The most expensive comeback for a shop is when a car comes back to your shop with the customer complaining of noise after brake service.

First, the noise has to be duplicated. This is time away from the shop on a test drive. Even if there is no noise present, you are obligated to pull the wheels to check the brakes to ensure nothing is wrong. Next, you might remove the caliper and try a little bit of lube or do some cleaning of the slide to eliminate the problem. All of this is done off the clock if you are a flat-rate technician. Even if the technician is hourly, this is lost productivity.

There are no shortcuts to performing a noise-free brake job. It is a difficult job that requires combining the correct parts, knowledge and preparation to make sure that the brakes do not make a noise for more than 20,000 miles or more.

SHIMS

The shim is a critical component when it comes to noise. This may annoy your parts supplier, but order the least expensive and the most expensive pad set for an application so you can look at the differences in the shim.

The shim has to isolate vibrations in the brake pads from being transferred into the caliper and attached brake components. A shim can do this in several ways. The shim can absorb the vibrations by adding an extra layer that absorbs and shifts the frequencies to a range outside of human hearing. Other shims clip to the edges of the pad and create a boundary that prevents the vibration of the pads from being transferred into the caliper. Some shims use both methods to prevent noise.

LUBES

A little of the right brake lubricant can go a long way to eliminating brake noise. Too much of the correct lubricant can cause noise. The wrong lubricant, no matter how or where you apply it, is guaranteed to cause noise. Specialty brake lubricants are designed to hold up to high temperatures without breaking down or being washed away.

When a pad, slide or guide is lubricated at the point where they make contact, the lubricant creates a boundary layer that separates the vibration of one component from exciting another that it is in contact with that has to move when the brakes are applied. If too much lubricant is applied, it can attract dirt and debris that can prevent the pads or caliper from moving freely.

High-quality moly lube should be used on metal-to-metal surfaces, and a high-quality silicone lube should be used on all metal-to-rubber parts. Some silicone lubricants can be used on slides because they are formulated to withstand high pressures and heat.

The key to applying brake lubricants is to put it on the points where the caliper makes contact with the brake pad. On floating caliper brakes, the lubricants should be applied to the ears of the pad, fingers of the caliper and edges of the piston. On opposed-piston calipers, the lubricants should be applied to the outer edges of the pad that make contact with the body of the caliper.

BRAKE PAD SHAPE

One engineering trick is tuning the shape of the friction material. The shape can be made to reduce noise by optimizing the footprint at the rotor and can eliminate hot spots that cause squeaks. OEMs tune the shape of their brake pads to the entire system, which includes elements like overall length, width and shape of the friction on the backing plate.

Following the OEMs’ lead, some aftermarket manufacturers have tuned the shape of their pads to suit older vehicles and the characteristics of their friction material blend. Some replacement brake pads will further optimize the shape of the friction material for noise reduction and to better utilize an improved friction material.

Some shops and technicians still grind chamfers into new brake pads. This was a practice started in the 1970s when the quality of brake pads was not what it is today. Some of the old pads had flashing attached to the edge that needed to be knocked off. Most modern brake pads without chamfers should not be ground to a rounded edge. It is a waste of time, in most cases.

BRAKE HARDWARE

When you pull the hardware from a box of brake pads, it can be tempting to instead clean off the old hardware on the caliper bracket and install the pads. If you avoid using the hardware in the box, you need to use better hardware or better brake pad sets. Oftentimes, inexpensive pads have inexpensive hardware that is not manufactured to the same tolerances as the original hardware.

Hardware should be replaced whenever the pads are replaced. Heating and cooling cycles can weaken springs and anti-rattle clips. Weak hardware parts can result in excessive caliper/pad movement or binding, causing noise and other related problems. Also, this can lead to uneven and premature pad and rotor wear.

GO SOFT

When technicians think of brake hardware, they think springs, clips and slides. But soft parts like dust shields, grommets and bushings need just as much attention. They are available from your parts supplier, and some brake pad manufacturers include them with premium pad sets.

Most floating brake calipers use a rubber or plastic insulator or shim around the mounting bolts of the caliper. This sleeve of soft material loses resiliency over its lifetime. The high-temperature environment of the brakes hastens this process. As materials wear, instead of remaining round they are flattened by the torque from the brakes into an oval shape that can cause excessive caliper movement. This can cause noises like rattles and thumps, even if the brakes are not applied.

Always inspect and replace any dust boots or grommets that protect caliper bolts or slides, if necessary. If the soft parts look fine, clean out all the old lubricant and replace it with application-specific brake lubricant. Chassis or wheel bearing grease will not cut it.

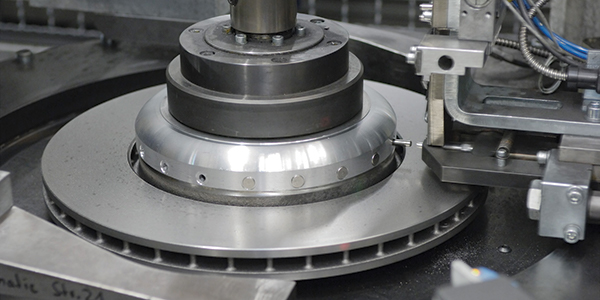

ROTORS

Is one rotor noisier than another? It is a difficult question to answer. Some economy rotors will reduce the amount of iron required to cast a rotor. By changing the mass of the rotor, you could be altering the resonant or natural frequency of the brake rotor and system. This shift can move naturally occurring brake noise into the range of human hearing.

There are very few documented cases of this phenomenon; it is scientifically sound in theory. To prove lighter rotors is noisy, it would require a $400,000 brake dynamometer with an NVH chamber. But, some brake rotor manufacturers are doing this type of testing in the aftermarket.

A non-directional finish can reduce initial break-in noise and create a surface that is more accepting of friction material that becomes the transfer layer.

SERVICE INFORMATION

The secret weapon of the best brake technicians in the war against brake noise is service information. OEMs spend millions of dollars to resolve brake noise problems on vehicles that are under warranty, and many of these solutions apply to vehicles that are out of warranty.

The best source in the service information are the TSBs. OEMs release updates that are typically developed at the dealership level with the help of the engineering department. The solutions rarely involve new brake pad friction formulations. Most solutions involve specific repair procedures that you can apply to the vehicles in your shop.