Replacing a vehicle’s brake fluid today typically requires more tools and expertise than a glass bottle and clear tubing. Old-school methods like the two-person or gravity bleeding techniques still work, but they are not efficient at replacing large volumes of brake fluid or servicing ABS-equipped brake systems.

Flushing and bleeding are essential skills if you intend to replace hydraulic components on a vehicle.

Machines and devices that can power- or pressure-bleed a system can make a fluid flush as efficient and profitable as possible.

Power and pressure bleeders are changing along with the systems they service. In the past, only 15-30 psi was required to pressure-bleed the system. But some new ABS modulators with electronic brake proportioning may need 50-60 psi to bleed or flush the system. If you can’t get your pressure bleeder to work under these conditions, look at the service information for the required equipment or pressure setting.

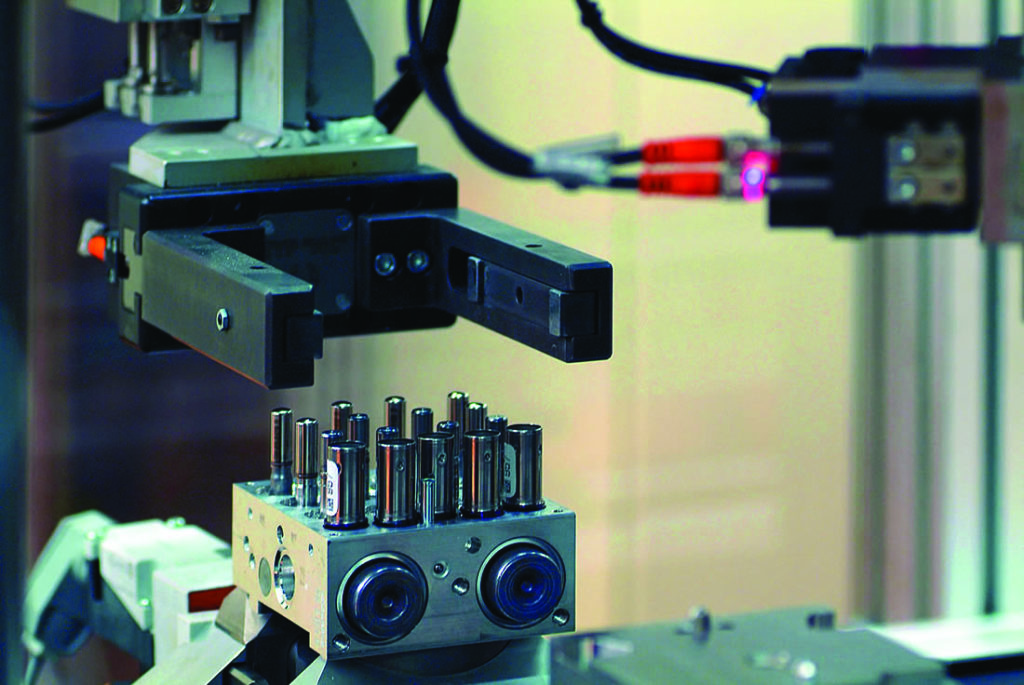

No bleeding method will thoroughly flush the volume of fluid that is in the ABS modulator. Inside the modulator, there might be as much as five ounces of dirty fluid after flushing. The only sure way to flush this fluid is to use a scan tool to actuate the valves in the hydraulic control unit.

Bi-Directional Control

Most ABS systems are not active during normal braking. The brake fluid inside the modulator is moved when the ABS or stability control makes corrections. On some vehicles with electronic brake distribution, the modulator might be active during most stops. Small amounts of the fluid move when the vehicle is started and the valves are actuated as part of a self-diagnostic procedure.

As indicated, the ABS modulator can carry as much as five ounces of fluid in its channels and accumulators. To remove all of the air and old fluid from these systems, some scan tools have automated bleeding procedures, depending on the make and model. If this option is not available, you can perform bi-directional activation of the individual valves in the ABS module to try to remove air pockets. Realize, though, that some systems may have 12 solenoids and valves or more to control the brake pressure at the wheels.

The last resort method is to try to activate the ABS modulator during a stop. This can include braking on a dirt road or performing a sudden stop. But this still might not get all the air out.

When air is in the base brake system, it can cause a low pedal, longer than normal stops and even pulling when the brakes are applied. Not removing the air from the ABS system can cause similar problems. But these symptoms might be intermittent. The customer may pull away from the shop with a firm pedal. All of a sudden, the brake pedal might go to the floor after a few stops.

When debris gets trapped inside the ABS module, it can prevent the solenoids from fully closing after opening. Depending on which valve is obstructed, the driver can experience a hard or low pedal. Also, obstructions can cause the steering to pull when the brakes are applied.

Don’t Feel Bad About Selling Brake Fluid Services

Shops often take a beating from the media for selling brake fluid flushes. The reason consumer advocates complain about it is that the owner’s manual rarely indicates the need for a fluid flush service interval in the maintenance schedule – brake fluid maintenance typically falls outside the range of the service schedule. But if you read deeper into the service information and owner’s manual, OE engineers do say brake fluid is an item that should be regularly inspected and replaced if contaminated.

The hydraulic control unit needs fresh brake fluid to operate and protect valves and passages from corrosion. An additive package helps control the pH, cavitation and viscosity.

Heat and physical stresses on the base fluid and additive package can cause brake fluid to break down over time. Once the additive package is depleted, damage to the brake system can quickly occur.

Another major enemy of brake fluid is moisture. Having a brake fluid with a high boiling temperature is necessary to withstand the heat that can be generated from heavy brake use, such as that associated with multiple hard stops or driving on steep terrain. While most of the vehicles coming into your shop will probably contain DOT 4, you should be aware of how water in the various fluids impacts the boiling point.

Test strips are available that employ copper-testing technology, and they are used as an indicator of corrosion occurring in the brake system. Most brake tubing is manufactured using the Bundy process. This process uses copper-coated low-carbon steel to form double-wall tubing with protective coatings that prevent corrosion to the outer surface of the tube. Corrosion causes the copper to be leached from the tubing and deposited in the brake fluid.

When these corrosion inhibitors become depleted, they leave the internal parts of the brake system vulnerable to corrosion. There are many variables involved in determining how long it takes to deplete the corrosion inhibitors. Some of these factors include brake fluid chemistry, chemical and thermal stability, brake system design, driving habits of the operator, temperature and road surfaces.