Considering that roughly 1,500 or more different vehicle models are introduced into our domestic market each year, it’s becoming more difficult to predict how a Powertrain Control Module (PCM) will utilize data from a particular sensor or detect an out-of-range sensor in any single vehicle platform.  The engine coolant temperature (ECT) sensor provides a good illustration of how many on-board diagnostic strategies have changed. Keeping in mind that an of out-of-range ECT sensor can, among other things, affect the PCM’s fuel and spark mapping, variable camshaft timing, transmission, radiator cooling fan and evaporative emissions functions, it’s important to develop an awareness of how the PCM self-diagnoses the ECT circuit and how the ECT data is integrated into a vehicle’s operating strategy.

The engine coolant temperature (ECT) sensor provides a good illustration of how many on-board diagnostic strategies have changed. Keeping in mind that an of out-of-range ECT sensor can, among other things, affect the PCM’s fuel and spark mapping, variable camshaft timing, transmission, radiator cooling fan and evaporative emissions functions, it’s important to develop an awareness of how the PCM self-diagnoses the ECT circuit and how the ECT data is integrated into a vehicle’s operating strategy.

Much of any on-board diagnostic strategy depends upon the computing capacity of the PCM. Most pre-1996 OBD I and many early post-OBD II Engine Control Modules (ECMs) and PCMs had only enough computing capacity to detect hard or intermittent circuit voltage faults.

In many cases, early ECMs didn’t have enough capacity to rationalize the performance of the ECT sensor with other data inputs. So, in some applications, it’s possible that an out-of-range sensor can affect the operation of many OBD II test monitors and the operation of many vehicle components without setting a trouble code. In passing, remember that the ECT input is part of the freeze-frame data that accompanies most diagnostic trouble codes.

In many cases, early ECMs didn’t have enough capacity to rationalize the performance of the ECT sensor with other data inputs. So, in some applications, it’s possible that an out-of-range sensor can affect the operation of many OBD II test monitors and the operation of many vehicle components without setting a trouble code. In passing, remember that the ECT input is part of the freeze-frame data that accompanies most diagnostic trouble codes.

OPERATING STRATEGIES

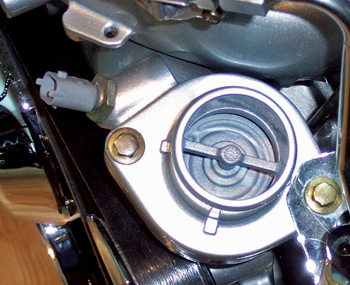

Most modern automotive ECT and intake air temperature (IAT) sensors are generally two-wire, “negative temperature coefficient” (NTC) thermistors in which the electrical resistance of the ECT and IAT sensors decreases as temperatures increase. See Diagrams 1 and 2.

Most modern automotive ECT and intake air temperature (IAT) sensors are generally two-wire, “negative temperature coefficient” (NTC) thermistors in which the electrical resistance of the ECT and IAT sensors decreases as temperatures increase. See Diagrams 1 and 2.

At the extremes, an open-circuit ECT should indicate a scan tool data of approximately -40°F coolant temperature, since the PCM is receiving a zero return voltage. In contrast, short-circuiting the ECT connector from the PCM’s 5-volt reference terminal to the PCM’s voltage return terminal should indicate a scan tool data of approximately +300°F coolant temperature.

At the extremes, an open-circuit ECT should indicate a scan tool data of approximately -40°F coolant temperature, since the PCM is receiving a zero return voltage. In contrast, short-circuiting the ECT connector from the PCM’s 5-volt reference terminal to the PCM’s voltage return terminal should indicate a scan tool data of approximately +300°F coolant temperature.

Both temperatures are programmed into the on-board diagnostic strategy as the most extreme temperatures under which the engine might be expected to operate. The first series of “Global” circuit-related codes include P0115 (ECT circuit fault), P0117 (ECT low input voltage), P0118 (ECT high input voltage) and P0119 (ECT sensor or circuit erratic).

ELECTRICAL/MECHANICAL FAILURES

Electrical failures include low ECT return voltages caused by corroded ECT connectors or, at another extreme, a low reference voltage caused by another sensor shorting the reference voltage circuit. In some cases, a P0116 DTC will be set if the PCM detects an error in the range or performance of the ECT sensor.

Mechanical failures include low ECT return voltages caused by low coolant levels and stuck-open thermostats, which are often represented by a second series of P0125-128 DTCs. The low coolant level will cause a much lower-than-expected ECT return voltage because the ECT sensor is no longer in contact with the coolant.

Presumably, the driver will see a “low coolant” warning light on his instrument cluster. Perhaps the “Check Engine” light will be illuminated and a DTC set, or perhaps not. In contrast, the stuck-open thermostat will cause a slow warm-up time and might store a P0128 DTC simply because the PCM sees a lower-than-normal coolant temperature for a predetermined length of time.

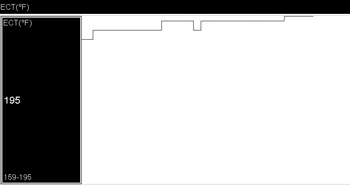

Because the ECT sensor is a primary input data, practically all ECMs and PCMs are programmed to detect open and shorted circuits in the ECT circuit. But, when detecting an out-of-range ECT sensor, the actual ECT test monitor can vary among applications. The PCM can, for example, measure the time, speed and load required to bring an engine up to a predetermined coolant temperature of, let’s say, 194°F.

If the indicated ECT data hasn’t reached the desired operating temperature during a specific time limit and at a specific engine speed and load factor, the PCM might set a P0125 (insufficient temperature for closed-loop operation) or a P0128 (coolant temperature below thermostat-regulated temperature), which in most (but not all) cases indicates a bad thermostat. If this diagnostic strategy sounds complicated, that’s because it is complicated, and also because it can vary widely among different applications.

ENABLING CRITERIA

Enabling criteria are simply the types of sensor inputs required by the PCM to run a test monitor and to set a specific DTC. Since enabling criteria are application-specific, an appropriate technical database must be consulted before making any assumptions. The engine coolant temperature is important because it forms part of the enabling criteria for many component test monitors and is part of the freeze-frame data for most DTCs.

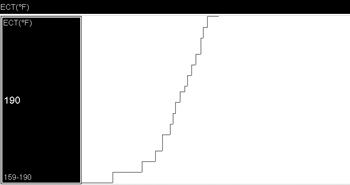

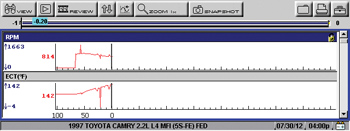

As illustrated above, if the ECT sensor is indicating a momentary dip in coolant temperature on a 1996 OBD II vehicle, the result might be a no-code, cold-engine driveability complaint because the PCM has increased fuel delivery to meet the fuel map for the indicated (not the actual) engine operating temperature. See Diagram 3.

As illustrated above, if the ECT sensor is indicating a momentary dip in coolant temperature on a 1996 OBD II vehicle, the result might be a no-code, cold-engine driveability complaint because the PCM has increased fuel delivery to meet the fuel map for the indicated (not the actual) engine operating temperature. See Diagram 3.

If the ECT is indicating a lower than actual operating temperature, it’s possible that the PCM might increase the pulse width to enrich the fuel mixture only until the oxygen sensor provides a data input to the PCM so it can assume fuel control. With early OBD II vehicles, an over-rich condition might also depend upon how much authority software engineers programmed into the PCM for the ECT input. On low-authority systems, the effects would be negligible, whereas on high-authority systems, the effects might be profound.

OLD VERSUS NEW

But let’s fast-forward to 2013 when a vehicle has a far greater capacity to detect a sensor fault than does the PCM in a 1996 model. Here’s where experience can lead us astray. For example, a 1996 engine might compare the data inputs from the IAT sensor and the ECT sensors to determine if the engine is starting from a cold-soak or a hot-soak condition. If both temperatures are within, let’s say, eight degrees of each other, the PCM assumes that the engine is starting from a cold-soak condition. This data allows the PCM to adjust the spark and fuel maps to start and run from a cold-soak condition.

But, let’s say that the ECT resistance is lower than specification and is therefore indicating a higher coolant temperature. In this case, the PCM might assume that the engine is starting from a hot-soak condition, when, in fact, it is not. This false data might cause a cold driveability complaint, and, among other things, possibly prevent the evaporative emissions monitor from running.

With 1996 vehicles, it’s also conceivable that an out-of range ECT sensor or stuck-open thermostat can prevent a DTC from being set for a defective oxygen sensor because the system never reaches closed-loop operation. Similarly, many 1996 automatic transmissions might not engage the torque converter lock-up clutch or transmission overdrive gear until the ECT sensor indicates that the engine has reached a specific operating temperature.

On the other hand, because modern heated zirconia oxygen or air/fuel ratio (AFR) sensors on a 2010 vehicle allow the PCM to assume fuel control practically as soon as the engine is started, the oxygen or AFR sensor is given more authority than the ECT sensor for entering closed-loop operation. Multiple A/F and oxygen sensors also provide a backup data stream and allow the PCM to compare the data inputs of each sensor.

So, an out-of-range ECT sensor on a 2010 vehicle would likely not affect driveability or performance as much as on a 1996 model. Instead, the 2010 PCM might project a value for the expected engine temperature by monitoring enabling criteria like intake air temperature engine speed and engine load. Furthermore, the additional computing capacity of the 2010 vehicle might allow its PCM to overlook a momentary glitch in the ECT data input (See Diagram 3 on page 28) and instead simply store an ECT-related trouble code in its diagnostic memory.

BASIC ECT DIAGNOSTICS

The simplest diagnostic strategy for diagnosing IAT and ECT sensors is to compare their data inputs after the vehicle has cold-soaked overnight. A second strategy can include using a scan tool to graph the ECT voltage. A third, but less reliable, method is to use an infrared pyrometer or “heat gun” to compare both intake air and engine cylinder head temperatures with the data stream displayed on a scan tool. But, remember that due to the “reflectivity” of various surfaces, the heat gun approach will not indicate the exact temperature indicated on the scan tool.

The simplest diagnostic strategy for diagnosing IAT and ECT sensors is to compare their data inputs after the vehicle has cold-soaked overnight. A second strategy can include using a scan tool to graph the ECT voltage. A third, but less reliable, method is to use an infrared pyrometer or “heat gun” to compare both intake air and engine cylinder head temperatures with the data stream displayed on a scan tool. But, remember that due to the “reflectivity” of various surfaces, the heat gun approach will not indicate the exact temperature indicated on the scan tool.

Lastly, make sure you’re testing the correct sensor. Keep in mind that the IAT sensor is usually integrated with the hot-wire mass air flow sensor assembly on most current vehicles. Many pre-1996 OBD I vehicles included a separate temperature sensor for activating the radiator cooling fans. Early OBD I and OBD II vehicles used a single-wire ECT sensor to supply data to the instrument cluster temperature gauge and a separate two-wire sensor to supply data to the PCM. Thanks to multiplexing, which makes it possible to share a single datastream among various control modules, modern vehicles generally use a single ECT sensor to supply engine coolant temperature data to various modules.