Jaguar has been using the same suspension design on the XJ, XK and XF/S-Type platforms. The suspension is very similar to those found on Mercedes-Benz and even Tesla models. Most of the load-bearing components are made of aluminum and have hydraulic bushings in strategic locations.

When the suspension is working right, it delivers a great ride and superb handling. When items are worn or damaged, the suspension can annoy the driver with a lot of unpleasant feedback in the seat and steering wheel. Knowing the most common failure and wear items can make for an easy diagnosis.

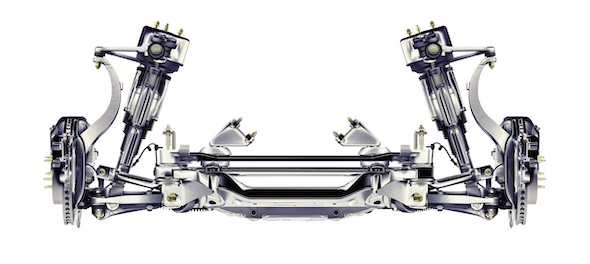

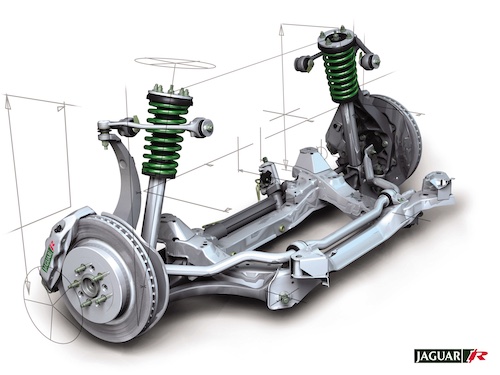

FRONT SUSPENSION

In the front, the suspension setup is a short/long arm design with a tall knuckle. The lower control arm has two parts, which can create some confusion when ordering parts. Most parts catalogs refer to the arms as the lower front control arm and front lower rear control arm. To clear up the confusion, the Jaguar service information calls them a lateral control arm and forward control arm.

The lateral arm extends 90 degrees from the subframe, that has a hole for the ball joint and attachment points for the sway bar links, strut and ride height sensor (the latter applies to XJ models). The components that typically fail are the bushings for the strut and sway bar, and they will cause noise when going over bumps.

It is rare for the large inboard bushing to fail, but it can become more compliant over time. This is a hydraulic bushing and, if it leaks oil, it needs to be replaced. There are two replacement options. First, you can press in new bushings for the strut and sway bar. The other option is to replace the arm.

The forward front lower arm is shaped like a sickle and attaches to the front of the subframe at a 45-degree angle, and the other end connects to the lateral control arm with a ball and socket joint. The ball and socket is the most failure-prone part on the arm. If it is worn out, it can cause changes in the toe and caster. The driver may complain about steering wheel vibrations, clunking noise when going from reverse to drive or pulling brakes. To check for wear, pull up and down on the arm while the vehicle is resting on its wheels. There should be no play at the joint.

The upper control arm is mounted high in the wheel well and is designed to improve the caster trail and steering feel. The inclination of the upper control arm axis provides an anti-dive and anti-squat action during vehicle braking and acceleration. The upper control arm has no adjustments for camber or caster. The most failure-prone component is the ball joint, so always check the ball joint boot for rips or tears. To check for play, grab both sides of the arm and pull up and down.

The knuckle is made of aluminum and holds the lower ball joint and wheel bearing hub unit. The hub unit can be difficult to remove because of corrosion. When you install a new unit, put a light coating of moly lubricant on the surface of the knuckle that makes contact with the hub unit. The next technician will thank you.

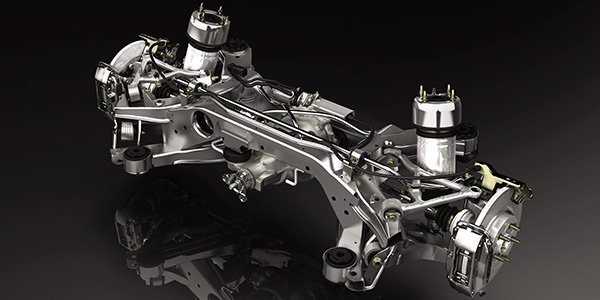

REAR SUSPENSION

The rear suspension uses an upper and lower control arm. The bushings in the arms can wear out and cause inner edge wear on the tires. In extreme cases, worn bushings will cause a “thunk” noise during acceleration and braking. If you notice any of these conditions, recommend replacement of the bushings.

The rear toe links are designed to deform under certain conditions like curb strikes. The rod is made of steel and will bend. If there is even the slightest bend in the rod, replace the assembly.

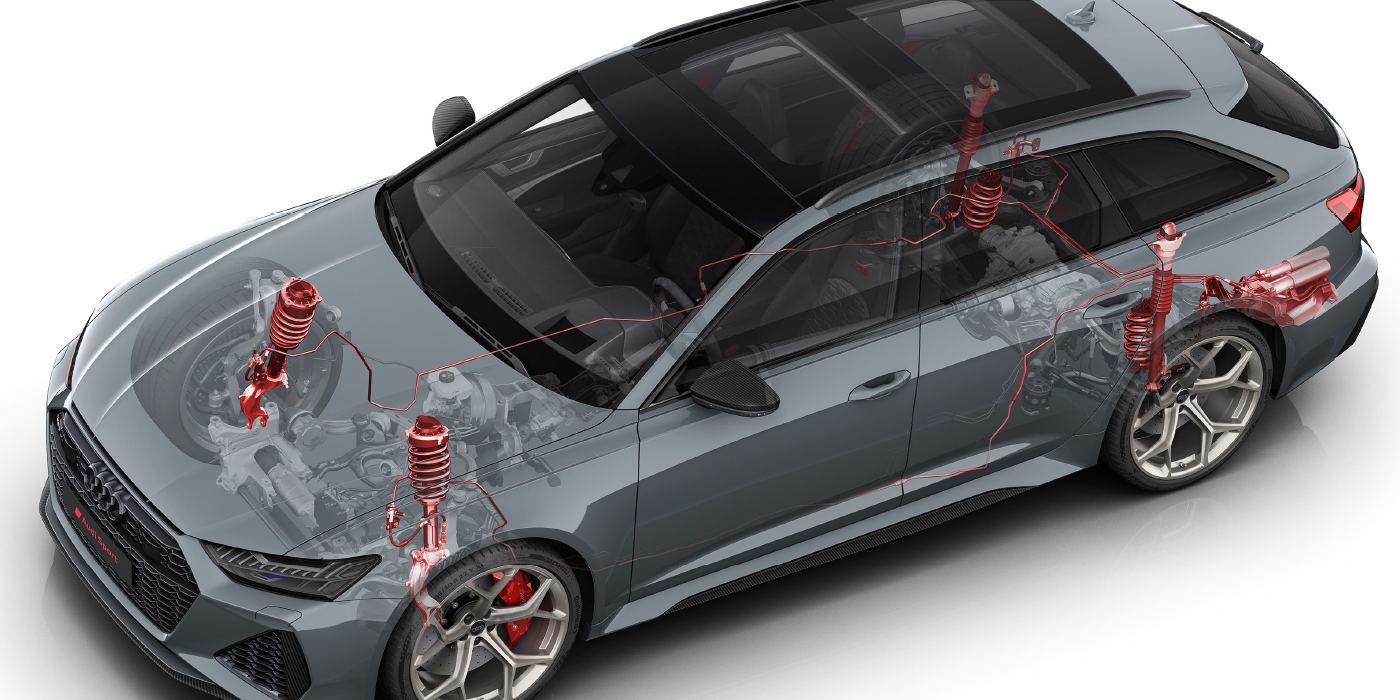

ALUMINUM

While there is a weight savings, the real benefit of aluminum suspension components is their noise- and vibration-dampening properties. Aluminum transmits less road and tire noise to the passenger compartment due to the density of the material.

The most important benefit of aluminum is the reduction in unsprung weight. By reducing the weight that connects to the suspension, handling increases while allowing for a more comfortable ride through the use of lower spring rates and dampener valving. It also allows for heavier brake packages.

In most cases, an aluminum component is as strong as or stronger than steel or cast iron. But what sets aluminum apart is how it fails. Most aluminum suspension components are extruded or forged, and, in some cases, will be heat-treated. If a component has undergone extreme stress, such as a curb strike, the part will most likely crack and break, instead of bending.

If you have a Jaguar in your bay that has been in a crash or has had a curb strike, look for cracks. There are easy-to-use dye kits on the market to help you inspect for issues spot unseen cracks. Never try to weld or heat aluminum suspension components. Aluminum is more heat sensitive than iron or steel. The heat from welding can ruin the temper of a component and make it more brittle.

Always look at the subframe for damage. In the front and rear, the subframes are steel (vs. aluminum) and will deform. Also, check the subframes for corrosion. There have been reports in the salt belt states that the frames have been severely compromised by corrosion.

FASTENERS

The bolt holding the forward control arm to the lateral control arm is a torque-to-yield design. It should not be reused. Jaguar specifies the bolt should be tightened to 45 ft./lbs. and turned 135 degrees.

The bolts that hold the struts to the lateral control arm have a female torx head and are a very specific length so they do not hit the sway bar links. These can be hard to find and will take a lot of force to remove due to the effects of corrosion. Take your time and make sure your torque socket is fully seated before trying to remove it.

The most important tightening procedure is to look up the torque values and procedures. Never guess or take shortcuts when dealing with fasteners on aluminum components.