Q. What types of wheel bearings are used on vehicles today?

Q. What types of wheel bearings are used on vehicles today?

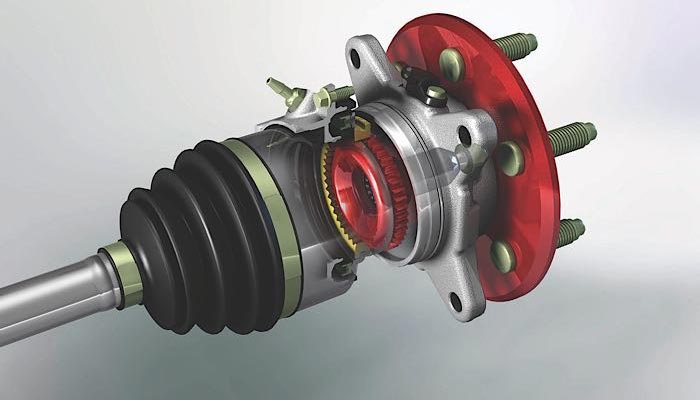

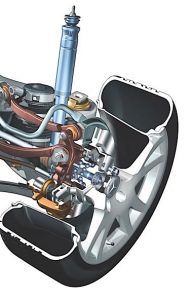

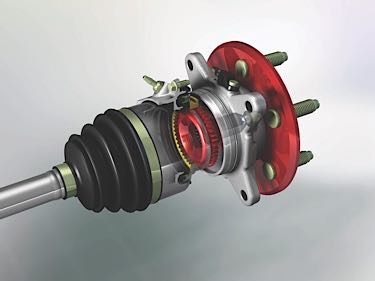

A. There are many different types. Most wheel bearings on late-model vehicles are part of a sealed hub assembly or cartridge. Sealed hub assemblies may be used on front-wheel-drive (FWD) as well as rear-wheel-drive (RWD) cars and trucks. Press-fit cartridge-style wheel bearings are often used in the knuckles of FWD cars. Bolt-on hub assemblies, where the wheel bearings are sealed inside the hub, also are commonly used both front and rear on many vehicles. Sealed cartridges or hub assemblies do not require periodic maintenance or adjustments. However, they should be inspected when rotating tires, doing a brake job or other suspension-related repairs to make sure they are in good condition.

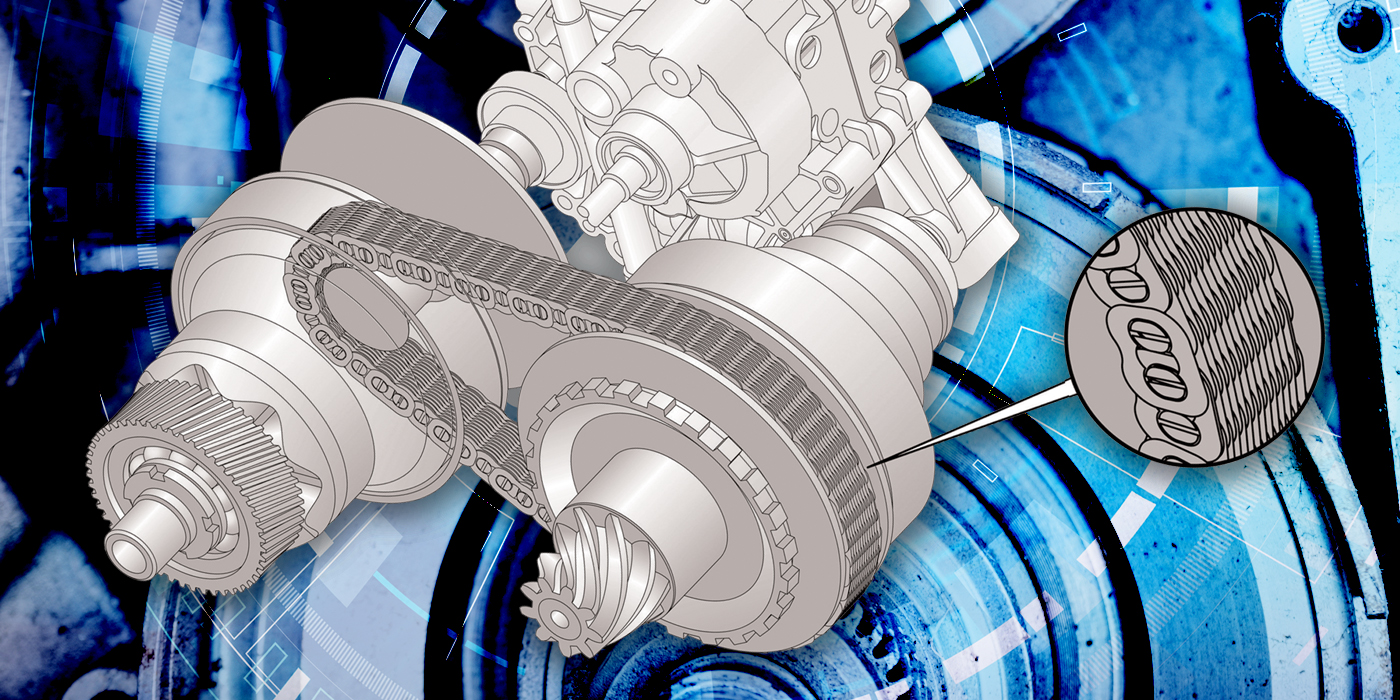

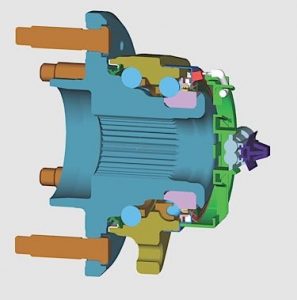

A sealed hub assembly or bearing cartridge typically contains two sets of bearings: an inner set and an outer set. They may be ball bearings or tapered roller bearings. Tapered bearings have cylindrical rollers between the inner and outer race. The rollers are held in place by a steel or phenolic cage. The rollers are larger on one end than the other and rotate in a cone-shaped path. This allows the bearing to handle both sideways and vertical loads. The larger surface area of tapered bearings allows them to support greater loads than ball bearings, which is why tapered bearings are often used in larger, heavier vehicles.

A sealed hub assembly or bearing cartridge typically contains two sets of bearings: an inner set and an outer set. They may be ball bearings or tapered roller bearings. Tapered bearings have cylindrical rollers between the inner and outer race. The rollers are held in place by a steel or phenolic cage. The rollers are larger on one end than the other and rotate in a cone-shaped path. This allows the bearing to handle both sideways and vertical loads. The larger surface area of tapered bearings allows them to support greater loads than ball bearings, which is why tapered bearings are often used in larger, heavier vehicles.

Double-row ball bearings have round steel balls between the inner and outer race. Like roller bearings, the balls are held in place by a steel cage. Ball bearings are less expensive to manufacture than tapered bearings and produce less friction, which helps improve fuel economy. However, ball bearings don’t handle severe side loads as well as tapered bearings. As such, they may not stand up well to severe sideloading created by hard cornering or racing.

Wheel bearings are made of high-grade steel, and the inner and outer races (called the cone and cup), as well as the rollers or balls, are all heat-treated to harden their outer surfaces. This improves wear resistance and the bearing’s ability to handle loads. Most wheel bearings are capable of lasting upward of 200,000 miles under normal driving conditions.

Premature bearing failure can occur if outside contaminants such as water, dirt or road salt get past the bearing seals and enter the bearing. This can lead to corrosion and wear, and ultimately, bearing failure. Grease leaks also can kill a bearing very quickly. The loss of lubricant can lead to spalling, flaking, pitting, cracking or even bearing seizure.

Q. How can you tell if a wheel bearing is failing?

Q. How can you tell if a wheel bearing is failing?

A. Grease streaking radiating outward from the hub is a sure sign the seal that protects the bearing is leaking. If this is present, the bearing is doomed and needs to be replaced.

Any noise (squealing, chirping, squeaking, whining, humming, rumbling, etc.) from the vicinity of the hub is another clue of a failing bearing. The sound may come and go at various speeds, or be heard all the time.

Any visible looseness in a wheel is also a sure sign of wheel bearing trouble. Such a vehicle may be unsafe to drive, and repairs should be made without delay. If a wheel wobbles when it rotates, the cause could be a loose wheel bearing, a bent spindle or a bent wheel. Further investigation is needed to determine the exact cause.

On most vehicles with sealed bearing assemblies, the amount of play allowed is typically no more than 0.003 to 0.004 inches. More than 0.005 inches of play is too much and usually indicates a bad bearing. On older RWD cars and trucks with serviceable wheel bearings, up to 0.010 in. of play may be allowed depending on the application.