For political and economic reasons, the use of ethanol gasoline in the U.S. has always been controversial. To better explain, the U.S. and Brazil are the world’s leading producers of ethanol-blended gasolines. In Brazil, ethanol is an economic issue because the country’s hot equatorial climate is very hospitable to the rapid growth of biomass, which is cheap organic waste that can be made to produce ethanol. Brazil subsequently produces enough cane sugar biomass to help fuel most of its national vehicle fleet on E-25, which is a 25% ethanol, 75% gasoline blend.

But in the U.S., and under the amended Clean Air Act of 1990, ethanol as a gasoline additive is an environmental issue because ethanol gasoline can be used to reduce tailpipe emissions in localized emissions non-attainment areas like mile-high Denver, CO. Cheap biomass is generally created by growing large quantities of low-grade corn in the nation’s mid-western states.

Today, the readily available E-10 comprises nearly all gasoline sales in Colorado and other states. E85, on the other hand, varies with local availability.

THE INFAMOUS P0171/174

Most diagnostic problems associated with ethanol fuels begin with P0171 (cylinder bank one) and P0174 (cylinder bank two) diagnostic trouble codes (DTCs) indicating lean air/fuel ratios (AFRs). On a hypothetical basis, let’s use a 2011 Nissan Altima with a P0171 DTC as an example of how ethanol-related diagnostic cases might develop. This vehicle is low on power and doesn’t start or run well when cold. Several vacuum leaks have been repaired and the mass air flow (MAF) and air/fuel ratio sensor have been replaced. The fuel gauge indicates that fuel level is 33%. So, where do we begin? See photo 1.

ETHANOL CHEMISTRY

Let’s begin by noting that pump gasoline is blended for different seasons, climates and altitudes. Slightly different percentages and ratios might also result when a laboratory-grade gasoline is used for emissions testing purposes. So, the percentages and ratios used on the next page might differ from those quoted in other sources.

But for our purposes, non-ethanol gasoline requires a 14.7:1 AFR to achieve stoichiometric, while E10, or 10% ethanol gasoline, requires a 14.0:1 AFR to achieve stoichiometric, which is an optimal air/fuel ratio. On the other hand, E85 or 85% ethanol gasoline requires approximately a 9.85:1 AFR to achieve stoichiometric. While E10 doesn’t harm most 1980-and-newer fuel systems, E85 requires fuel system components that are resistant to high concentrations of ethanol. Ethanol also absorbs water, which can cause corrosion problems in high-humidity climates.

E85 also has a lower cold volatility rating than non-ethanol gasoline, which can cause cold-starting complaints in colder climates. Since the energy content of E85 ethanol is considerably less than gasoline, fuel flow must be increased by about 37% using higher-capacity fuel pumps and fuel injectors to avoid a lean air/fuel ratio condition.

Non-ethanol gasoline contains about 114,000 British Thermal Units (BTUs) of energy, while E85 contains about 84,000 BTUs of energy. E10 generally reduces fuel economy in the 2% to 3% range under laboratory conditions.

While E85 will increase performance approximately 4%, fuel economy can decrease up to 33% due to the lower energy content of ethanol. On the other hand, E85 is much cheaper at the pump. Whatever our opinions, ethanol isn’t going away soon because flex-fuel vehicles (FFV) are now targeted to become 50% of current new-vehicle production.

FFV HARDWARE

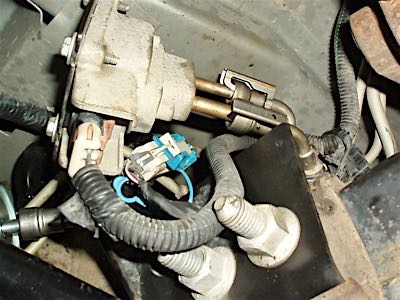

During the late 1990s, import auto manufacturers began designing flex-fuel vehicles to use E85 gasoline. Unless pure ethanol or another alcohol variant is introduced into the fuel tank, ethanol content should range between 10% and 85%. While we’re not going to dwell on the technology, some early FFVs used a frame-mounted inline ethanol sensor to measure the gasoline’s ethanol content to help the ECM achieve an appropriate AFR. When the ethanol sensor failed, it would usually set vehicle-specific trouble codes. See photo 2.

As technology advanced past model year 2000, wide-band oxygen sensors came into general use. Wide-band sensors can measure a far wider range of AFRs than conventional narrow-band zirconia oxygen sensors, which could differentiate from only about 14:1 AFR to about 15:1 AFR. Larger-capacity fuel injectors are also required to accurately meter larger volumes of fuel required by ethanol delivery systems. While slightly larger evaporative canisters and other minor hardware items are also required to utilize ethanol, accurately measuring ethanol content has become more of a software and programming issue on modern FFV systems.

Further improvements include gasoline direct fuel injection (GDI) and variable valve timing, both of which can utilize compression ratios up to approximately 14:1 (as opposed to the 10:1 and lower compression ratios used in conventional engines). Since E85 ethanol gasoline has a much higher octane rating than non-ethanol pump gasoline, E85 adapts very well to high compression ratios. Increased computer capacity is also required to operate GDI/VVT engines and to process ethanol calculations.

MONITORING ETHANOL CONTENT

Remember that flex-fuel monitoring is basically a software operation. Since most refueling events mix various blends of E10 and E85 gasolines, the ECM must “relearn” previously learned adaptives in the form of open-loop fuel injector pulse widths and closed-loop fuel trims. These adaptives are used for optimal open-loop, cold-start and closed-loop driveability performance when operating at different altitudes and temperatures.

The most common flex-fuel strategy is to compare before-and-after fuel levels from a fueling event to indicate possible changes in ethanol content. To briefly illustrate this “relearning” mode, most vehicles are refueled with the ignition off. When the ignition is turned on and the ECM senses a specified minimum fuel level change, the ECM initiates this relearning process. That said, be aware that the abbreviation of the term “percentage of methanol” (PM) used in some service information or scan tool data indicates the percentage of ethanol.

An FFV’s operating strategies for resetting fuel trims and other data after refueling obviously will vary with vehicle application. The ECM strategy for one manufacturer might first classify the new fuel as non-ethanol or E85 ethanol gasoline. But that will happen only if the old and new fuels fall within a specified range of perhaps 5%-10% ethanol content with each other.

If the PM of the old and new fuels falls outside this specified range, the new fuel might remain unclassified until the next refill. Until the new fuel is classified, the long-term fuel trim might not accurately indicate a lean or rich condition on some vehicles.

Once the engine is running in the closed-loop mode, the air/fuel ratio sensors will provide the input data needed for the ECM to achieve stoichiometric, while the ethanol monitor will eventually reset fuel trim parameters to prevent setting a P0171/P0174 DTC.

While this summary of one manufacturer’s operating strategy represents only a brief look at how the ECM processes data when it begins the relearning process, it does indicate the potential complexity of diagnosing the P0171 DTC on our 2011 Nissan Altima. Our diagnostic clue is that the Nissan’s fuel gauge indicates 33% full, which could be heavy on E85 gasoline. Topping off with E10 solved the problem on our Nissan, which is a non-flex fuel vehicle. Check our sidebar for more diagnostic clues.

While FFV service information can range between plentiful to non-existent, it pays to consult the import manufacturer’s database before diagnosing a suspected ethanol-related engine performance problem. If the import manufacturer’s service information is on the scarce side, the service tips listed below might help you determine if you have an ethanol-related performance problem.