Advanced driver-assistance systems (ADAS) are currently the fastest-growing automotive technology. Unfortunately, the speed at which ADAS is advancing has outpaced the automotive industry’s ability to keep up with it.

Shops that have no experience with ADAS calibration can be forgiven for feeling a bit intimidated. It’s not easy work. You can’t flip a switch and call it done (at least not without the proper equipment; more on that later). It’s intricate and precise and definitely confusing. Accordingly, many shops take a pass.

Nonetheless: do not be afraid of this type of work. It’s totally manageable, not to mention profitable – possibly seriously profitable – if you commit to due diligence and educating yourself on the basics, one step at a time. And step one is an alignment inspection.

In-House

If you’re not currently doing wheel alignments in-house, why not?

Alignments perennially rank at the top of the highest-margin list. Up to half the vehicles driving around right now need alignments, let alone after a collision. If you inspect for alignment, you’ll always find it.

If you inspect for alignment, you’ll always find it.

That’s why you should do alignments in-house: it’s highly profitable work. Subletting it is not highly profitable, at least not for you. A $100 in-house alignment will net you $70. A $110 alignment someone else does will net you $10. Then there’s the transport risk, additional customer wait, towing reimbursement and quality control. It’s more money, less time and surely less trouble to do the work yourself.

Alignment and ADAS

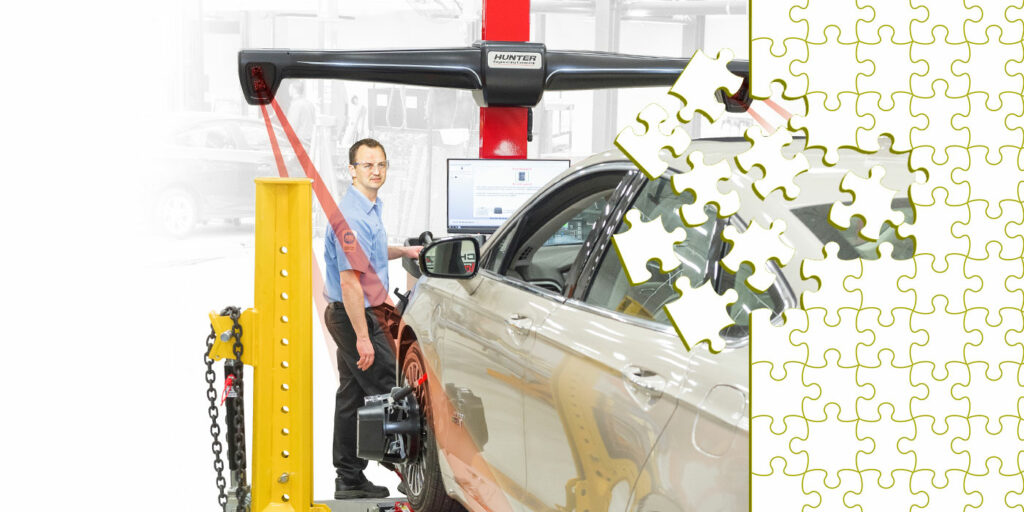

Now, add an even better reason to do alignments in-house: wheel alignment and ADAS calibration connect like pieces in a jigsaw puzzle. If you don’t know where the wheels are going, you don’t know where the ADAS is going. ADAS systems that follow misaligned wheels, rather than the direction of travel, can’t do their job properly.

Every ADAS calibration starts with an alignment inspection. Wouldn’t it be nice if there were a lot of calibrations to do? There are.

More ADAS Coming

What autonomous vehicles are attempting to do for driving – that is, take driving out of the actual driver’s hands – ADAS is attempting to do for safety.

Today, more than 60 million vehicles have ADAS components, and that number will only increase: AAA states that 96% of 2020 vehicle models came equipped with at least one ADAS function. In 2023, automatic emergency braking will be required. Other safety-related features such as antilock braking, electronic stability control and backup cameras are already mandated. Unless you find yourself working on a Nash Rambler, it’s likely best to assume the vehicle has ADAS.

Wheel alignment and ADAS calibration connect like pieces in a jigsaw puzzle.

This rapidly evolving technology is a game-changer for the repair industry. As manufacturers continue to refine these sophisticated systems, the need for shops skilled in identifying, diagnosing and calibrating ADAS will only grow. That’s because manufacturers now require ADAS calibration under a wide set of circumstances. Here’s a current snapshot:

- Twenty-eight vehicle manufacturers require a calibration following a collision or safety component replacement. If you’re a body shop, that means pretty much every vehicle that makes it to your lot will need a calibration before it leaves.

- Many require a calibration following a host of common repair procedures, including windshield replacement, repairs to front or rear suspension or steering, changes in ride height, changes in tire size, any repair that requires the R&I of an ADAS component, and more.

- Eleven of those 28 manufacturers require a calibration following a wheel alignment, including Ford, Volkswagen, Jeep, Kia, Dodge and Subaru.

That covers millions upon millions of vehicles.

ADAS is no longer something shops can avoid or ignore. They’ll either adapt or consent to losing a lot of business to shops that did.

Table Stakes

So far, avoiding or ignoring may be the rule rather than the exception. It’s not clear that this required work is taking place on the scale that might be expected. This is likely because shops don’t know the extent to which they’re required, or because they lack the expertise or equipment to perform the work. They refer calibrations elsewhere, or just skip them entirely.

This is not an ideal scenario, from either a safety or business perspective. It doesn’t seem sustainable.

Safety

There are two types of ADAS functions: passive, where the driver is alerted to a situation, and active, where the vehicle takes automatic action, such as emergency braking. Drivers will increasingly rely on these automatic functions – again, think self-driving cars – and thus it’s critical that ADAS always works as intended.

Since safety is involved, liability is involved. The work must be responsibly done. A calibration where a camera or radar system is a half-degree off becomes a massive five feet at 200 yards. This can cause the system to see things that aren’t there and not see things that are.

In other words, if you’re going to do ADAS calibrations, then you have to do ADAS calibrations. Your name is on it.

Expansion of Services

Some shops may see these requirements as a burden they would rather put on others’ shoulders by subletting it out. Wiser shops will see the new ground rules as an opportunity to significantly expand their services. If fewer shops are attempting this sort of work, all the better – a lane widens for those who commit to becoming proficient. That’s not only how to best serve your customers, but it simply makes good business sense. Depending on the extent of the requirements, ADAS work can run from $250 to S1,000 or more.

If you keep alignments in-house, you keep ADAS in-house. Eventually, the ability to competently perform this work will be regarded as table stakes. Each shop will need to decide if it’s going to make a virtue out of necessity and adjust – or not. ADAS offers the chance to differentiate from the pack and become known as a shop that “gets” safety systems.

Becoming an Expert

Back to where we started: alignments.

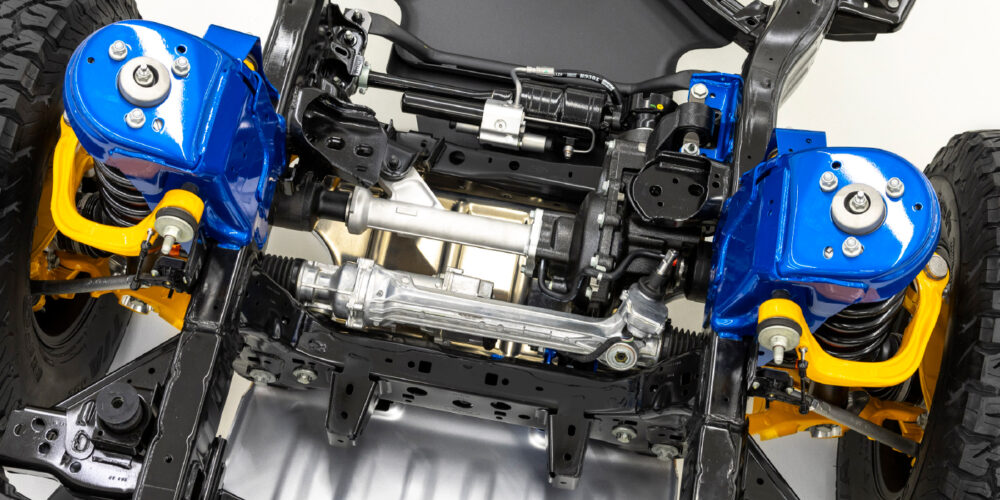

Manufacturers require proper wheel alignment because ADAS must follow where the car is going, not wherever the bumper is pointed. The key measurement is the thrust line, not the center line. And it’s impossible to find the thrust line outside of an alignment rack.

But alignment is the easy part; everything that follows is a lot trickier. So if you want to become an expert at ADAS, take advantage of expert systems.

Wheel alignment equipment is now available with built-in ADAS alignment capabilities. These alignment and calibration systems guide techs step by step through dynamic or static calibrations for millions of vehicles. Full-diagnostic scanners integrate with the aligner and other ADAS fixtures, ensuring that complicated procedures are completed according to OE requirements and thoroughly documented for insurance. Services that provide live, online calibration assistance are also an option.

ADAS specifications change frequently, not only from brand to brand but vehicle to vehicle within the brand. So relying on updated, expert help is a smart business move.

Summary

The less you know about ADAS, the scarier it is. To get started, stick with brands you know, educate yourself and your staff, and above all else, be patient. You won’t master ADAS in a day. But the more you know, the sooner you’ll move from a shop that sends ADAS work to others to a shop that others send ADAS work to.

This article is courtesy of Body Shop Business Magazine.