This month, I want to look at some of the undercar issues we have faced with Nissan vehicles over the years and discuss how to deal with some common issues you may see with them.

We will start with a 2006 Nissan Frontier. This truck was purchased new by a long-time customer and driven very little as the owner was fighting an illness. Unfortunately, he lost the fight and the truck was passed on to his kids’ families to have a truck available when going to Home Depot or when an extra vehicle was needed. As we all know, the downside to that plan is that a vehicle doesn’t like to sit around unused. They try to use it as often as they need it, but more often than not it sits, as evidenced by the 30,000 miles on the odometer.

We got a call one day from the son-in-law asking that we tow the truck in since he didn’t feel safe driving it due to a low brake pedal. My first thought was that a steel brake line had failed, certainly a common problem here in the Northeast where conditions seem perfect to make any steel line rust. As I asked my usual questions — “Is the red brake light on the dash lit?” and, “Have you added any fluid or noticed any under the truck?” — he said no and sheepishly explained that the brakes had started grinding; the neighbor volunteered to do the job; and that it had a couple of rebuilt calipers, pads and rotors, plus a remanufactured master cylinder, but they just couldn’t get a pedal good enough to even drive the truck.

None of us really like to take on a job that someone else has started, but these are very good customers who have been dealing with us for 30 years; so, there was no way we were going to turn them away. As you would expect, our first step was to bleed the brakes as it felt like half of the system wasn’t getting pressure. In our shop, we use the bleed bottle system when manually bleeding the brakes. With the bottle attached to the bleed valve, we slowly stroke the pedal until we see clean fluid with no air in the hose, and we are always careful to close the bleeder on a down stroke. We find this procedure to be the cleanest and most efficient system. Yes, it takes two guys, but you’re less likely to end up with the mess that sometimes occurs with a pressure bleeder.

Well, we had what looked like the expected pressure and volume at each wheel, even though I wasn’t expecting that. From there, I had the tech remove the calipers to confirm that the sliders and pistons on the rebuilt calipers were free and that the sliders were lubricated. I really didn’t suspect a problem, but in our area, stuck and frozen sliders are a common problem. While our Frontier didn’t share the usual symptoms of a good brake pedal with poor braking performance, I figured it was worth a look.

You probably noticed I haven’t mentioned the ABS unit in this discussion. When we do a brake job in our shop, we always open the bleeder valves and install the bleed bottle before the piston is pushed in the bore. We do this to prevent contaminating the ABS unit with the dirty fluid in the calipers. I’m pretty sure the helpful neighbor skipped this step, but the truck wasn’t showing any symptoms that we have seen with a dirty ABS unit.

On vehicles where we have seen with contaminated anti-lock units, they will likely have a low spongy pedal since you can’t move the volume of fluid needed to transfer the air out of the systems.

In this particular case, we were getting good volume and no air. Our experience told us that under normal conditions, these vehicles will have no problem bleeding without activating the ABS system. We did inspect the unit looking for any leakage, but the symptoms didn’t match with a leak under pressure where you have the pedal bleeding down when applied.

DIGGING DEEPER

At this point, we stepped back to regroup and rethink the problem. I called the owner to see if the pedal was this low when the grinding started. He didn’t think so and he had no idea what made the neighbor change the calipers and master cylinder. He also asked that I not call the neighbor.

Before we brought the truck back in the shop, I got in to feel the pedal. To me, it felt like it had too much free play between the pedal and master cylinder. Back in the shop, we were under the dash looking to see if the pushrod between the pedal and booster looked like it had been readjusted or if the locknut came loose and the pushrod backed off. Upon inspection, everything looked tight and there was the expected freeplay between the pedal and booster.

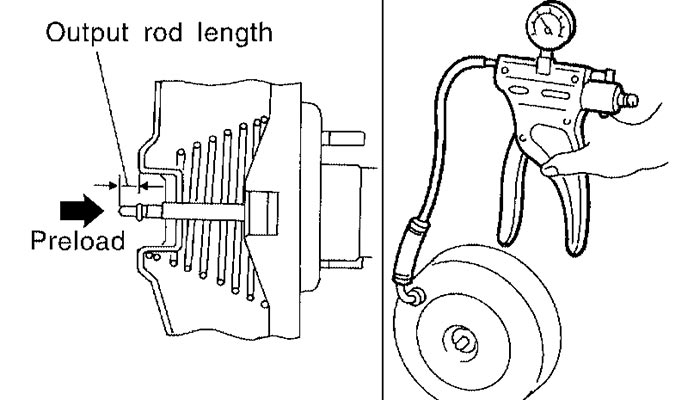

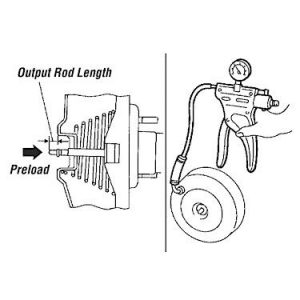

At this point, we removed the master cylinder looking for a problem in this typically trouble-free area. In the past, we have seen some problems where there is too little clearance between the booster output pushrod and the master cylinder that will cause the brakes to overheat or lock up as the brakes and fluid heat up from use. We have never experienced a low brake pedal from this adjustment since there is only a fine adjustment available.

With the master cylinder removed, I was a little surprised not to see an obvious adjustment on the pushrod, only a rod with a tapered end that fits into the master. On other makes, there is usually a screw at the end of the rod with self-locking threads that can be turned to facilitate the adjustment, or a removable tip with a spacer-type adjustment.

Searching our service information, we found a spec on the pushrod with no mention of how to make an adjustment. The tech on the job reported that he found it to be within spec. Out of desperation, we ordered another master since we didn’t have the opportunity to match up the unit when it was replaced. When we got the cylinder, it matched up with the one we had and, going with assumption that we wouldn’t get the wrong unit twice, we had to think we were working with correct master cylinder.

PROCESS OF ELIMINATION

During regroup No. 2, we decided we would source a booster and try it out since we were confident we had exhausted every other possibility. With rebuilt and new units being expensive and a few days away, we decided to try the recyclers. We were comfortable with this decision since brake boosters rarely fail. As soon as we had the unit in hand, we could see the problem immediately — the tip of the booster output pushrod on the original part had somehow broken off.

On closer inspection, you could see where the rod is machined thinner right behind the adjustment tip. The break shortened the rod by about a half inch, leaving what looked like a finished pushrod with no adjustment. With the new booster installed, the pedal was restored and the mystery was solved.

I turned to the tech who measured the output rod and asked how it could have been in spec when the rod was broken. He didn’t have an explanation, so we looked at the procedure together, and he readily admitted he missed or skipped the step where he was to apply vacuum to the booster to fully retract the diaphragm before it was measured. His thinking was he would just hold it in.

After explaining to him how missing that one step had caused us a great deal of wasted time — which of course he already knew — he was apologetic, and I’m sure he’ll be more careful in future. When the booster was removed from the truck, we heard something rattling and found the broken tip lying in the booster.

We’ll never know how or when the tip broke off the rod, but looking at some of the online forums, the only other instance I could find with this issue resulted from the master cylinder being left loose after a fuel filter service. I’m sorry to say we didn’t get any photos at the time, but we do have the diagram showing the output rod adjustment. If there’s a moral or lesson to this story, it’s to be sure all procedures are followed as written. When all was said and done, we had a great pedal and very appreciative customer. It doesn’t get much better than that.

OTHER CONSIDERATIONS

As we look at some of the other things that can cause problems when dealing with Nissan truck brakes, the first is to be careful when pricing brake jobs. Don’t forget that some of the four-wheel-drive vehicles are equipped with captured front rotors that will require removing the hubs. And of course, while you’re in there, it’s a good idea to repack the wheel bearings and replace the seals. More than once, I’ve had to call a customer with an updated estimate once this was realized, which is never a good thing. You should always check the flat-rate book before pricing.

The other issue that is a big problem in areas with icy winters is general corrosion that attacks the undercar systems. I previously mentioned the problems we have with brake lines in my area failing due to rust. This seems to affect some vehicles more than others, but we do keep an eye out for it on the older cars and trucks, paying extra attention where the lines are clipped to the chassis. On some of the older Pathfinders and pickups, we’ve seen the lower control arms fail due to rust and corrosion. If you’re in the rust belt, I’m sure you’re aware, but it doesn’t hurt to tell your techs to keep their eyes open for this condition.

You also can’t forget the need for good work habits when performing brake service. Nissan, like every other carmaker, continues to incorporate driver aids for safety. While having the brakes in top condition was always important, we now have onboard systems like ABS and vehicle stability that rely on the brake system operating as it should. It’s more important than ever to be sure the caliper sliders are cleaned and serviced when pads are replaced; and don’t hesitate to recommend new hardware when needed.

We’ve seen plenty of Nissans with a good brake pedal and poor stopping performance — many, if not all, lead to frozen caliper hardware.

Along with the safety upgrades that these computer-controlled systems offer the car owner come challenges and opportunities for the techs. You have to spend some time and effort keeping yourself educated on these systems as they are released, and you also need the tools to do the job. That means you should have good online service information you can work with to find what you need. It also means having an enhanced scanner that will give you access to the onboard diagnostic capabilities systems.

In an ideal world, we would all have OEM-diagnostic capabilities for every car that we work on along with the knowledge to use them. In the real world, that just isn’t practical. But, we are lucky that there are good aftermarket options available that will give us access to what we need to perform a high-quality repair. One of the most common calls I get from other shops on later-model Nissans involves resetting steering angle sensors after a battery replacement or disconnect. You just can’t service these cars without having the proper equipment. I’m also a firm believer that these capabilities should be provided by the shop. While some of my techs have their own scanners, it’s certainly not expected of them.