Some ADAS systems are now more than 10 years old. For the 2008 model year, the BMW 5 and 6 Series (E60, E61, E63 and E64) received a lane departure system, which alerts the driver by shaking the steering wheel.

The system uses a camera to view the road ahead, and a module behind the glove box processes the images and data from multiple modules to decide if the driver is straying from the lane. The system uses road markings to determine the vehicle’s placement in the lane.

The Camera

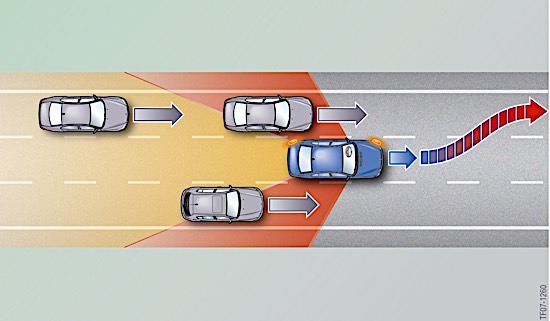

The camera’s scope of detection ranges from approximately 4 to 40 meters ahead of the vehicle. The camera has a horizontal aperture angle of approximately 50°, and a vertical aperture angle of approximately 30°.

During operation of the wipe/wash system, the sweep of the wiper blades also takes them through the field of view of the lane departure warning’s camera.

The Lane Departure Control Module

The lane departure warning control unit receives several input signals. The image data of the camera is evaluated in the control unit together with the other vehicle data that the control unit receives on the PT-CAN. The lane departure warning is determined from the combination of this data. The body gateway module transfers the PT-CAN messages from the lane departure warning control unit to the K-CAN. The control unit receives vehicle data on the PT-CAN.

The control unit for the lane departure warning system is awakened by the wake-up signal of the control units on the PT-CAN. The Car Access System control unit controls the wake-up line, as well as the waking of the control unit for the lane departure warning. In sleep mode, the control unit is switched off.

When the ignition is switched on, the lane departure warning system always reverts to the state that was active when the vehicle was last switched off (last function mode).

Calibration

If the system is to be able to calculate the distance to a given roadway marking, it must know the exact installation position of the camera and the camera’s exact focal direction on the other. Due to installation tolerances and tolerances inside the camera, the position of the camera’s viewing angle may vary by several degrees. The exact installation position of the camera and its installation angle are determined during the calibration of the system and stored in the system.

Any replacement of the camera or windscreen requires a calibration of the system because the position of the camera and the system sensor may have changed. No calibration is required if the control unit is replaced. In this case, the calibration data stored in the camera is transferred to the control unit and stored there.

Each time the system is started, a check takes place to determine whether the system is calibrated and whether the system components are matched to each other and the vehicle. With this plausibility check, it can be determined whether the control unit is coded correctly and whether it belongs to the vehicle.

The VIN stored in the camera is then compared with the VIN stored in the control unit. If discrepancies are detected, the system detects that a camera requiring new calibration has been fitted and it outputs a corresponding fault codes.

Calibration takes place during a calibration run, which can be carried out by the customer. In the event that the camera test failed, the calibration process is terminated and must be restarted after the possible interfering factors have been remedied.

The calibration algorithm works from a speed of 19 mph. It uses images captured during straight-ahead travel. As soon as enough information has been recorded, the viewing angle is calculated and stored in the control unit. This process generally takes a few minutes. In conditions of poor visibility like night, rain or winding roads, the calibration process may take up to 20 minutes.

The calibration run does not have to be completed during the first drive following the start of the diagnostics job. It is reset with each power cycle and restarted again until it has been successfully completed. The system can be switched on and off during the calibration process. When the lane departure warning has been calibrated, the primed status display is shown when the lane departure warning is on and speeds over 45 mph and lane markings are detected.

Following a replacement of the control unit, camera or the windscreen, it is necessary to recalibrate the lane departure warning. The driver is notified by a Check Control message if the calibration process cannot be completed successfully after 7 minutes of straight-ahead travel at over 38mph.

The system then makes an automatic attempt to carry out calibration again. The calibration process repeats itself until calibration has been successfully completed. If the calibration run does not complete successfully, the vehicle must be brought into an automotive service facility. There, the calibration process can be terminated manually using a scan tool.