Air ride diagnostics can be just as complex as any ABS or fuel injection problem. The diagnostic process should start with questions about the system rather than the parts. Failing to find the root cause of a warning light DTC or intermittent problem will typically cause the problem to come back as soon as the customer pulls away from your shop.

The best way to approach an air ride problem is to ask questions. Getting answers to a few fundamental questions about the system and its operation can help you focus your diagnostic skills on the problem instead of the parts.

What type of system are you dealing with?

There are two types of air ride systems: four-corner and two-corner. BMW and other OEMs use air ride systems that have air shocks on just the rear axle. On the other hand, Mercedes-Benz, Jaguar and Land Rover use systems with air springs at all four corners.

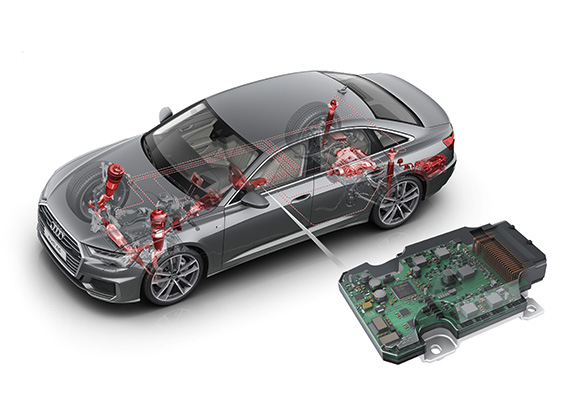

Basic systems just trim the vehicle’s ride height using the rear shocks or struts. They will filter the information from the ride height sensor, typically when the vehicle is static. More advanced two-shock setups like in BMW and Audi models work with active or continuously variable valve dampeners to control vehicle dynamics. Some will even work with active sway bars.

Four corner systems do trim the ride height of the vehicle, but they do a lot more. These systems can optimize the air springs and adjustable valving in the hydraulic dampener to give the best ride while not compromising handling and safety.

Why is this important? Knowing the basic architecture and function will help you find components quicker and carry out leak checks faster.

How is the compressor connected?

Systems can differ in the way they use the compressor. Some systems from Lexus and Toyota pump air directly from the compressor to the air springs. Other systems control the air in the units using a reservoir. The compressor replenishes the reservoir and not the air springs.

If there is no reservoir, the compressor will typically run whenever an adjustment that requires an increase in pressure is requested. If there is a reservoir, the compressor will run only when the pressure is below a specific level and conditions like temperature and road noise are optimal.

Some vehicles can have multiple reservoirs to increase the air capacity. For example, certain Mercedes-Benz E-Class models with Airmatic suspension can have up to three reservoirs.

Why is this important? How the system manages the air pressure in the air springs is critical to diagnosing the compressor.

What is the suspension designed to do?

Entry-level air ride systems are designed to keep the vehicle level when weight is added. More sophisticated systems will use air to improve ride quality and control the pitch and yaw of the vehicle when it is moving.

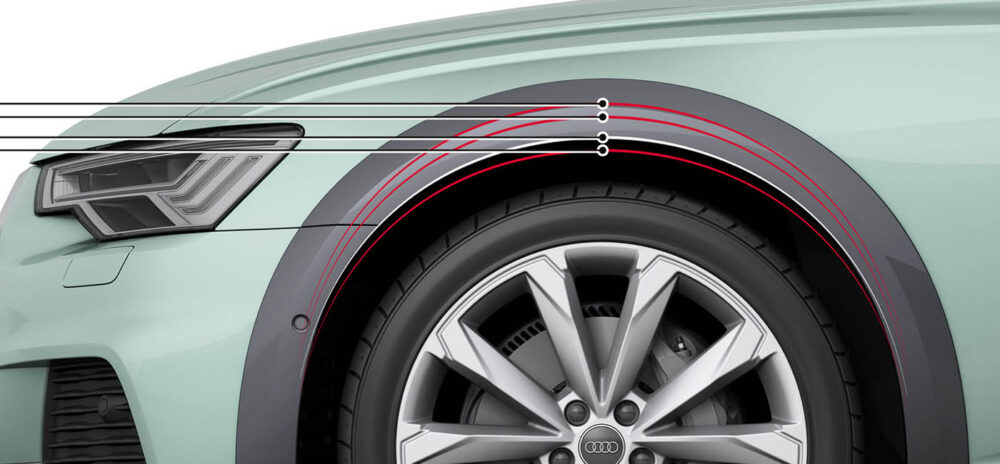

A sign of the complexity of the system corresponds to the number of its ride height sensors. Systems that alter the pressure in real time will have sensors at all four corners. Less complex systems will have one air line, one height sensor and one set of inlet and exhaust sensors per axle. Also, units that are actively tuning the system for road conditions will have accelerometers mounted near the front or rear axles.

Other indicators of the complexity of the system are the number of other modules connected to the air ride system. In some cases, the air ride system might communicate only with the ABS module. Some vehicles will have the air ride module connected to the CAN bus that communicates with the vehicle’s ABS, ECM and BCM.

Why is knowing this important? Knowing what you are dealing with is critical because air ride corrections occur for a variety of conditions. In addition, when a correction is carried out, the system checks the correction with the pressure and ride height sensors.

What is the system doing at startup?

On most air ride systems, when the ignition is turned on, the system performs a self-check and does a little housekeeping. The system may lift the vehicle to a higher-than-normal ride height and then trim to the correct height using the outlet or exhaust valves. On four-corner systems, the rear will typically raise first, followed by the front. This can also help to flush condensation from the air springs.

If the vehicle has electronically adjustable dampening, the valves are typically actuated to the fully open and closed positions. This requires a continuity check to make sure there is no open, short or high resistance in the system.

Why is this important? Most air ride and chassis codes are set in the first minute after the car is started. The self-check ensures that all the sensors and solenoids are functioning. If the compressor runs too long or the pressure drops too much, the system might set a code.

What is the exhaust valve doing?

Exhaust valves on a compressor do more than just lower the suspension. Most systems will open the exhaust valve for less than a few seconds before the compressor is engaged to release air from the compression chamber, ensuring low-current draw during activation.

The exhaust valve also can be used to purge condensation in the compressor and lines. Certain systems might also purge the lines after the vehicle is turned off.

Why is this important? Next to the air springs and compressor, the most likely component to fail is the main exhaust valve mounted to the compressor. If the exhaust valve is leaking or is stuck shut, the system will have multiple failure symptoms.