In a second engineering field study of more than 6,800 discarded brake pads, the Global Brake Safety Council (GBSC) analyzed why the brake pads were replaced. The significance of this field study for parts manufacturers is that it provides a window into how brake pads perform in the field under real-world conditions.

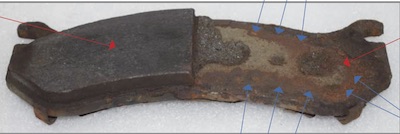

The conclusion of the study was corrosion is playing an increasing role in the failure of brake pads. Also, corrosion and backing plate quality are becoming the leading limiting factor that is preventing consumers from getting the full life of the friction material.

The field study collected brake pads from Toronto, Northeast Ohio and Houston, TX. The pads were analyzed at the NUCAP Industries R&D facility. Combined with the samples from the first field study, the sample size is more than 10,000 part samples and represents all four seasons.

Findings

• 61.9% of the brake pads had 50% or more of the friction material remaining with no visible delamination or separation.

• 6% of the pads were worn to the backing plate and came in contact with the rotor.

• 11.8% had significant enough corrosion that the shim de-bonded and the pad abutments surfaces were compromised.

• 27% of the samples showed signs of friction material edge lift. This “rust jacking” was more prominent from the samples that came from Northeast Ohio.

• 6.3% of the pads partial or total separation of the friction material from the backing plate.

The field study concluded that many of the failures are related to the backing plate design, materials and how the friction material was attached. Also, regional weather factors like snowfall and the de-icing usage can accelerate failure modes like delamination and edge-lift.

To read Part 2 of the study, click here.

To read the full, original study from the Global Brake Safety Council, click here.