The press materials from Mercedes-Benz describe the application of the 4MATIC all-wheel-drive (AWD) system as: “as often as necessary, as rarely as possible.”

This means that the system is designed to be transparent to the driver. If you ask owners of a 4MATIC-equipped vehicle about when their AWD system kicked in, they wouldn’t be able to tell you.

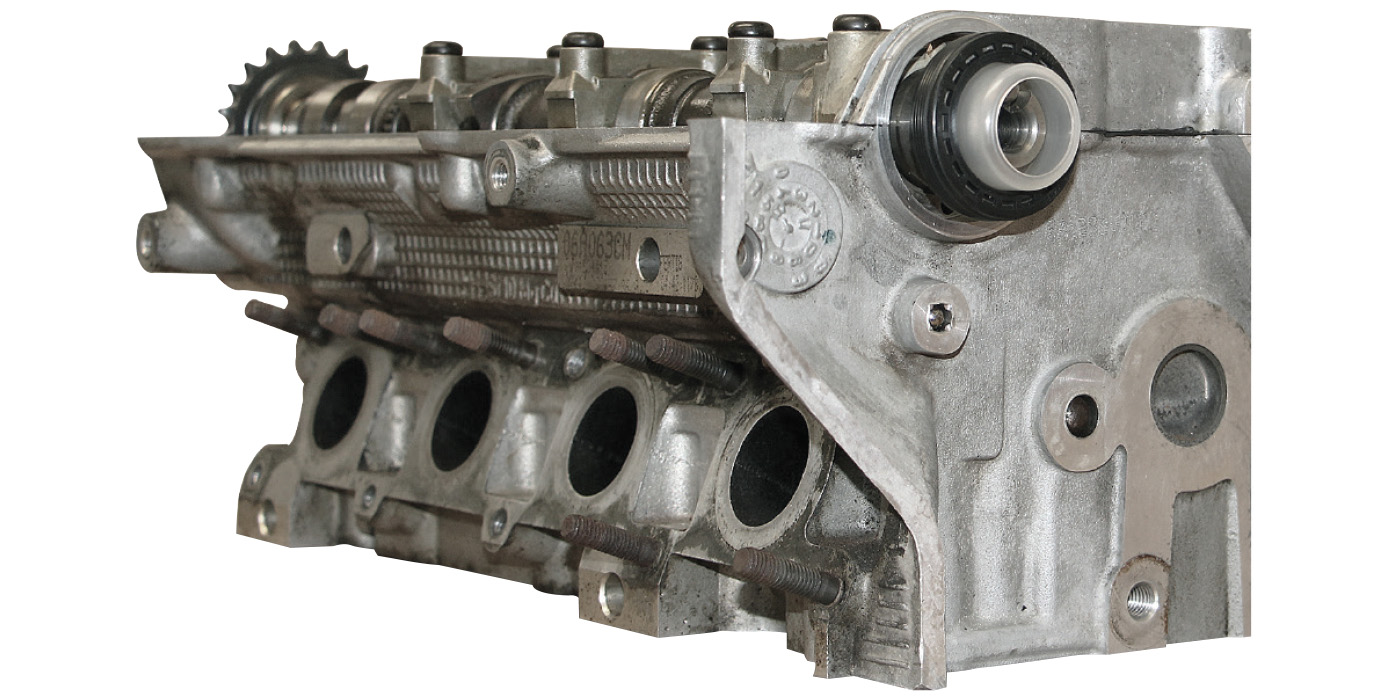

4MATIC, as we know it, came on the market with the 1998 model year on the E-Class and M-Class SUV. In the past 20 years, 4MATIC has become an option on every vehicle Mercedes-Benz sells. The current generation of the 4MATIC system is mechanically bulletproof. But, what can go wrong are the electronics that manage the system, and the seals that keep the fluids inside the transfer case and differentials.

4MATIC is constantly evolving. In the past two decades, there has been a shift in how the power is split, packaged and where the differentials are located.

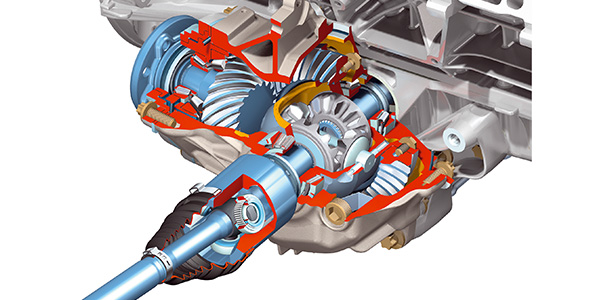

ESP and ETS

All 4MATIC systems use an Electronic Traction System (ETS) and an Electronic Stability Program (ESP) that uses the ABS modulator and brakes to control traction. The hydraulic control module on a 4MATIC has at least 12 valves. With these control channels, the ETS can make a 4MATIC vehicle with open differentials perform like it has limited-slip or locking differentials. Passive or open differentials transfer the power to the wheel(s) that is spinning the fastest, or the wheel that is on the ring-gear side of the differential.

The ETS system uses the brake calipers to apply pressure to the spinning wheel and send power to the opposite side of the differential. This can evenly distribute the power to the rear or front axles under a variety of conditions.

If the car or truck is accelerating hard from a stop, the ETS will apply the brakes independently to prevent slipping. Even if the driver turns off the stability control, the brakes will manage the rear axle, so it performs like a limited-slip differential. If the vehicle is in snow or mud, it can control the traction with the brakes, so the differential acts like it is locked. The corrections are very fast pulsations of the brakes that are undetectable by the driver.

The same system is used to control torque steer on the CLA and other Mercedes-Benz front-wheel-drive platforms.

The ETS system needs the foundation brake system to be in proper working order to function. This means that the pads and rotors must be able to produce enough friction to carry out the 4MATIC corrections. Issues with seized calipers can result in less-than-optimal corrections.

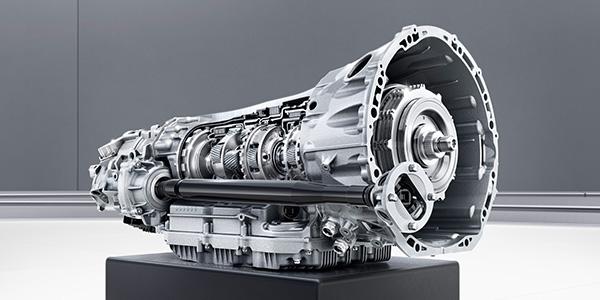

Transfer Cases & Center Differential

4MATIC vehicles have a transfer case mounted at or in the rear of the transmission. The transfer case and transmission do not share the same sump. On the ML-Class and some S-Class models, a chain transfers power to the front wheels. If the fluid is not serviced every 40,000 miles, the chain can wear and stretch. This can cause the chain to make noise as it slaps against the sides of the housing as the driver accelerates and brakes.

On later cars and GL-Class SUVs, the transfer case splits power to the front and rear using helical-cut gears on the output shaft. This achieves better packaging and eliminates a chain that can stretch.

Most 4MATIC systems have fixed power distribution for the front and rear. On most GL- and ML-Class SUVs, it is fixed at 50:50 front and rear. For sedans and coupes, the distribution is typically 40:60 front and rear. More powerful AMG models split the power 33:67 front and rear. Some models have double clutches that can vary power distribution to the front or rear. The clutch sets can also disconnect the front differential for better fuel economy on some models.

On later models, a double-disc clutch locks the torque between the front and rear axles. The clutch pack is permanently preloaded via a plate spring. In the case of spinning wheels on one of the two axles, friction torque is transmitted to the axle spinning more slowly by relative movement of the discs. The transfer case needs the correct fluid for the clutches and planetary gears to work. The fluid in the transfer case is Mercedes-Benz-approved transmission fluid with the correct friction modifiers.

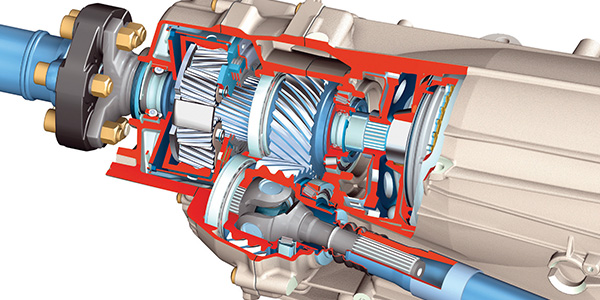

There two transfer case options on 4MATIC M-Class trucks. The most common 4MATIC system is a transfer case with open front, rear and center differentials. First generation M-Class (W163) did have an option for a low range in the transfer case using a planetary gear set, but by the second generation (W164), the low-range transfer case with locking differential in the center and rear were options on the ML550 and AMG ML53.

The transfer case has its own module that controls the operation of the center differential and high- and low-range operation. A separate module performs the locking of the rear differential. It is typically on the Hi-Speed CAN BUS network and needs inputs like throttle position, wheel speeds and even steering angle to operate.

In 2012, for the C-Class and some AMG models, Mercedes-Benz took a different direction with 4MATIC. Instead of using a center differential, power is taken off the rear prop shaft, and control over the torque distribution is done with more advanced front and rear differentials.

The most common customer complaint related to the 4MATIC system is noise. The key to diagnosing these problems is looking and listening. Oftentimes, isolating a problem may require disconnecting the rear driveshaft to take a noisy center driveshaft support bearing out of the equation. Pay special attention to the splined connectors on the output shaft of the transmission and the input shaft of the transfer case. Corrosion and wear can occur between the splines. In some cases, the coupling can wear out completely, and the vehicle will not move.

Leaks & Fluid

Any leaks from the transmission, transfer case or differential should be taken seriously. Damage can occur if the fluid drops to a critical level. The most common leaks can be found around the driveshaft and axle seals.

Sometimes, there will be oil leakage at the seam between the automatic transmission and the transfer case; it can occur around the entire seam. If droplets can be seen, seal the areas with black sealant in the vicinity of the propeller shaft to the front axle transmission. If the problem is a “sweating” leak, sealing must not be carried out, as this is a normal phenomenon inherent in the design of oil-filled systems. If there are any leaks in the differential transfer case, check the vents and breathers. The seals can leak and fail, if the case is over pressurized.

When it comes to fluids, the 4MATIC transfer case uses automatic transmission fluid that meets Mercedes-Benz standards. The same is true for differentials that use 75w-90 hypoid gear lubricant. The standards for the fluids for the entire vehicle can be found at bevo.mercedes-benz.com. They even have an app that can be downloaded from the Apple and Google app stores.

Communication

It takes many modules and sensors talking to each other to make the 4MATIC system work. Many problems and codes you will encounter relate to a loss of communication between the modules. The main culprit is typically due to low voltage in modules caused bad power and grounds and not the module itself.

The ECM, transmission, ABS, transfer case and steering modules are on the CAN bus. If one module is not working, it could mean the multiple modules are missing a critical piece of data.