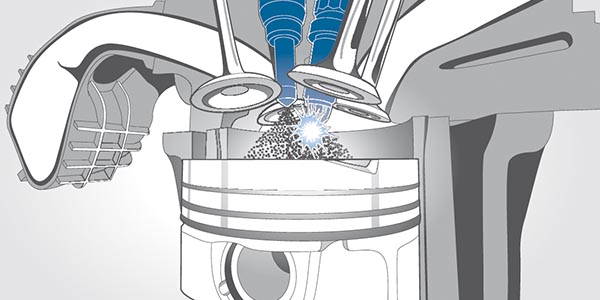

When a spark plug fires, it is not an instantaneous ignition of all the molecules of air and fuel. When the spark kernel jumps between the two electrodes, the piston might be some distance from the top of the cylinder (this is usually described as degrees of crankshaft rotation).

As the piston is traveling upwards compressing the air and fuel, the flame front is starting to spread outwards from the electrodes of the spark plug burning air and fuel and building pressure. How the flame front spreads is dependent on a lot of factors including the ratio of air to fuel, combustion chamber design and other factors only an engineer would understand.

As the piston reaches the top of the cylinder and just starts to travel downwards on the power stroke, the flame front and pressure wave is just starting to reach its peak. As the piston travels downwards after top dead center, the peak combustion pressure is reached.

If the flame front starts too early, it can cause pre-ignition. Pre-ignition is very damaging because of two dynamics inside the cylinder. When the flame front starts to early, the engine is compressing the high pressure of the combustion event into the smallest possible area of the cylinder. Also, if the peak pressure builds before top dead center during the compression stoke, the extreme pressure can cause damage to the piston, crankshaft, connecting rod and, in some cases, cause the head to lift from the block.

Another type of misfire that can occur is when a second flame front happens. This can be started by a hot spot on the surfaces in the combustion chamber due to carbon buildup or from oil droplets igniting due to heat and compression. This creates a second flame front and pressure wave in the cylinder that collides with the flame front started by the spark plug. This phenomenon is often called knock.

If the ignition of the air and fuel mixture does not occur or reached peak pressure after the cylinder has long passed top dead center, it is less damaging to the combustion chamber, but it can be damaging to the emissions components of the vehicle.

Misfires are bad news because they cause a noticeable loss of power and fuel economy, and a less obvious, but very measurable increase in unburned hydrocarbon (HC) emissions. The catalytic converter can take care of the extra HC up to a point, but a steady misfire can make the converter overheat. If the converter gets too hot, it may suffer irreparable damage resulting in a power-robbing exhaust restriction or a loss of efficiency.

The oxygen sensor sees a misfire as extra oxygen in the exhaust stream; it does not see the fuel. When the extra fuel is burned in the converter, the extra fuel is seen in the reading between the oxygen sensor before and after the catalytic converter.

How The Engine Sees A Misfire

Any time you’re dealing with a combustion engine, there’s a chance it will develop a misfire. A better understanding of how computer systems analyze a misfire can make your job that much easier as the technician who’s diagnosing the problem.

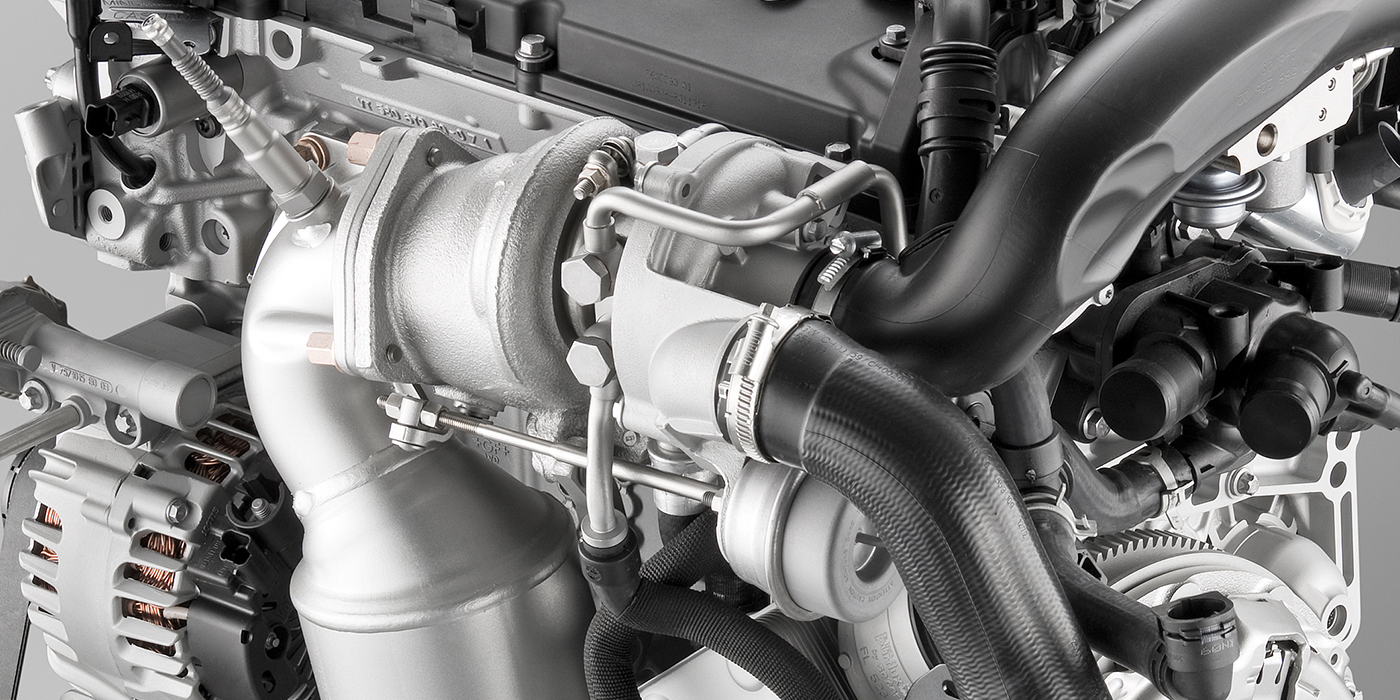

With most engines, the crank sensor is the key component in determining a misfire. The PCM calculates the time between the edges of the crank reluctor wheel teeth by receiving a signal from the CKP sensor. The crankshaft rotational velocity and acceleration are compared in the event of a power loss from each cylinder.

What Causes A Misfire?: Spark

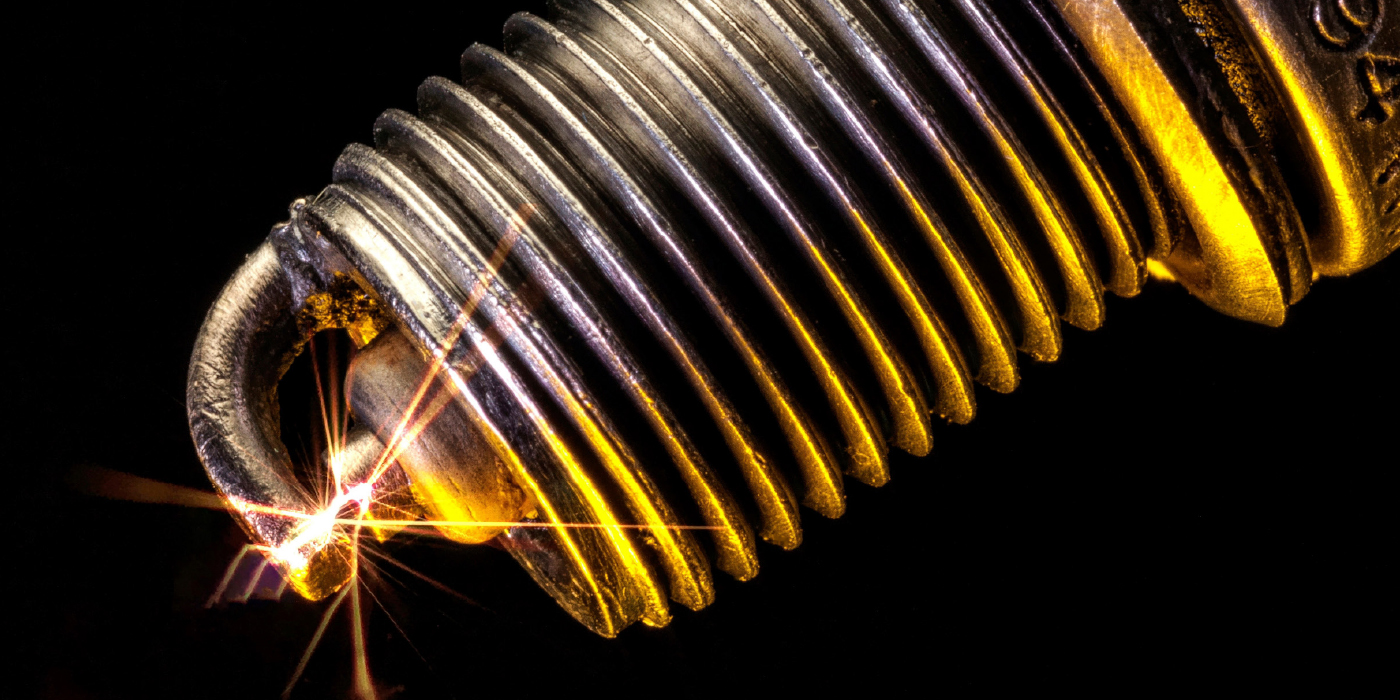

Every time a spark plug fires, the spark burns a few molecules of metal off the plug’s electrodes. Over time, this eats away the electrodes and rounds off their sharp edges. The erosion gradually increases the gap between the electrodes, which, in turn, increases the firing voltage required to generate a spark. Eventually, the ignition system reaches a point where it fails to produce enough voltage and the plug misfires.

Spark plugs encrusted with oil ash indicate that oil might be leaking through worn valve stem seals or piston rings. If the piston head is washed clean around the edges or across the dome, the oil is washing around worn or stuck piston rings. If the piston is dry and the oil ash is primarily accumulated on one side of the spark plug, the oil is likely entering the cylinder through a worn valve stem seal or guide.

Another common failure in COP ignitions is carbon tracking or “flash over” on the spark plug insulator. A severely eroded spark plug electrode will increase firing voltages so much that the spark will seek the point of least resistance, which is either through the spark plug boot or down the insulator to the metal shell. If a carbon track is found on a spark plug, an identical track will be found inside the spark plug boot.

If the boot is serviced as a replacement part separate from the coil, the boots should be replaced at the same intervals as the spark plugs. If the boot is available only with the coil assembly, the spark plugs should be replaced at the recommended intervals and care should be taken not to contaminate the boot or insulator with dirt or oil.

What Causes A Misfire?: Fuel/Air

A condition known as “lean misfire” can occur if there is not enough fuel in the combustion chamber. Lean misfire causes that only affect one cylinder include a dirty fuel injector, an open or shorted fuel injector, or a problem in the fuel injector driver circuit (wiring or PCM). Compression problems that may cause a misfire include a burned exhaust valve, bent intake or exhaust valve, or leaky head gasket.

An individual cylinder with a rich fuel mixture is not as common as a lean mixture, but it can occur if the fuel injector leaks.

A more common condition would be a rich mixture in all cylinders caused by 1) a dead oxygen or coolant sensor that prevents the computer from going into a closed loop, or 2) a faulty fuel pressure regulator or plugged fuel return line that is routing too much pressure to the injectors.

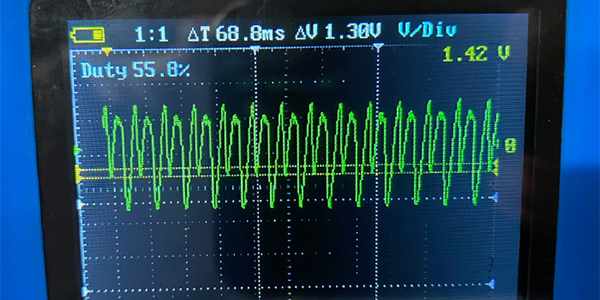

Something else to look at in the spark burn line is the amount of “hash” it contains. A good cylinder will show a relatively clean line with little hash. A lot of hash, on the other hand, is a product of an ignition or lean misfire.

A vacuum leak into the intake port of the cylinder in question can cause a lack of fuel. Vacuum leaks on individual cylinders commonly occur around intake port gaskets or vacuum hose connections. Insufficient valve lash, a broken piston ring or a leaking cylinder head gasket can cause a partial loss of compression.