In today’s fast-paced import service market, it’s easy to forget the basics of inspecting and repairing MacPherson struts on front suspension systems. But before we get into servicing MacPherson struts, let’s take a look at the design and function of most modern front suspension struts.

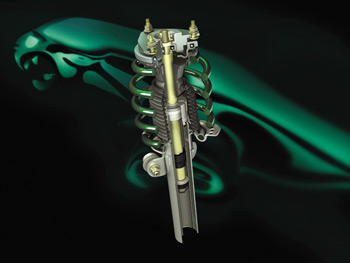

At the most basic level, a MacPherson strut consists of a piston connected to a piston rod that rides in a tube filled with oil. A set of pressure-sensitive, variable-rate valves are built into the piston to control the volume of oil flowing through the piston. These valve assemblies prevent the uncontrolled pitching and rebound that would otherwise occur in the suspension system.

At the most basic level, a MacPherson strut consists of a piston connected to a piston rod that rides in a tube filled with oil. A set of pressure-sensitive, variable-rate valves are built into the piston to control the volume of oil flowing through the piston. These valve assemblies prevent the uncontrolled pitching and rebound that would otherwise occur in the suspension system.

Any hydraulic dampening system is also subject to the hydraulic oil foaming under demanding driving conditions. The oil foams because heat is generated during the dampening process. Heat helps the air contained in the tube to mix with the oil. Foamed hydraulic oil reduces dampening capacity and results in loss of ride control. Oil foaming is suppressed by pressurizing the strut assembly with nitrogen gas.

Engineers also improve ride control by fine-tuning the compression and extension rates of the strut assemblies. In general, struts improve a vehicle’s ride by allowing the strut to compress easier than it extends. Manipulating the extension-compression ratio allows the strut to easily absorb bumps without reducing rebound control. These improvements result in a smoother ride while preserving high-speed stability. On vehicles with electronic ride control, firmness is manipulated electronically to adapt the suspension from normal to high-performance use. In any case, a gradual loss of ride and stability control occurs as these systems wear out or suffer mechanical breakdown.

Suspension Geometry

The MacPherson strut plays a very important role in defining modern suspension geometry. Looking at a strut suspension from the front, it’s easy to see that the lower control arm can swing through a much greater arc without having major effects on the vertical position or camber angle of the wheel. This allows the tire to maintain better contact with the road, even under extreme driving conditions.

In most applications, the for-and-aft position of the lower control arm is maintained by connecting a radius rod from the control arm to the frame. In other, more complex applications, the strut suspension might combine the features of both the MacPherson strut and Short-Long Arm (SLA) suspension systems. In short, the simplicity of the MacPherson strut system makes it more structurally durable and less susceptible to normal wear than the conventional SLA system with its multiplicity of wear points.

Steering Geometry

The MacPherson strut also defines modern steering geometry. The inward tilt of the strut is part of the steering axis inclination (SAI) angle built into the steering knuckle. The backward tilt similarly establishes the caster angle. SAI establishes camber angle during turns and also helps the steering wheel to return to center. Positive caster angle, which is equivalent to the backward tilt of the steering fork in a bicycle, reduces steering wander and helps establish the camber angle and toe-out of the front wheels during a turn.

Strut Geometry Analysis

It’s important to examine the front suspension for bent parts when diagnosing a steering or tire wear-related problem. In some cases, the strut can bend near its connecting point on the steering knuckle or the piston rod itself can bend. Either condition will cause the camber angle, steering axis inclination and, perhaps, the steering radius or Ackerman Effect to change on that wheel.

If suspension damage is suspected, begin by checking the wheel alignment. If, for example, the driver’s-side suspension is well within specification and the passenger’s-side is well out of specification, it’s possible that the lower control arm, radius rod, tie rod, steering knuckle or strut on the passenger’s side might have suffered collision damage. In general, if the camber angle is out of specification and can’t be adjusted, it’s entirely possible that the steering knuckle, as well as the strut, is bent.

If suspension damage is suspected, begin by checking the wheel alignment. If, for example, the driver’s-side suspension is well within specification and the passenger’s-side is well out of specification, it’s possible that the lower control arm, radius rod, tie rod, steering knuckle or strut on the passenger’s side might have suffered collision damage. In general, if the camber angle is out of specification and can’t be adjusted, it’s entirely possible that the steering knuckle, as well as the strut, is bent.

Strut Wear Points

The most important part of any steering and suspension inspection is starting the engine and driving the vehicle into the service bay. When the engine is started, the steering wheel should remain steady and the power steering should smoothly turn from lock-to-lock and return to center as the vehicle accelerates. If the steering turns slightly as the engine is started, the vehicle might have a defective steering gear. If the steering wheel doesn’t return to center, make it a point to inspect the strut support bearings during a strut replacement.

Performing the conventional rebound test is the next step in evaluating wear and tear in a strut assembly. In this test, the front of the vehicle should be bounced by either placing a knee on the front bumper or carefully placing your hands on the front core support or other substantial part of the front body clip.

In general, the suspension should dampen on the first rebound. Remember that some springs and struts, especially on luxury vehicles, feel soft during a rebound test because of their design. If an unusual squeak or knocking noise accompanies the rebound test, locate those noises by using a mechanic’s stethoscope or by placing your fingers on suspension pivot points while a partner bounces the suspension.

If a suspension rattle occurs at low speed on uneven surfaces, the strut’s piston rod bushing or an inner tie rod end might be worn. In some cases, strut rod and other wear can be detected with the suspension unloaded and at full extension. While you’re at it, check the piston rod seal for oil leakage. While some “dry” seepage is normal, the appearance of raw oil around the seal indicates severe leakage.

Last, check suspension height. The vehicle should sit level and meet the manufacturer’s specified height. If the vehicle isn’t level, check for an under-inflated tire or incorrect tire size, sagging spring or a strut assembly that has either lost its gas charge or is sticking due to mechanical failure such as a piston becoming detached from the piston rod.

Strut Replacement

First and foremost, replacing struts isn’t an activity for untrained hands. To prevent serious injury, always use the required equipment and follow the recommended safety procedures.

Strut replacement offers a unique opportunity to inspect the steering and suspension system because all of these related parts exist in an “unloaded” condition with the strut removed. To illustrate, the inner tie rod end connected to the steering rack should demonstrate preload. At the very least, an inner tie rod end shouldn’t rattle when tugged back and forth.

In most cases, outer tie rod ends are preloaded and should be compressed with a pair of water pump pliers to detect excessive wear or inspected during a “dry” steering test with a partner turning the steering wheel. While we’re looking at tie rod ends, we should also check the steering rack boots for oil leakage or ballooning, which indicates leaking steering rack seals.

As for suspension wear, remember that the lower joint is a “follower” joint that is preloaded to maintain precise toe angle alignment. If the strut is removed, inspect the lower control arm and radius rod bushings for looseness. While the lower ball joint and lower control arm and radius rod mounts have only a very slight effect on caster and camber angles, they have a major effect on the toe angle if they allow the wheels to follow ruts in the road. Wear at any lower, unloaded control arm mounting point will cause steering wander and excess tire wear.

Next, because the upper strut bearing supports the weight of the vehicle, it should either be in excellent condition when the strut is replaced or it should be replaced with the strut. Speaking of strut accessories, inspect the condition of the strut rebound pads and strut boots. These parts are vital to the longevity of the strut and should be replaced, if needed.

On a different note, some aftermarket manufacturers are supplying replacement struts as complete assemblies, including a new spring and accessory components. In the short term, these assemblies might be more expensive, but are much less labor-intensive to install. In the long term, they will likely be more profitable and provide better customer satisfaction by addressing most of the issues associated with servicing worn MacPherson struts.