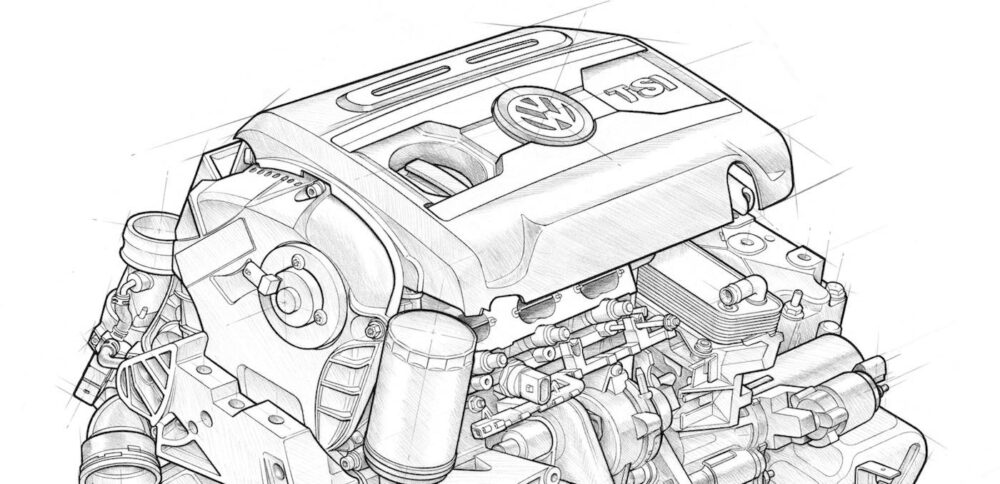

You may have heard the term “DSG” or “DCT” being used when referring to VW/Audi transmissions. DSG, which stands for “direct shift gearbox,” is the marketing term used by VW/Audi for their dual-clutch transmission (DCT). In simple terms, this type of transmission is composed of two separate manual transmissions inside a single case, each one controlled electronically and/or hydraulically.

There are a number of advantages to this type of transmission, but the most important one is this: your customers probably don’t know that their DCT is different from a typical automatic transmission. When everything is working as it should, the DCT should operate seamlessly during their everyday driving.

Construction

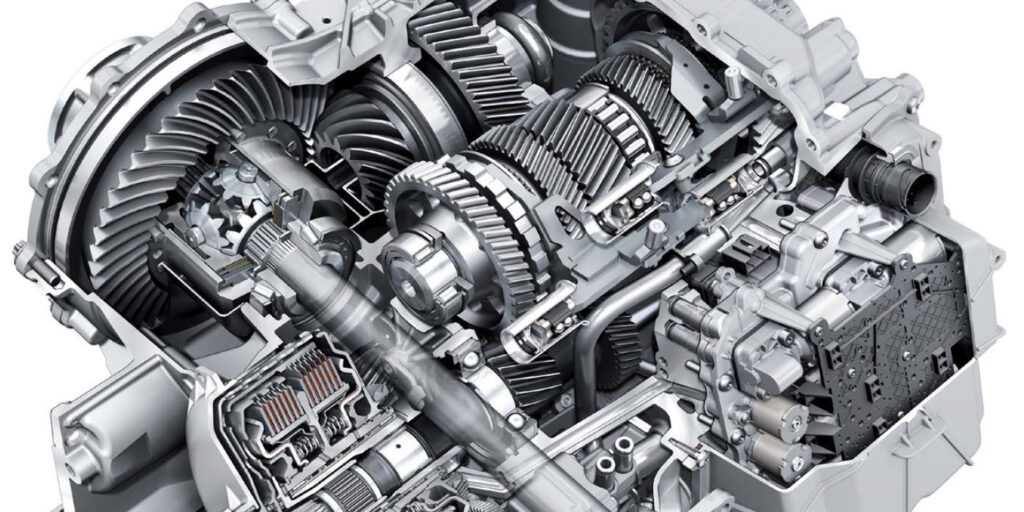

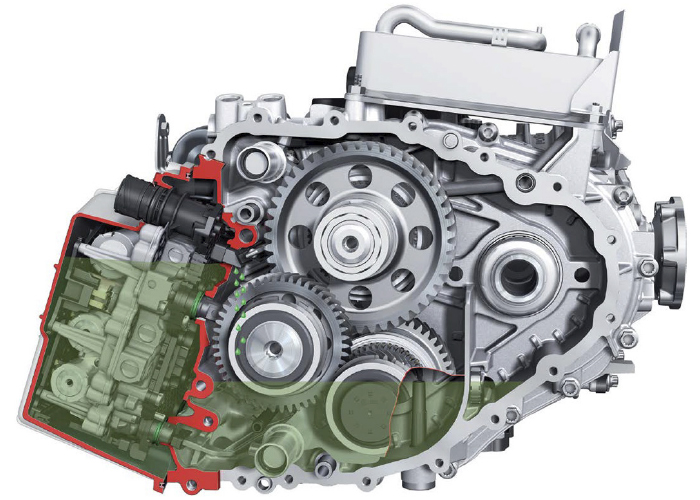

It’s our job as technicians to understand how these transmissions operate, how to diagnose potential issues, and how to make repairs. Let’s start with a brief overview of the internals (figure 1).

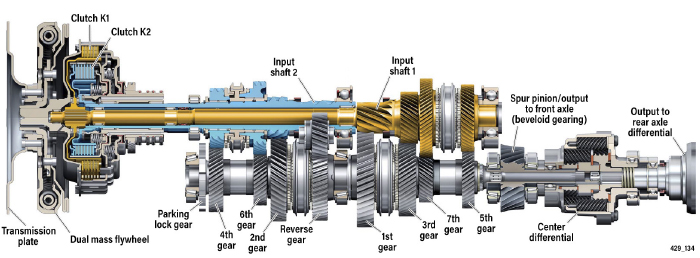

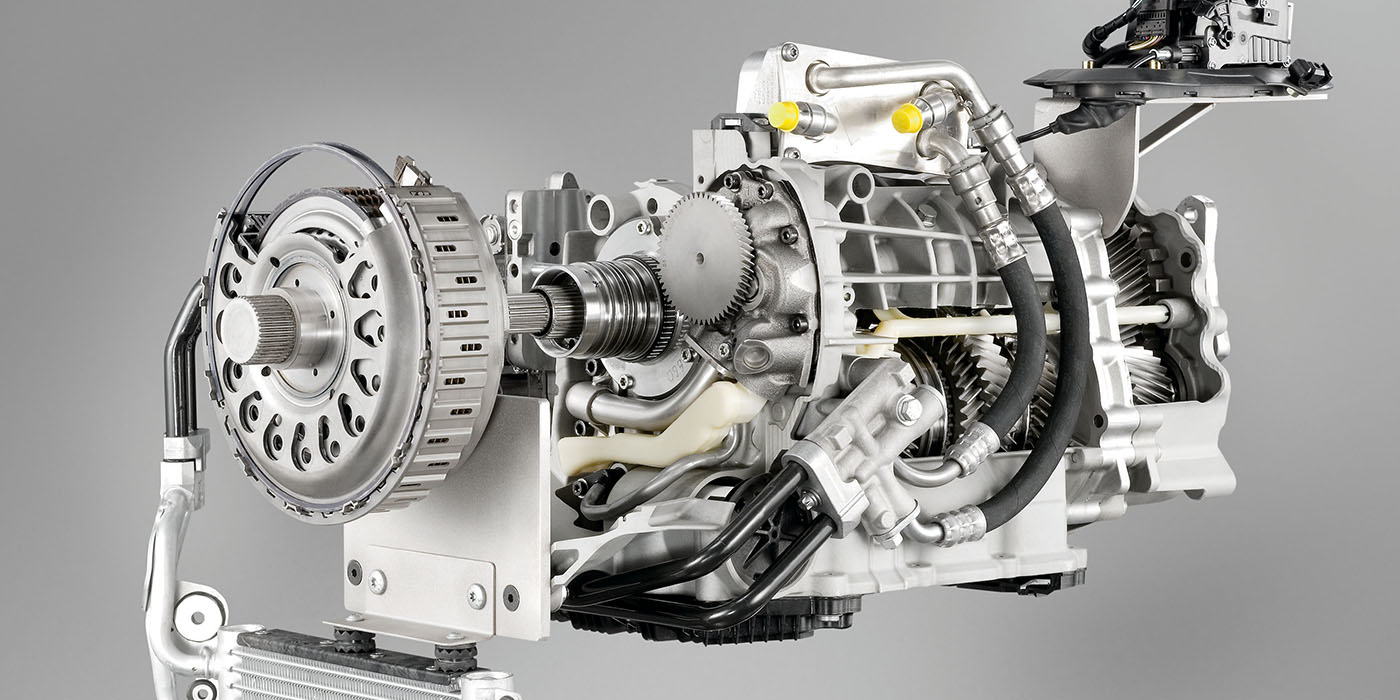

A DCT-equipped vehicle will have a flywheel that mates to the input shaft of the transmission and is engaged by the double-clutch. As the name suggests, the double-clutch contains two separate clutches: K1 and K2. These clutches may be of a wet or dry design depending on the application, but they are always hydraulically actuated. Each clutch engages a separate concentric input shaft; this means that one input shaft fits over the other. The first clutch pack controls the odd-numbered gears. The second clutch pack controls the even-numbered gears (figure 2).

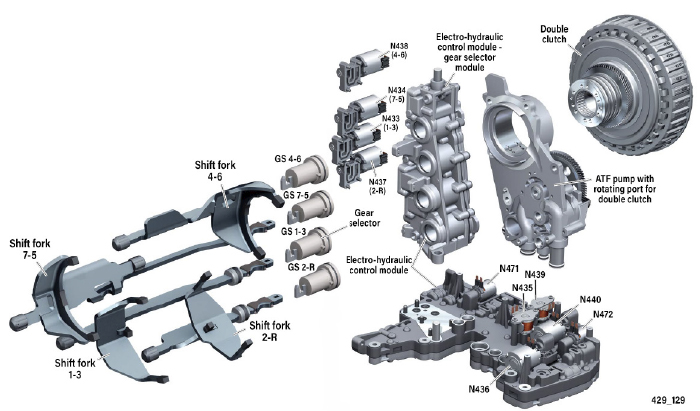

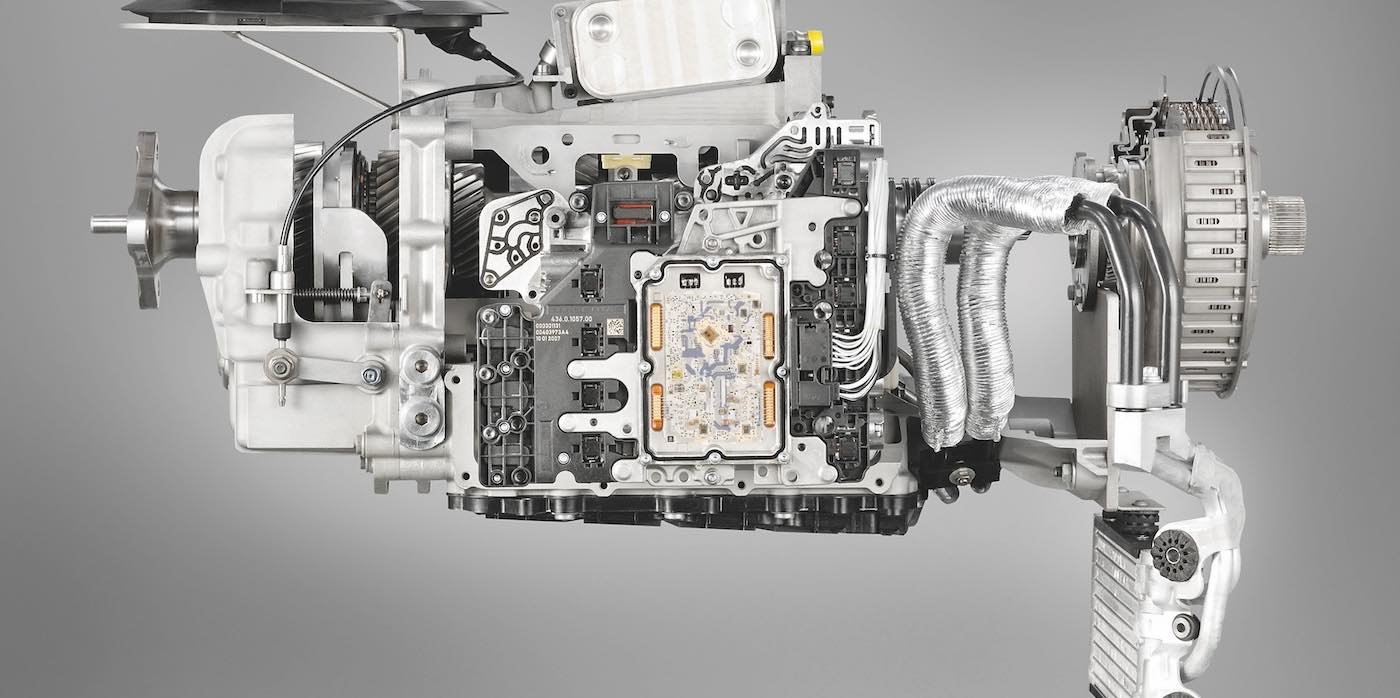

The Mechatronic unit combines the electronic control unit and the electrohydraulic control unit into a single component and controls all transmission functions. The Mechatronic unit has its own oil circuit, which is independent from the oil circuit for the mechanical transmission. This means that any potential foreign material which may be present in the mechanical transmission cannot enter into the Mechatronic unit. The oil in this circuit may be different from the oil used inside the mechanical transmission due to the specific requirements of the Mechatronic unit (figure 3).

Common Issues/Failures

DCTs have proven themselves to be quite reliable over the years. But, as we all know, any mass-produced product can exhibit some common flaws or vulnerabilities over time. Here are a few potential issues you should be on the lookout for whenever servicing a DCT-equipped vehicle. Always remember to start by checking the OEM service information and TSBs. These are probably your best resource for possible remedies/fixes.

It’s probably safe to say that the #1 DCT killer is a lack of maintenance or improper maintenance. If customers fail to follow the maintenance schedule, the oil will wear out or become contaminated with debris. Once this happens, it can all go downhill rather quickly.

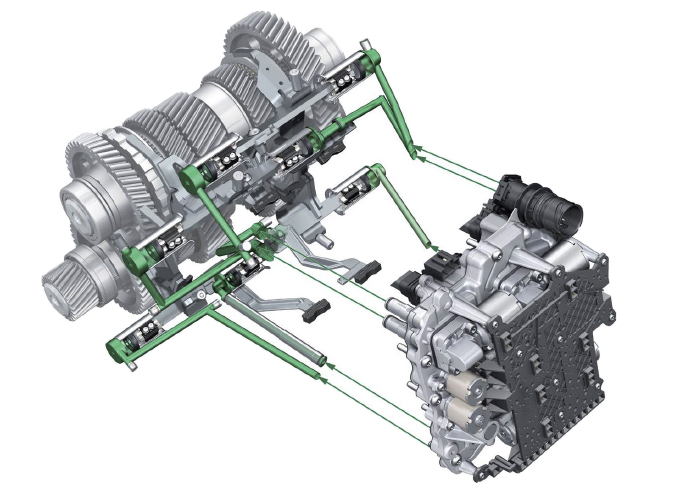

Improper maintenance could mean a number of things. Over- or under-filling the oil will cause hydraulic issues and drivability complaints. Using the wrong type or grade of oil in a DCT-equipped vehicle is also a problem. The oil is specifically formulated to meet the specific needs of the application. Never substitute a different type of oil unless the OEM has specified that it is acceptable (figure 4).

The DCT oil could be contaminated by outside sources. Most DCTs feature a cooler unit mounted on the outside of the case. These coolers use engine coolant to control the temperature of the DCT oil. If the seals fail between the cooler and the transmission, transmission oil and coolant could mix.

Finally, the electrical components inside the DCT could be the source of issues. The transmission control unit (TCU) relies heavily upon data from multiple sensors inside the DCT. A failing sensor can cause a number of drivability concerns such as harsh shifts, shuddering, as well as illuminated warning lights on the dashboard.

Customer States

The most common customer concern is poor shift quality. They may talk about the shifts feeling clunky, rough, harsh or hard. There are a number of potential causes. These include, but are not limited to, a faulty 12V battery, inconsistent throttle application by the driver, worn driveline components, outdated software or recent service.

A battery that is near the end of its life can cause electrical issues. It can cause the TCU or the Mechatronics unit to behave erratically, causing poor gear shifts.

Inconsistent throttle application can “confuse” the Mechatronic unit and the TCU, resulting in erratic shift quality. This is not an indication of a fault; it’s simply a system quirk due to the way the DCT works.

Worn-out CV axles, wheel bearings, engine and transmission mounts can all cause noises and/or vibrations. All of these components should be inspected and repaired if they show signs of wear or damage (figure 5).

Outdated or incorrect module programming may result in sporadic shift quality. This again illustrates the importance of referencing the OEM service information. You may not realize that a simple software update could remedy the entire issue.

If the vehicle has been in for service recently, this could inadvertently cause a shifting concern to manifest itself. If the battery had been recently replaced, all of the ECU/TCU adaptations would have been cleared. This means that the TCU will need to complete a relearn procedure, and shift quality could suffer in the meantime. On the other hand, corroded electrical connections could also wreak havoc with the vehicle’s electrical system.

The most expensive issue that may arise from a DCT-equipped vehicle would be a failing Mechatronic unit. This could show up as hard gear shifts, jerky engagement or the DCT may be completely unable to engage a certain gear. The TCU may go into “limp mode” and reduce the number of gears available to minimize the risk of damage, or it may completely disengage the double clutches and render the vehicle immobile. This scenario will produce stored codes in the TCU. A number of recalls and TSBs have been published on this topic, so be sure to reference the OEM service information while you’re diagnosing the vehicle.

Lastly, there are the clutch packs themselves. As long as the vehicle is not modified, the clutch packs may last for the life of the DCT. However, performance tuning, aggressive driving, and/or a low DCT oil level could lead to premature clutch pack wear/failure.