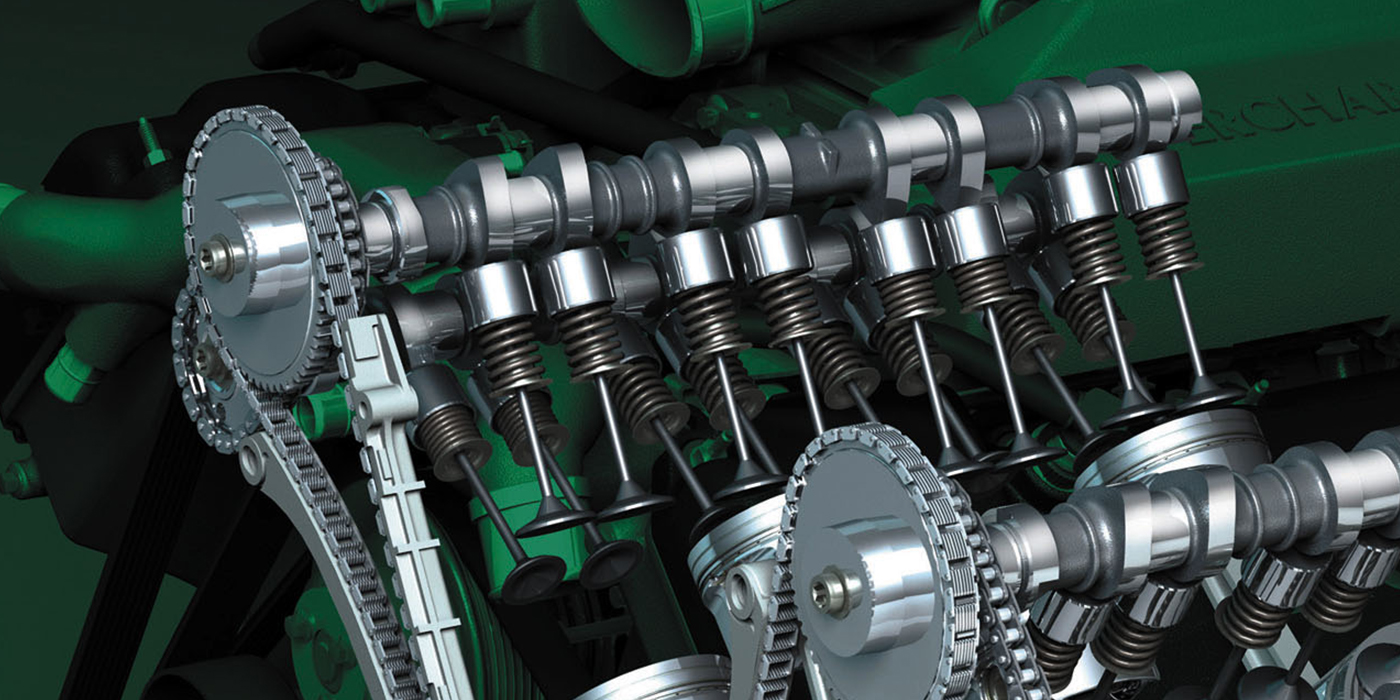

The days of getting away with composition gaskets in extreme combustion situations were back when the deck surfaces on blocks and heads were thick and strong, and the heads were clamped with 5-6 head bolts per cylinder. However, all that changed when carmakers became extremely weight conscious for MPG reasons and they started removing material out of blocks and heads.

The first patent for the MLS gasket was filed in 1970, and the first production vehicle to use an MLS gasket was an Isuzu. This technology burst onto the domestic scene in 1991 when Ford used it on its new 4.6L Modular V8.

Since then, the MLS gasket has become the gasket of choice for OE service and the performance aftermarket. It brings with it several advantages for both camps — they are easy to install because they go on completely dry, require no re-torque after running, require less torque (thereby decreasing bore distortion), are extremely heat resistant and they work well with modern OE torque-to-yield (TTY) fasteners.

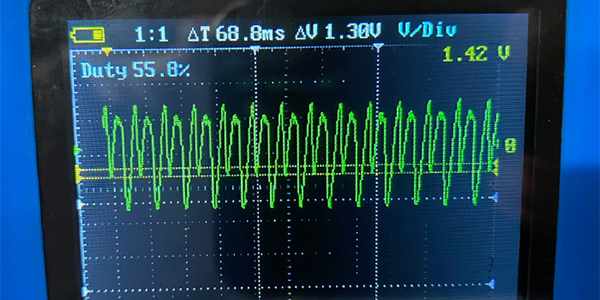

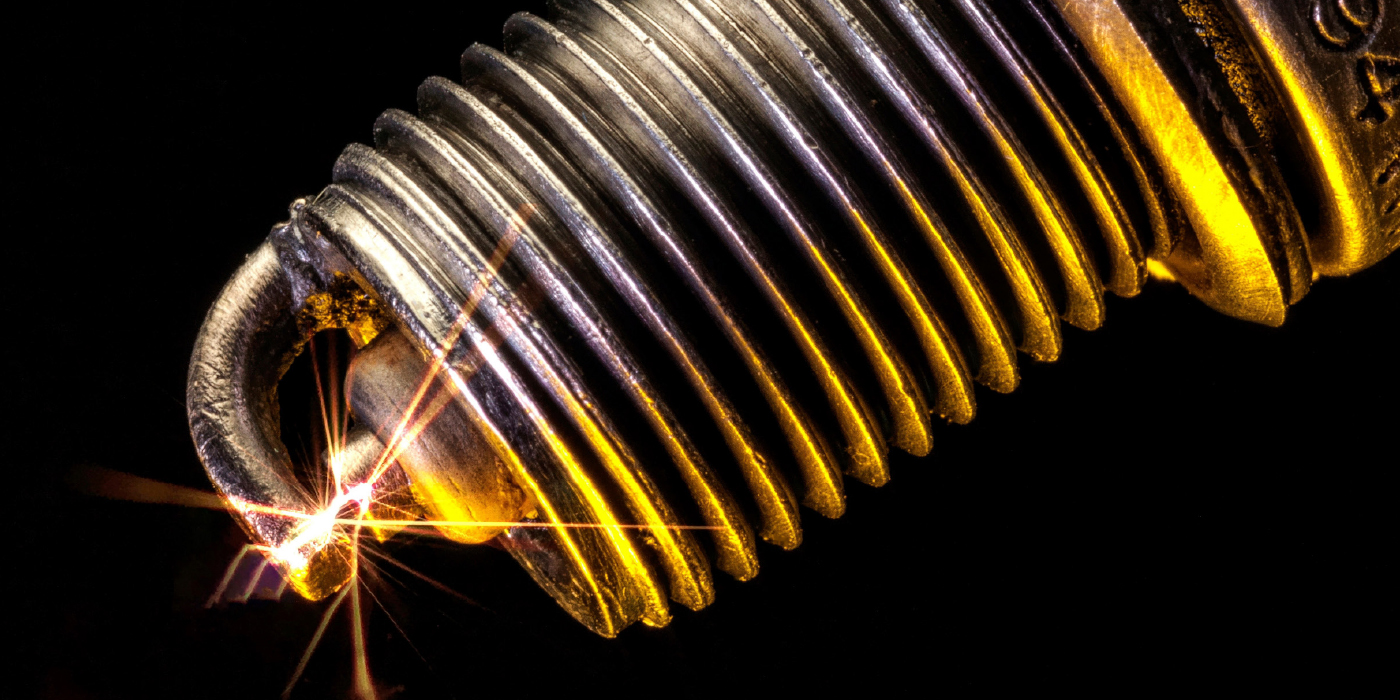

So how does it work? As the name implies, several layers of embossed stainless steel, along with flat layers of steel, are sandwiched together to literally form a “flat spring” that can expand to fill the gap between the head and the block when the head lifts ever so slightly (maybe 0.001˝-0.002˝) during a combustion event. It is coated with a very thin layer of polymer — often it’s a 0.001˝ coating of Viton rubber to seal the liquids. The amazing part of this design is that it retains its “memory” after literally millions of combustion cycles over the life of the engine.

Most MLS head gaskets are three to five layers, depending upon the application. The layers are typically held together with rivets. The differences between the MLS gaskets offered by manufacturers are the grade of stainless steel and the heat-treat of the stainless steel layers after embossing. The size and shape of the “emboss bead” is critical to how the spring works. Embossments are found not only around the combustion chamber, but also around the water and oil passages.

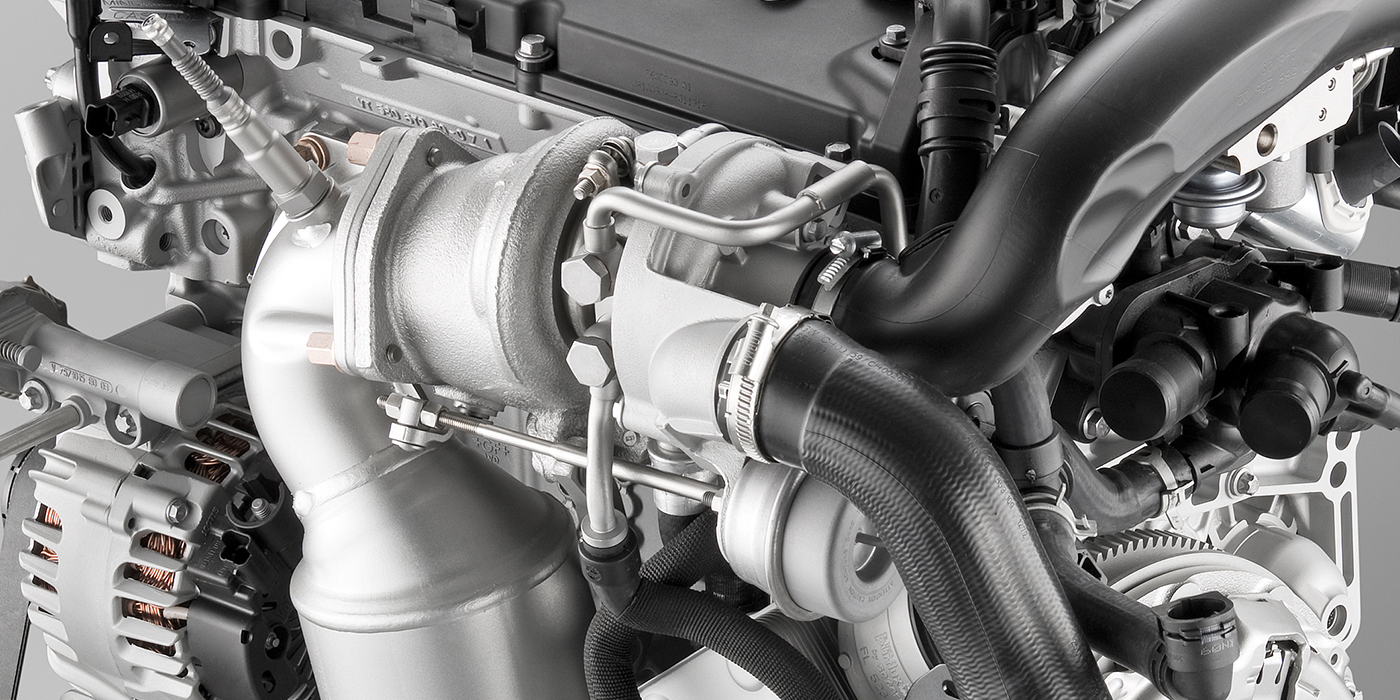

Another feature found in many performance MLS head gaskets, and one that is crucial for nitrous and boosted engines, is the “stopper layer.” The stopper layer accomplishes a couple of important tasks: it provides a very positive seal against combustion pressures, much like a fire ring does in a composition-type gasket. It also keeps the embossed layers from being over-compressed and unable to spring back. Again, each gasket manufacturer has its own take on how to accomplish the stopper layer. Yet, not all MLS gaskets feature a stopper layer.

One of the big changes affecting the performance aftermarket concerning MLS head gaskets is the head/block deck surface finish requirements. While the early OE MLS gaskets required a surface finish of 30 Ra or smoother (roughness average, which is the distance from peak to valley of the machined surface), most gasket makers now can accommodate 40-60 Ra.

Installation

Always install the gaskets dry, unless the gasket manufacturer recommends otherwise. The coating on the outside layers was not intended to interact with additional sealants.

Next, if you are using TTY bolts, never reuse the original bolts because they have already been torqued to yield, and actually pulled a bit into the yield zone by both head liftoff and thermal expansion of the engine components. Otherwise, use quality fasteners, chase the threads in the block and oil the threads to get true torque readings. Be sure to also use a calibrated or certified torque wrench.

Virtually every gasket maker we spoke with strongly recommended against re-using any MLS gasket. The surface sealer could get damaged and the “spring-back” in the gasket may be compromised from engine heat episodes like hot spots in the heads. However, head gaskets used for engine mockup purposes can be reused without a problem.