The typical family vacation might start with a trip to your shop to get the oil changed and the vehicle inspected. Taking the extra time to inspect the belts and hoses can make for a trouble-free vacation for your customer and extra revenue for your shop, while a broken belt or burst hose can bring any vacation to an immediate halt at the side of the road.

However, catching a hose or belt before it fails is becoming more difficult as materials improve and engine compartments become more cramped. But, the service opportunities are still there.

Most late-model vehicles will have more than seven hoses to carry coolant from the engine to the radiator, heater core and intake manifold. Each hose has a limited life under the hood. And, belts have a recommended replacement interval that’s listed in the owner’s manual. Missing a deteriorated hose or frayed belt is doing the customer and your shop a disservice.

Groove depth is critical. In the past, cracking and glazing were indicators that a belt needed to be replaced. But, for the majority of serpentine belts today, the replacement specification is determined by the depth of the grooves. When the belt is past the wear specification, the top of the groove bottoms out on the pulleys. The walls of the grooves on the belt are no longer able to grip and drive the accessories.

Look for blue. Sometimes a pulley bearing will heat up to the point that it will discolor the metal and turn blue. If you see this type of discoloration, remove the belt and check the pulley for proper operation.

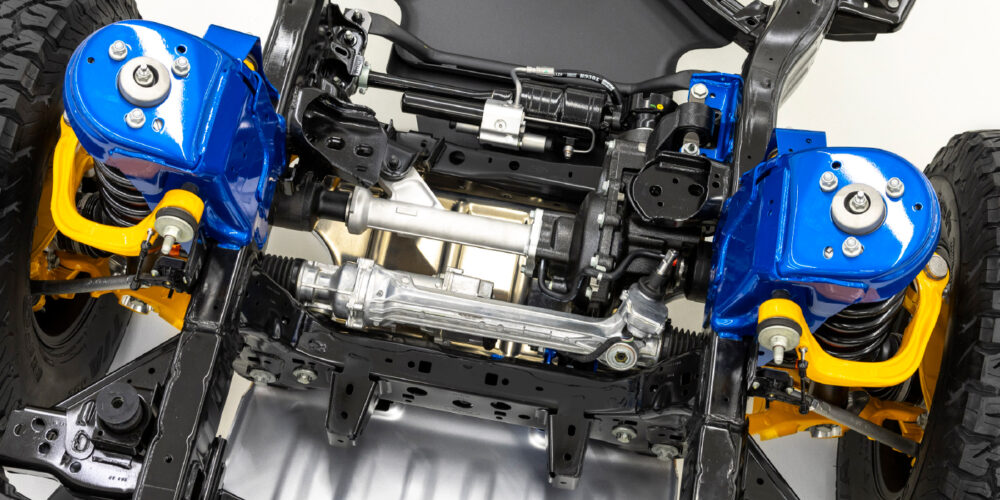

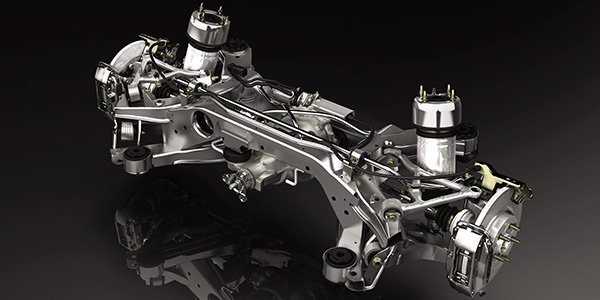

Belt-off inspections. The only way to inspect the total health of an accessory belt drive system is to remove the belt and inspect the idler pulleys for play and movement. If any roughness is felt, the pulley should be replaced.

Inspect the Alternator Decoupler. The alternator decoupler pulley is a wear item. With every pulse of the engine, the decoupler pulley takes a small amount of punishment. To inspect one of these pulleys, you might have to remove the inspection cap/cover to lock the alternator. With the shaft locked, turn the pulley or decoupler with the appropriate tool. If it is an OAP or OWC, the pulley can only be turned in the clockwise direction. If it is an OAD, a counterclockwise turn will reveal a noticeable increase in spring force, and a clockwise turn will have only slight resistance. If these functions are not operational, the OWC, OAP or OAD needs to be replaced.

Squeeze the ends. Coolant hoses will typically have the greatest amount of degradation at the ends of the hose rather than in the middle. The hose will degrade at those points because it is typically where the hose is exposed to heat and oil from the engine. And, with different types of metals in the cooling system, an electrical charge can be generated and carried by the coolant. The electrical current can cause cracks inside the hose around the ends. This is called electrochemical degradation (ECD). Some replacement hose compounds are ECD-resistant. Old coolant with depleted buffers can accelerate ECD. Any signs of bulging, softness or deformation are grounds for recommending hose replacement.

If you see a bulge, replace the hose. Modern hoses are made of ethylene propylene diene monomer (EPDM). On the outside, the surface of EPDM hoses can look like new even after 10 years under the hood due to its resistance to ozone. But, EPDM reacts to oils and solvents that can be found under the hood and in the engine. These substances can cause the hose to lose structural integrity and bulge.

Abrasion on the outside surfaces of hoses and belts can lead to a sudden failure. Even the smallest cut or abraded area can damage the structural fibers. Regarding hoses, make sure all mounting clamps and retaining devices are intact. For belts, even the slightest amount of shoulder wear can destroy them. But, in both cases, try to ascertain the reason why the damage occurred in the first place. It could be as simple as a worn motor mount, or as complex as a belt alignment problem.