A conventional thermostat is like a carburetor in that they only respond to throttle and engine vacuum signals. A conventional thermostat can only respond to changes in temperature caused by heat from the engine and cooling from the radiator.

An electronic thermostat can preemptively control the temperature the same way the fuel injection system can control the stoichiometric ratio in the combustion chamber by changing the pulse width of the fuel injector.

By being able to control the temperature of the coolant, the engine management system can optimize engine performance so leaner combustion events can take place and cold start periods are minimized. It does this by minimizing sudden surges of cold coolant from the radiator side of the cooling system. This helps to keep a more consistent temperature for the engine. Most of all, this minimizes the sudden need to make the fuel mixture richer because there is a sudden drop in block temperature.

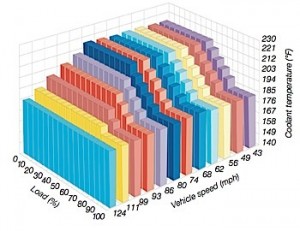

These new electronic thermostats can also help prevent extreme heating conditions because they can be opened when certain conditions are detected. Factors like engine load, ambient temperature, engine RPM and ignition time can influence the position of the thermostat. These inputs can be configured into a “map” that can optimize engine performance. This means that the thermostat can have a completely different setting position if the vehicle is just cruising along vs. doing a wide-open-throttle launch.

This type of thermostat can be found on the following:

– Audi

– BMW

– Ford

– GM

– Ford

– Volvo

– VW

Conventional Failure Mode

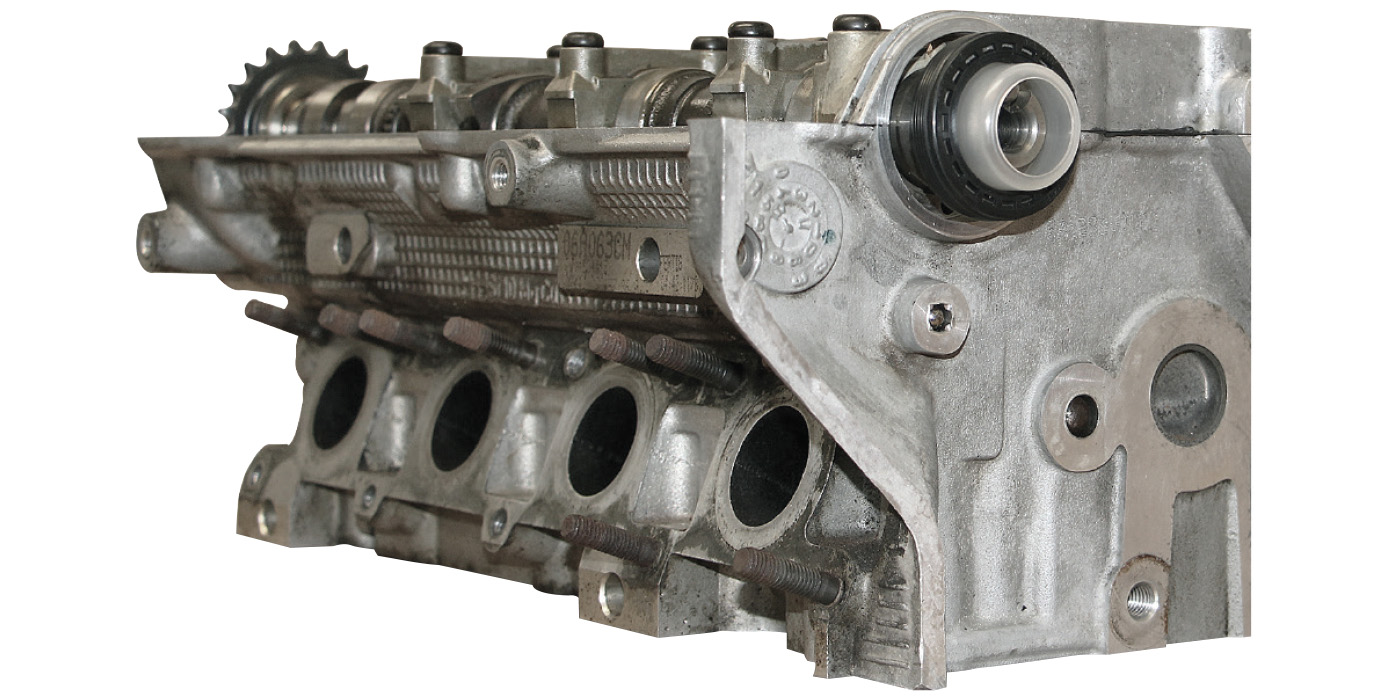

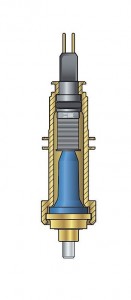

Most thermostats use wax inside a brass chamber that expands when it is heated. When it expands, it pushes on a pin or piston that is connected to the plate and spring. Movement of the plate allows coolant to flow from the bypass coolant circuit to the circuit that has the radiator. This system has been in operation since the 1950s.

For the wax to work and the thermostat to open, several things must happen. First, the brass chamber that contains the wax must be submerged in the coolant. Air does not transfer heat like coolant does. This means that all the air is bled from the system. This is also why most thermostats have a “jiggle pin” that allows a small amount of coolant and air bubbles to pass so the wax is submerged. Second, in order for the engine to warm up in a uniform manner, coolant must freely circulate past the wax pellet. To accomplish this, most engines have a coolant “bypass” between the water pump and intake manifold to allow coolant to circulate with the thermostat closed.

In some cases, manufacturers may use the vehicle’s heater hoses and heater core to circulate water through the engine block with the thermostat closed.

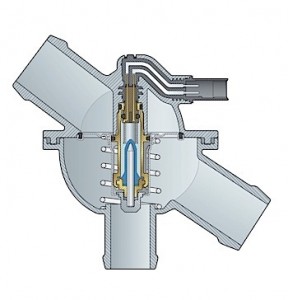

An electrically controlled thermostat still uses expanding wax, but it controls the temperature of the wax. To do this, it uses a heater coil surrounding the wax capsule — no fancy stepper motors or plungers.

Overheating can damage the wax in the thermostat. This is why it is always a good practice to replace the thermostat on a vehicle after it has overheated. This is also true on electric thermostats because the overheating could damage the heating coils.

Most thermostats are designed to fail in the open position. This prevents catastrophic overheating. But, it also means that the engine will have a longer warm-up period, which could damage the engine. In the case of the electronically controlled thermostat, the engine management system will recognize this failure and set a code due to the inability to change the coolant temperature.

Both types of thermostats can suffer mechanical damage that prevents them from closing and opening. This can include damage to the springs and straps on the body of the thermostat. Also, debris and corrosion can prevent a thermostat from working.

When the heater or driver circuit fails on an electronically controlled thermostat, the thermostat becomes a conventional thermostat and will not cause the engine to overheat. However, the engine will know it has failed and will generate a code.

Identification

The majority of vehicles with an electronically controlled thermostat have a thermostat module, housing or unit. On the side of the thermostat housing will be a connector that you might assume is a temperature sensor. Like a coolant temperature sensor, it will have a two-wire connector.

The majority of vehicles with an electronically controlled thermostat have a thermostat module, housing or unit. On the side of the thermostat housing will be a connector that you might assume is a temperature sensor. Like a coolant temperature sensor, it will have a two-wire connector.

One wire will be a ground and the other will supply voltage to the heating coil. The voltage to the coil will be regulated by the engine management system. Some systems will turn the voltage on or off as needed. Some systems will use a pulse-width modulated signal to control the temperature like a heater on an oxygen sensor.

Codes

On these systems, there are two ways the engine management module knows there is a problem. The engine module is able to determine if there is a short or open like a heater circuit for an oxygen sensor. It does this through measuring voltage drops to determine if the circuit and component are functioning normally.

If the heater circuit is no longer able to control wax, the lack of change can be detected by the coolant temperature sensors on the block, head and radiator. When the engine management module detects this condition, it will set a code.

When the heater circuit fails, most of the time it will create an open circuit. In some cases, the opening might not occur until the engine is warm. Keep this in mind if you clear a thermostat or coolant-temperature-related code.

Testing

With the average electronically controlled thermostat module costing more than $130, it is critical to test the component and circuit before installing a new part.

The first component to check is the circuit. If the system has a code for an open or short in the circuit, clear the code. If the code comes back immediately, you have confirmed the problem, unless the problem is in the heater coil or the circuit on the vehicle. You can determine if the coil is bad by measuring the resistance in the component. If it is open, the heating coil is damaged. If it is not open, measure the resistance and check the specification in the service information.

You can also use an amp clamp to determine if the engine management system is sending voltage to the component. These systems can either be ground or positive voltage switched. You can also see the switching if you have a scan tool that can watch this data. Some scan tools can even bidirectionally control the heater circuit.

VW has a testing method for some vehicles that is very similar to the pot of boiling water test to see if the thermostat is opening. It involves sending battery voltage to the thermostat while it is submerged in hot water. They warn that if the heater is not submerged during the test, it could be damaged. This method will not work on all units when the thermostat is buried in the housing.

If the cooling fan temperature sensor is located in the radiator, a partially opened thermostat may cause the sensor to not activate the fan relay due to reduced coolant flow past the sensor. Moreover, if the vehicle overheats on hot days or during long climbs in mountainous areas, a partially opened thermostat may be to blame.

The Future

The electronically controlled thermostat is being used on more domestic and import vehicles. This technology is also being used on oil coolers and in HVAC systems. On future engines, there will be multiple heated thermostats to control temperatures in the head and block.

This thermostat’s advantage is that when it fails, it doesn’t leave the customer stranded. It just leaves them with a check engine light and a less efficient vehicle.