also one of the disadvantages of a ceramic friction material. If the rotor has excessive lateral runout or poor surface finish, the transfer layer could be laid down unevenly. An inconsistent transfer layer can lead to brake pedal pulsation and brake judder.

Twenty years ago, some ceramic brake pad lines got a bad reputation for pedal pulsation. The issue was not the friction material, but the reconditioning of the rotor. Often, the rotor was not refinished properly, and the transfer layer was not consistent across the entire surface of the rotor. Also, just replacing the pads often lead to the contamination of the new ceramic brake pads due to incompatibility of the transfer layer material.

Semi-Metallics

In the first part of the 20th century, friction materials were woven with asbestos fibers. The materials were sold in rolls and trimmed to fit drum brake shoes. As material engineers improved resins, they could ditch the woven materials and make a better brake material called a semi-metallic. These materials still had asbestos content, but the ability to mold and bond a friction material to a shoe or backing plate had a definite advantage.

Semi-metallic pads first use metal fibers to give structure and provide friction. The metals used are typically high-quality steel, copper and other exotic metals. The other part of the semi-metallic mix consists of a variety of materials like glues, lubricants and structural fibers like Kevlar. The manufacturer will blend the components to provide the best performance for that application.

Semi-metallic friction materials are still used by OEM and aftermarket manufacturers because they can produce predictable levels of hot and cold torque.

NAO

Non-asbestos organic (NAO) friction materials typically wear more than harder semi-metallic compounds. Generalizing the wear characteristics of NAO and ceramic-based compounds is difficult because there are so many variations depending on the manufacturer. Wear varies depending on the formula the friction supplier chooses for a particular application. Different vehicles require different coefficients of friction, so recipes are often “application engineered” to deliver the best combination of stopping power, wear resistance, pedal feel and noise control. Most premium-quality NAO and ceramic-based linings will provide long life and wear less than an equivalent set of NAO pads on the same application.

Application-Specific

When a new vehicle or platform is introduced, the friction material and brake pad design will likely be specific to the application. It could be a ceramic, semi-met, or something in between. The OEM and supplier work together to achieve the best pedal feel, performance and NVH.

Aftermarket brake pad suppliers are taking the same approach to their premium friction lines. Instead of classifying the line as a ceramic or semi-met, they sell it as a match to the original friction material.

THE UNSEEN ASPECTS

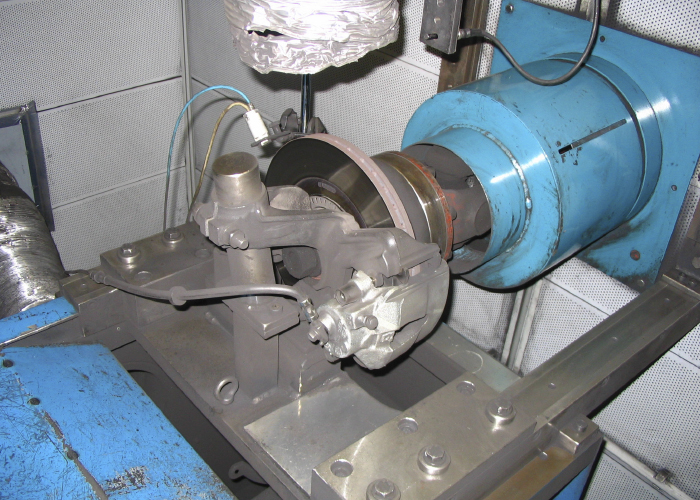

When you are buying a brake pad, you are also buying the engineering and research behind it. When an aftermarket brake pad manufacturer is developing or reverse-engineering an application, they rarely test on an actual vehicle. This type of testing is expensive and time-consuming. A brake dynamometer can test brake systems in a controlled environment that mirrors the real world. A brake dynamometer can run 24 hours a day and measure the performance of a braking system over its entire lifetime. Plus, would you want to be a brake pad guinea pig for 25,000 miles?

A brake dynamometer can be more sophisticated and larger than an engine dynamometer. Brake dynamometers can simulate the conditions the brake system will experience in a much shorter time. This means that a brake dynamometer can simulate the mass, inertia and performance capabilities of a vehicle.

The typical brake dynamometer can cost anywhere between $250,000 (used) to more than $1 million. Some brake friction suppliers own dynamometers, while some lease dynamometers from testing companies.

In the engineering world, there is a saying that goes: “One test is worth a thousand expert opinions.” This saying is also true for the brake technician.

Knowing that the company you are buying friction products from has made the investment to carry out brake dynamometer testing can mean an extra measure of confidence.

Picking the correct brake pad for a customer’s vehicle might require some research and, unfortunately, some trial and error. The best advice for any shop is to try a set of brake pads on your own vehicles. This way, you will know if the pads live up to their promises.