Nissan and Infiniti have done such a good job with their anti-lock brake systems that problems could be considered rare, with ABS operation being pretty typical of other models.

On early models, wheel speed sensors send an AC voltage signal to the ABS control module. On later models, active wheel speed sensors change the voltage signal produced by the ABS control module. Active wheel speed sensors are more accurate and work at lower speeds. This is why they are found on most Nissan/Infiniti models after 2012.

The brake light signal tells the unit that the brakes are applied. If the wheel speed sensor signals a brake lockup, the control unit activates solenoid valves in the ABS hydraulic control unit, controlling the pressure to the locking wheel, preventing a loss of traction and keeping the driver in control. Since the system spends most of its time waiting to be called into service, we want to be sure it’s ready when the driver needs it. It monitors itself for faults and will keep the on-dash ABS lamp illuminated if any problems are found.

Pulling Codes

Most of the codes for Nissan ABS and stability control systems are in the ABS module. This module might be under the dash on older models. Newer models integrate it into the hydraulic control unit under the hood. A professional scan tool is recommended when dealing with newer and older Nissan models. Not only can you retrieve codes, but look at data PIDs from the wheel speed sensors, inlet/dump valves and lateral accelerometers. It can also make clearing codes easier, and eliminates the need to jump terminals in the diagnostic connector and counting flash codes.

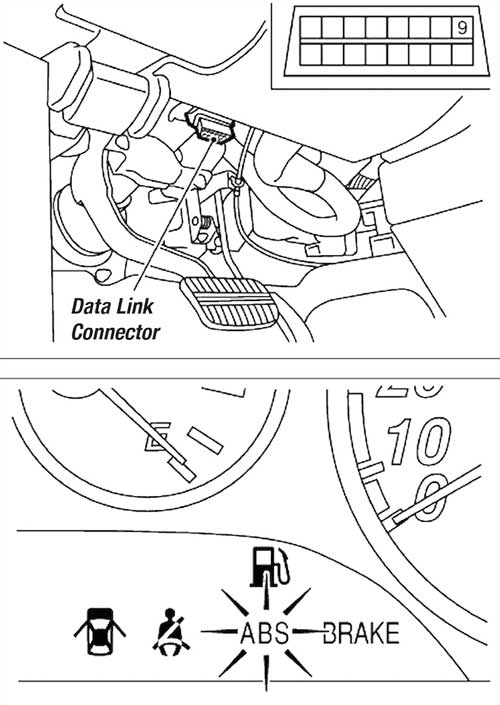

If you’re faced with an older Nissan vehicle with an illuminated ABS lamp, no special tools are required to access codes if you do not have a scan tool. Before retrieving codes, drive the car over 20 mph for at least a minute. I’d even suggest a slightly longer ride that will let you assess overall brake operation.

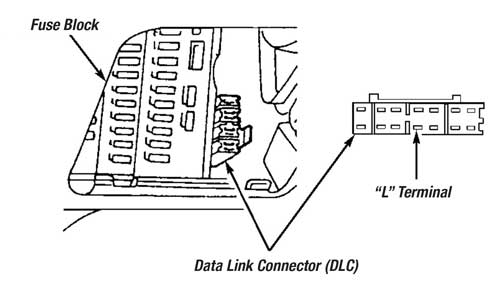

On earlier models, ground terminal 4 in the Nissan diagnostic connector that’s located next to the fuse box. Codes are counted out on the ABS lamp. On some models, it is pin 9 of the datalink connector. This should be performed only if you do not have access to a scan tool with the correct software that can communicate with the ABS. But, always verify that this is possible by looking up the service procedures. It can be extremely risky grounding wires in the diagnostic connector to retrieve codes.

There are two-digit codes with long flashes being tens, followed by short flashes for the ones. For example, one long flash followed by two shorts is 12. When you access the system, the first code you’ll get will be a 12, followed by fault codes if they are stored. Up to three codes will be saved, with the most recent fault being the first displayed. A code 12 will follow the faults. If only a code 12 is found, the system sees no faults.

On pre-2000 Nissan models, codes are accessed using terminal four of the vehicle’s diagnostic connector. The earliest versions have no memory and will display a code only while the ABS lamp is lit. In this case, after the car is driven, don’t turn the key off until the code is retrieved. Using your service information, locate the ABS control unit (in the trunk on Maximas). Count out the code from the LED in the control unit. This system will save only one code. Deal with the code displayed and road-test the car to check for others.

There are too many code definitions to list here, so it will be necessary for you to consult your service information system. As always, the code will send you in the right direction, but it’s up to you to perform the final diagnostic steps to confirm whether the problem is a bad part or a circuit-related issue.

On early cars, the codes are self-clearing, so no ABS lamp means no codes. In some cases, it is required that the codes are cleared. To do this, turn on the key and use the jumper wire you grounded to get the codes. Ground the jumper for one second and disconnect it, then repeat the process twice more in a 12-second period, grounding the jumper for at least one second each time. The ABS lamp will be illuminated during the process, but should go out when completed. Checking for codes and getting only the system’s normal code 12 confirms that the codes have been cleared.

Brake Fluid

ABS has changed the way we service brake systems. The most important change is that the quality of the fluid in the system is critical. It’s no longer acceptable to pull fluid out of the reservoir and simply push in the caliper pistons, moving all of that dirty fluid back through the ABS actuator.

With the small orifices in the ABS unit, it doesn’t take much debris to cause a restriction in the valves that would prevent fluid from returning to the master cylinder when the brakes are released. As the temperature of the fluid increases, the pressure will increase applying the brake, causing the problems we talked about.

I’ve never heard of anyone who has had any success flushing an ABS unit that has been contaminated. Replacement of this expensive unit is the only alternative. It’s an unfortunate situation for the customer, and an even worse one for the shop that did the job. The way to avoid this problem is to always open the bleeders while the pistons are retracted, using a bleeder bottle to catch the fluid. There’s no reason not to get into this habit.

At this point, I wouldn’t think you would consider a brake job complete without bleeding and flushing the system. Although brake fluid changes have always been a recommended service that was often overlooked, it’s something that shouldn’t have been. With the widespread use of ABS and the longevity that these vehicles enjoy, it’s foolish not to at least flush the system when brake service is performed.

We also talked about the importance of good work habits to get the maximum out of the ABS. These procedures are more important than ever. The system works by releasing the brakes to prevent wheel lock-up. And, that requires the basic brake system to be in top condition to function at its best.