Behind every kind of technical innovation that drives the automotive world into the future is a wealth of science and engineering that makes such innovation possible. The emergence of precious metal spark plugs is no different.

Behind every kind of technical innovation that drives the automotive world into the future is a wealth of science and engineering that makes such innovation possible. The emergence of precious metal spark plugs is no different.

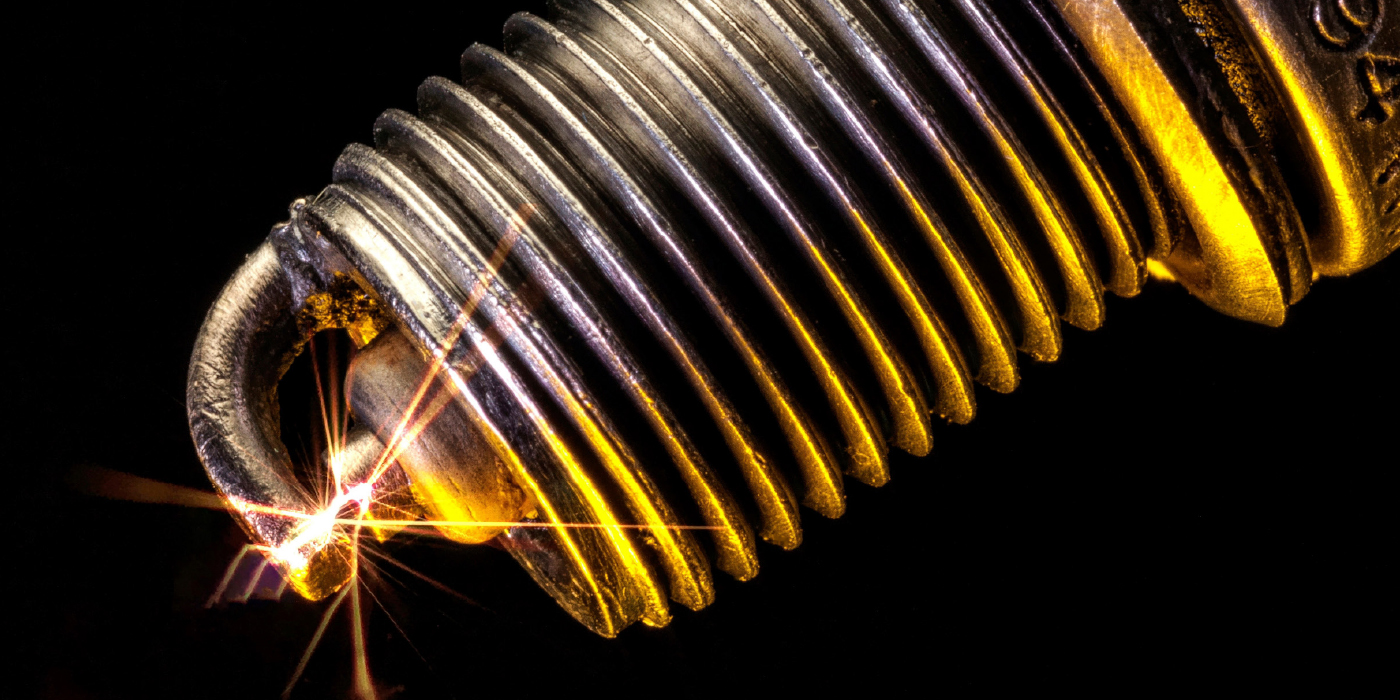

With the need to comply with ever-increasing efficiency and emissions standards, auto manufacturers have been racing to raise the bar in spark plug performance over the past three decades. The use of precious metals like platinum and iridium in the manufacturing of spark plugs, as opposed to the use of conventional materials, has resulted in plugs that can last much longer and offer better performance than the spark plugs in circulation prior to the mid-1980s. Specifically, precious metals were introduced into the spark plug manufacturing process because of their higher melting points: The melting point of iridium is 2,450 °C, platinum is 1,770 °C, and nickel is 1,453 °C.

The higher melting point of iridium and platinum allows spark plug manufacturers to reduce the diameter of the center electrode. The smaller the diameter of the center electrode, the lower the voltage needed to generate a spark. The finer point means that the electrode can absorb heat easier and faster, leading to improved acceleration, reduced fuel consumption and smoother idling.

Copper Spark Plug Basics

Copper Spark Plug Basics

Copper spark plugs have bodies made of copper with center electrodes comprised of nickel alloy. These plugs require more voltage to function than precious metal plugs. Because nickel alloy is softer than iridium or platinum, copper plugs wear out sooner than precious metal plugs. (Many have a recommended service interval of around 30,000-50,000 miles). For this reason, copper plugs are best used in older vehicles with conventional distributor ignition systems. It should be noted that while copper plugs are usually best for older vehicles, some newer vehicles with high-performance engines are designed for copper spark plugs. Always make sure to consult the owner’s manual if there is a question as to which type of spark plug replacement is recommended.

Platinum Spark Plug Basics

Platinum Spark Plug Basics

Platinum spark plugs were introduced in the mid-1980s and quickly gained favor for their heat-resistant and wear-resistant properties that allowed them to last upward of 100,000 miles in some instances without needing replacement. Platinum plugs run hotter than copper plugs. This helps reduce deposits and prevent fouling. While these plugs offer high performance and a longer lifespan, they do come at a cost. Typically, platinum spark plugs cost two to four times that of traditional plugs, but can make up the cost differential with their longevity. Use these plugs with newer cars with electronic, distributor ignition systems. Some distributor-less systems require these plugs as well.

Iridium Spark Plug Basics

Iridium Spark Plug Basics

Iridium spark plugs entered the market in the mid-1990s. Because iridium is one of the world’s hardest metals, it is very resistant to spark erosion. On these spark plugs, Iridium’s properties reduce the ignition voltage requirement considerably and contribute to improving the spread of the flame front in the combustion chamber. The service life of iridium plugs is more than double that of standard plugs, and can be up to 25 percent longer than platinum plugs.

Double Platinum/Double Iridium Spark Plugs

Double platinum and double iridium spark plugs were developed for use in waste spark ignition systems. In these applications, both the center electrode and side electrode feature precious metal discs to prevent excessive electrode wear. Waste spark ignition systems fire the spark plug during the power and exhaust stroke causing double the amount of wear.

Replacement Intervals

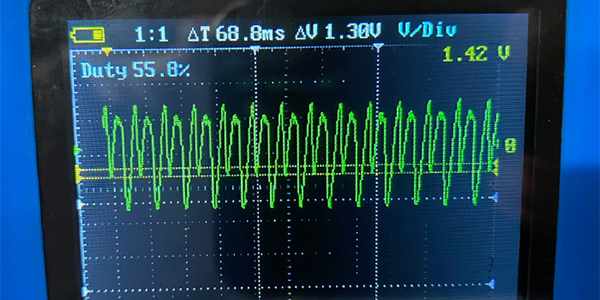

Factory-recommended spark plug replacement intervals have consistently been in the 100,000-120,000-mile range in recent years thanks to the efficiency of precious metal plugs, but these spark plugs can continue performing well long after these intervals have been reached. However, it is important to keep an eye on spark plug performance as they approach 100,000 miles of use. As electrodes wear over time, spark plugs require more voltage to fire. If this wear goes undetected, the strain can cause misfires.

Misfires need to be promptly addressed, as they lead to a loss of power and fuel economy. What often goes unnoticed, though, is that misfires also lead to an increase in unburned hydrocarbon emissions. When this goes undetected, the catalytic converter can become overheated due to the excess of hydrocarbon it has to process. Overheating is a major cause of catalytic converter damage, and often necessitates catalytic converter replacement when not addressed.

Installation Best Practices

Always make sure that when replacing spark plugs, you use parts with the same thread diameter, pitch and length as specified by the manufacturer.

According to one spark plug manufacturer spokesperson, “Technicians should keep in mind that most of the newer model vehicles come out of the factory with precious metal plugs, and they should be replaced with similar OEM-style plugs. Installing alternate plugs might cause loss of fuel economy and performance.

“Also, there is a myth that the fine-wire precious metal plugs should not be gapped. That is a false statement. You should always double-check the gap using a wire-style gapping tool. We do not recommend using the ‘coin’-style gapping tool because it can damage the fine wire tip.”

Change comes quick in today’s automotive aftermarket. And while the size and shape of spark plugs might condense in the future to better fit shrinking engine compartments, the use of precious metal spark plugs is something that is expected to continue into the foreseeable future.

“I think the material choices are going to remain fairly stable,” said a representative from another manufacturer of spark plugs. “Not that we’ve reached the pinnacle, but between iridium and platinum materials and the way they are alloyed with different metals, I think we’re really at the top of our game with respect to what materials function the best in those environments and last the longest. Unless there is a major shift to some new and significant raw metal material, I can’t see the iridium or platinum plugs going away any time soon.”