Many import nameplate manufacturers started to offer Advanced Driver Assistance System (ADAS) options as early as 2005. These systems include automatic braking, lane keep assist, collision avoidance, adaptive cruise control and other systems that can intervene or help the driver when potential dangers are detected when the vehicle is being driven.

These systems use cameras, lasers and radar to detect other vehicles, pedestrians and markings in the road. These systems also use information from sensors like the steering angle, steering torque and even yaw/lateral acceleration. But, the vehicle needs to be accurately aligned for most of these systems to work.

Most manufacturers recommend that at least the steering angle sensor be recalibrated after any front or rear toe adjustments are made during an alignment.

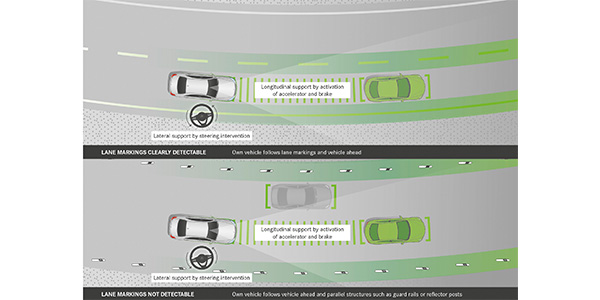

It all comes down to measuring three things. First, an ADAS system measures what the driver wants the vehicle to do with inputs like the steering angle/torque and brake pedal position. Second, the system is measuring what the vehicle is doing using the wheel speed sensors, accelerometers and yaw sensors. The data from these three sensors can determine if the vehicle is understeering or oversteering in a corner. Third, cameras and radar look forward to see what is in front of the vehicle. The three measurements of an ADAS system are affected by the alignment of the vehicle as it relates to the toe and thrust angle.

ADAS Advanced Alignment

If a camera or radar sensor is moved from its mounting during a repair, it must be recalibrated using the manufacturer’s procedures. An example is replacing a timing chain/belt on some Audi models that require the radiator core support to be removed. Since the forward-facing radar is removed during this repair, it needs to be calibrated. Likewise, if a windshield is replaced, the camera might need to be aligned.

If the radar’s beam or camera’s field of view is altered by either a change in the sensor’s mounting points or the thrust angle, you could get false activation or deactivation of the ADAS system. For example, if the camera or radar sensor is pointed upward, the system might not correct the speed of the vehicle until it detects the top of the vehicle and not the bumper. This type of immediate correction can cause a driver to panic if they are using automatic cruise control. If the beam or camera is aimed a few degrees to the side, it might pick up parked cars and road signs, and needlessly activate.

Adaption and Calibration

There are two ways for an ADAS system to be calibrated. One method involves using targets mounted to a fixture at precise distances from the sensors. The targets have patterns that the vehicle’s camera recognizes or that can reflect the beam. The recalibration process is initialized with a scan tool. The other method is a self-learn test drive that is also initiated with the help of a scan tool.

In some cases, it might take several hours and multiple test-drives for the system to be calibrated. This is often the case if the system has pedestrian detection.

Awareness is half the battle with ADAS. Knowing that there is a camera behind the windshield or a radar unit behind the grille can help you make the correct choices before, during and after an alignment or repair.

If you do get a vehicle with lane departure or automatic braking in your shop for any repair, including maintenance, connect your scan tool to see if it can communicate with the modules and possibly perform a recalibration procedure. Doing this before you are under the gun to align a vehicle can help you make better tooling and training decisions.