Although “revolutionary” might be the applicable word for gasoline direct injection (GDI), GDI has been around in one form or another for nearly a century. GDI became prominent during World War II when Germany began using gasoline direct fuel injection in its fighter aircraft to eliminate a lean-out condition that was occurring with conventional carbureted engines during high-speed maneuvers. Although GDI appeared in some post-World War II two-cycle engines and in some high-end performance engines, it didn’t come into its own for passenger car use until around 2008 when high-speed computing and piezoelectric fuel injectors turned GDI into a practical reality.

But, as we know from reading a multitude of service bulletins, the most common problem affecting GDI engines is carbon forming inside the intake ports, on the intake valve face and, particularly, on the finely machined surfaces of the intake valve face and cylinder head valve seat.

To a much lesser extent, some GDI systems might experience premature timing chain wear caused by carbon particles suspended in the engine oil and detonation caused by minute oil droplets self-igniting in the combustion chamber. To better understand these problems, let’s briefly examine some fundamental differences between GDI and port-injected engines.

GDI IN BRIEF

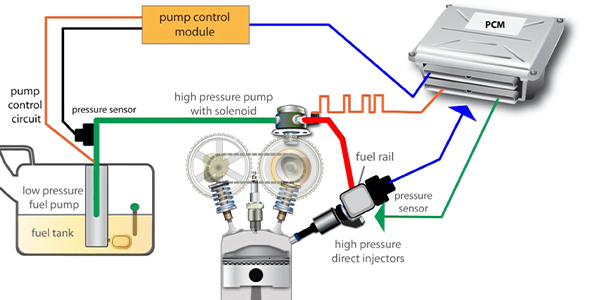

Although GDI is theoretically capable of six or seven different injection modes, variations of the homogenous and stratified-charge modes are used to inject fuel into the cylinder. While conventional fuel injectors are solenoid controlled, many are equipped with piezoelectric fuel injectors that use a stack of silicon chips to open the injector pintle valve. Each chip expands a few thousandths of an inch when exposed to an electric current, which allows fuel to be injected in rapid bursts during each injection cycle. This feature allows the Powertrain Control Module (PCM) to “shape” the burn cycle.

Far from the compression ratios of conventional engines ranging from about 9.5:1 to 10.5:1, compression ratios of non-turbocharged GDI engines typically fall into the 11:1 to 14:1 range that’s typical of many full-bore racing engines. Since GDI cools the combustion chamber by injecting fuel directly into the cylinder, it reduces the tendency to pre-ignite or detonate the intake charge.

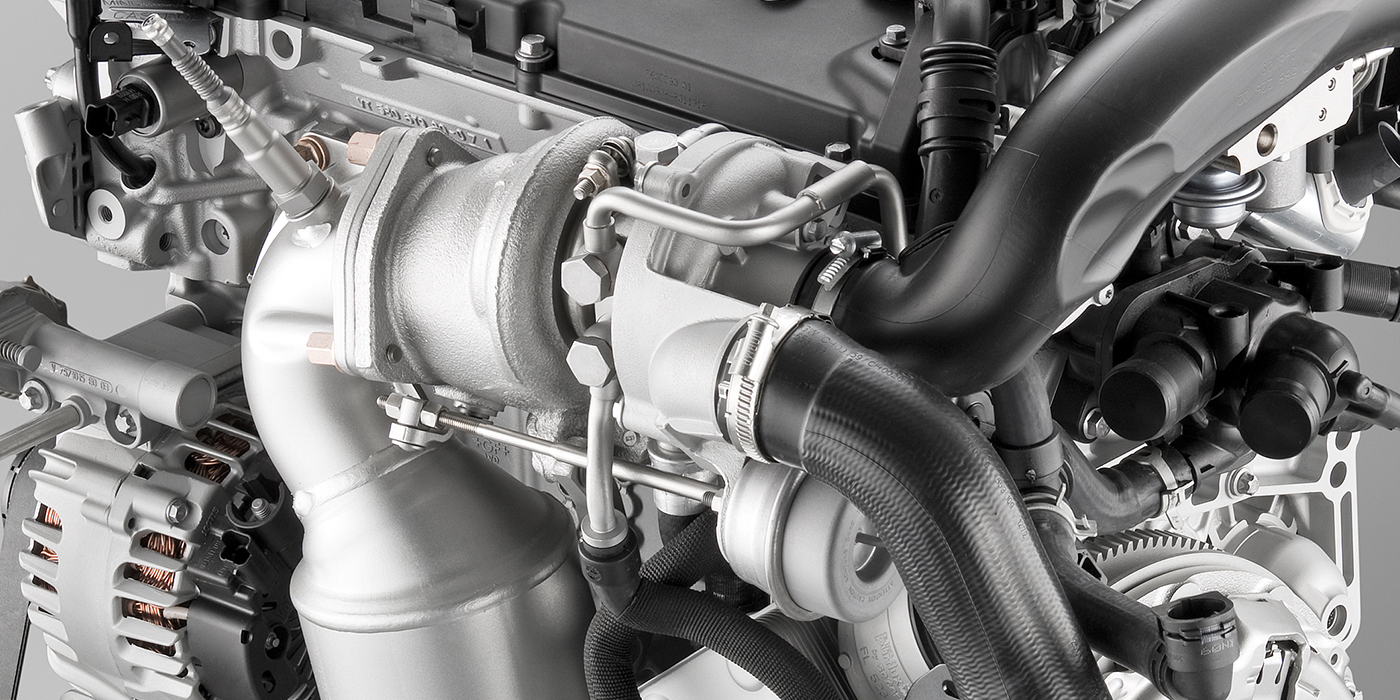

Most GDI engines contain “tumble” valves that cause the intake charge to “swirl” as it enters the cylinder. Once the intake charge enters the cylinder, a contoured piston dome and combustion chamber use this swirling effect to enhance flame propagation. When combined with turbochargers, GDI engines can produce extremely high torque and fuel economy values with relatively small cylinder displacements.

Like conventional modern engines, GDI engines are manufactured with very close piston-to-cylinder wall clearances and tight fits between their pistons and low-tension piston rings to reduce oil ash contamination on air fuel ratio (AFR) sensors and catalytic converters. Tight valve stem-to-guide clearances and improved valve stem seals also reduce oil consumption to a minimum. Reduced crankshaft bearing clearances and micro-polished crankshaft journals allow the use of lower-viscosity engine oils to reduce rotating friction.

Since GDI pistons operate at high combustion temperatures, some GDI engines tap oil jets into their lubrication systems to help cool the undersides of their pistons. GDI engines typically eliminate exhaust gas recirculation (EGR) valves by using variable valve timing (VVT) to admit small amounts of EGR into the cylinders during their intake strokes.

Guarding the Flame

How GDI is Changing Engine Maintenance

You might notice that I’ve used the words “preignition” and “detonation” when discussing GDI combustion principles. Unfortunately, “preignition” and “detonation” are often used interchangeably, which leads to an incorrect understanding of the combustion process. Let me explain:

1. Simply put, preignition occurs before the timed spark, while detonation occurs after the timed spark.

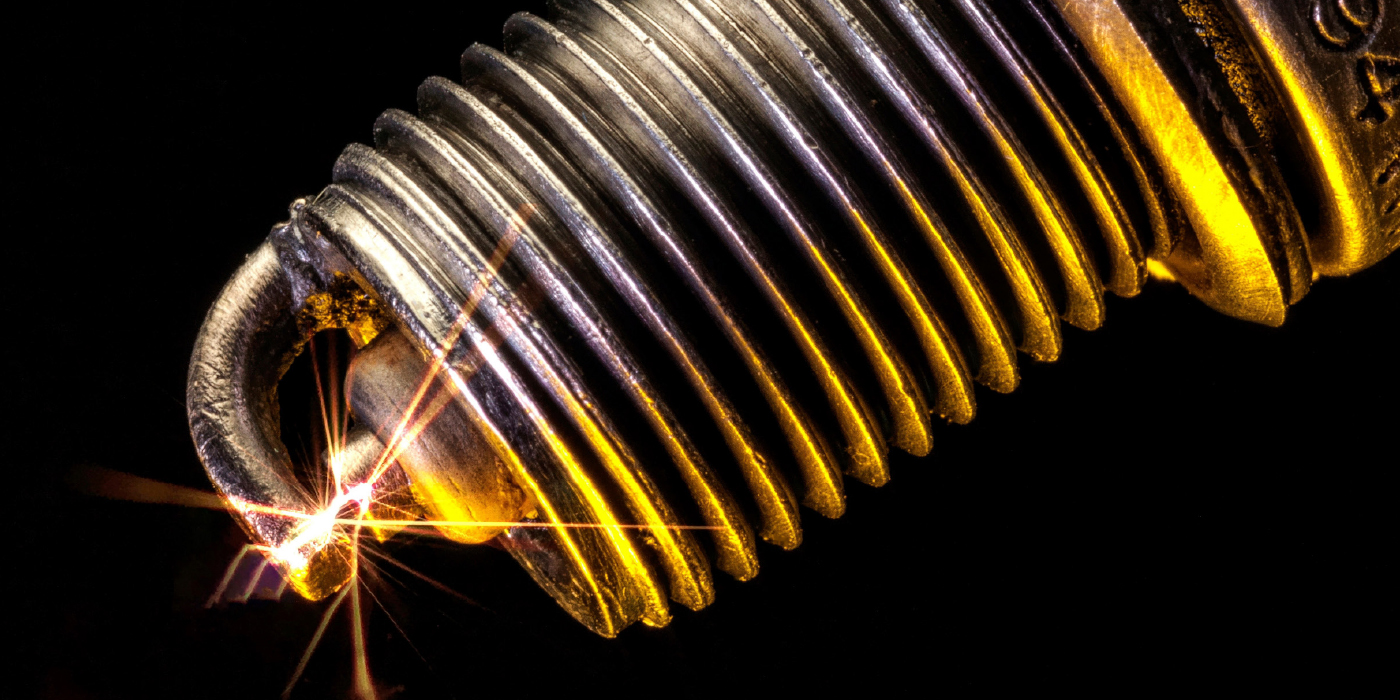

2. A common cause of preignition is a spark plug that’s overheating due to a hotter-than-specified heat range or an insufficient transfer of heat to the cylinder head due to insufficient installation torque.

3. A correctly timed spark in a controlled combustion event might, for example, occur at 35 degrees before top dead center (BTDC) on compression stroke at 5,500 rpm, wide-open throttle.

4. The flame front in a controlled combustion event takes about 1.75 milliseconds to propagate through the intake charge as the piston approaches TDC on compression stroke. During controlled combustion, maximum cylinder pressure develops shortly after top dead center (ATDC).

5. During preignition, an uncontrolled combustion event takes place if, for example, the intake charge self-ignites at 45º BTDC instead of at the timed interval of 35º BTDC. The piston dome becomes overheated when maximum cylinder pressure develops well before TDC and when the piston dome is exposed to heat for an additional 10º of crankshaft rotation. Lean air/fuel ratios combined with advanced spark timing aggravate piston overheating and will eventually melt the piston at its center.

6. Detonation is essentially compression-style ignition occurring after the timed spark due to low-octane gasoline (or oil droplets in the case of GDI) self-igniting at the outer circumference of the combustion chamber.

7. Because the combustion chamber now has two opposing flame fronts, cylinder pressure rapidly spikes, creating a shockwave that typically breaks piston rings and piston ring lands, chips spark plug insulators and creates a “salt and pepper” effect on the spark plug insulator caused by carbon and metal being blasted from the piston’s aluminum surface.

8. Detonation and pre-ignition can occur simultaneously, but that’s another story. While detonation is normally controlled by the engine’s “knock” sensor, the downside is retarded spark timing, which drastically reduces torque output and fuel economy. Fortunately, more comprehensive on-board diagnostics now detect combustion control problems long before a crisis occurs.

GDI LUBRICATION ISSUES

The use of “generic” engine oils can cause premature wear in a GDI engine’s camshaft-driven, high-pressure mechanical fuel pump. While the evidence regarding GDI-induced timing chain wear might be dependent upon design, some GDI operating modes produce a hardened, granular carbon that accelerates timing chain wear. Some GDI engines might also experience low-speed pre-ignition or “pinging” caused by microscopic oil droplets being drawn from the piston rings into the combustion chamber during certain operating modes.

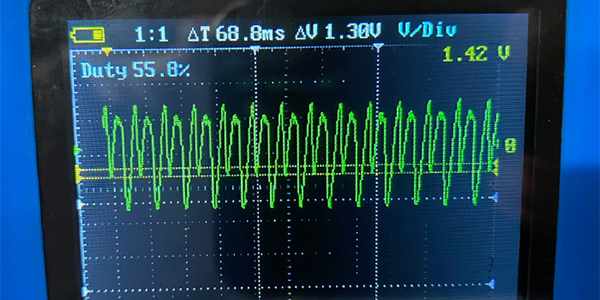

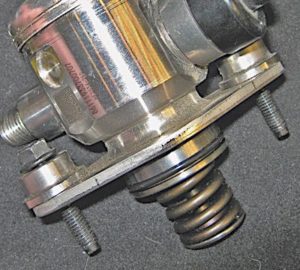

Since oil formulation is a work in progress, I’ll summarize by saying that oils used in GDI, particularly in turbocharged GDI (TGDI) engines, must meet much higher standards than the generic oils intended for conventional, naturally aspirated fuel-injected engines. Oils intended for use in a GDI engine must have enough scuff resistance to protect the camshaft that drives a high-pressure mechanical fuel pump capable of developing well over 2,500 psi of fuel pressure. See Photo 1.

Most important, the oil must keep the engine’s internal parts clean to keep the VVT system working and to prevent the close-tolerance piston rings from sticking.

Last, oils used in GDI engines must have a high flashpoint to help prevent low-speed oil-related preignition and to better lubricate the GDI engine’s hot upper cylinder area. Most GDI engines are now using synthetic-based, lower-viscosity engine oils that offer a greater degree of protection through all climates and all modes of engine operation. See Photo 2.

CARBON ACCUMULATIONS

Since the majority of intake port carbon is caused by the positive crankcase ventilation (PCV) system, it’s imperative that the engine’s piston ring assemblies seal against combustion blow-by. Of course, the end-gaps of the piston rings widen as the cylinders wear, which allows increasing amounts of combustion gases to enter the PCV system. In some cases, a small of amount of EGR might enter the intake port during periods of high intake and exhaust valve overlap.

In any case, GDI engines can accumulate enough intake port carbon to restrict or disturb the carefully engineered flow of the intake charge into the cylinder. The intake valve face and seat might also accumulate enough carbon to create minor compression leakages that lead to a low-speed cylinder misfire and an illuminated malfunction indicator light (MIL).

CARBON SOLUTIONS

In my experience, driving conditions are important. For example, I’m not seeing many carbon formation problems on GDI engines in our hard-working rural mountain area. On the other hand, intake carbon problems occur more frequently where low-speed, stop-and-go driving is common. The most tried-and-true method of removing heavy intake deposits is to remove the intake manifold and air-blast the intake port with crushed walnut shell media. But the blasting method is very time consuming and won’t prevent carbon from re-forming in the intake port.

Some aftermarket suppliers have introduced aerosol, misting-type carbon removers that are designed to remove moderate intake port carbon on GDI engines. I’ve tried one brand and found that it does indeed dissolve small amounts of hardened carbon. But remember: Connecting rods can easily be bent when using conventional intake cleaning methods to remove intake port carbon. In these cases, the tumble valve accumulates liquid solvent inside the intake manifold runner and dumps it into the cylinder when the engine is accelerated.

When servicing a GDI engine, “cheap” isn’t an option. The best long-term strategy to prevent intake port carbon from forming is to use more expensive, OE-approved engine oils and high-detergent, tier-one gasolines available from major suppliers. In areas where low-speed driving is a problem, routine preventive maintenance that includes a periodic carbon removal procedure will help prevent misfires caused by intake carbon formations.

Last, but not least, some manufacturers are now incorporating a small port injector into the intake manifold for the sole purpose of keeping the intake valve seats clean. As of this writing, I don’t fully understand the operating strategies involved, but it does sound like a home run when searching for this month’s Diagnostic Solution.