Measuring Radial Free-Play

Measuring Radial Free-Play Measuring Radial Free-Play

Measuring Radial Free-Play Measuring Radial Free-Play

Measuring Radial Free-PlayThe system provides great ride & handling, but it can be complicated to service if you do not have the right training.

Mercedes-Benz uses two different adjustable suspension systems in its vehicles – Airmatic and Active Body Control (ABC). Airmatic, as the name implies, is its air suspension system which we discussed back in April of this year. ABC uses hydraulic fluid at tremendous pressures to actively change the stiffness of the springs inside the shock assemblies, changing vehicle dynamics and ride height. This can be done automatically based on sensor inputs and module programming, or at the push of a button located near the shifter.

Technical Service Bulletins can be valuable in helping solve vehicle problems. But sometimes, it takes multiple TSBs to find a pattern failure or the “root cause” of a problem. In the case of the Audi/VW 2.0L Fuel Stratified Injection (FSI) engine introduced in 2006, three problems related to engine carbon and fuel issues are connected

Models: F97 X3 M F98 X4 M G01 X3 G02 X4 G20 3-Series SITUATION After replacing the microfilter during a previous service, the customer notices that the ventilation system airflow rate is noticeably less. This leads to perceived lower cooling power. The customer may also notice that external odors enter the vehicle. Related Articles –

Replacing a single coil might not be the best approach to curing an engine of a chronic misfire.

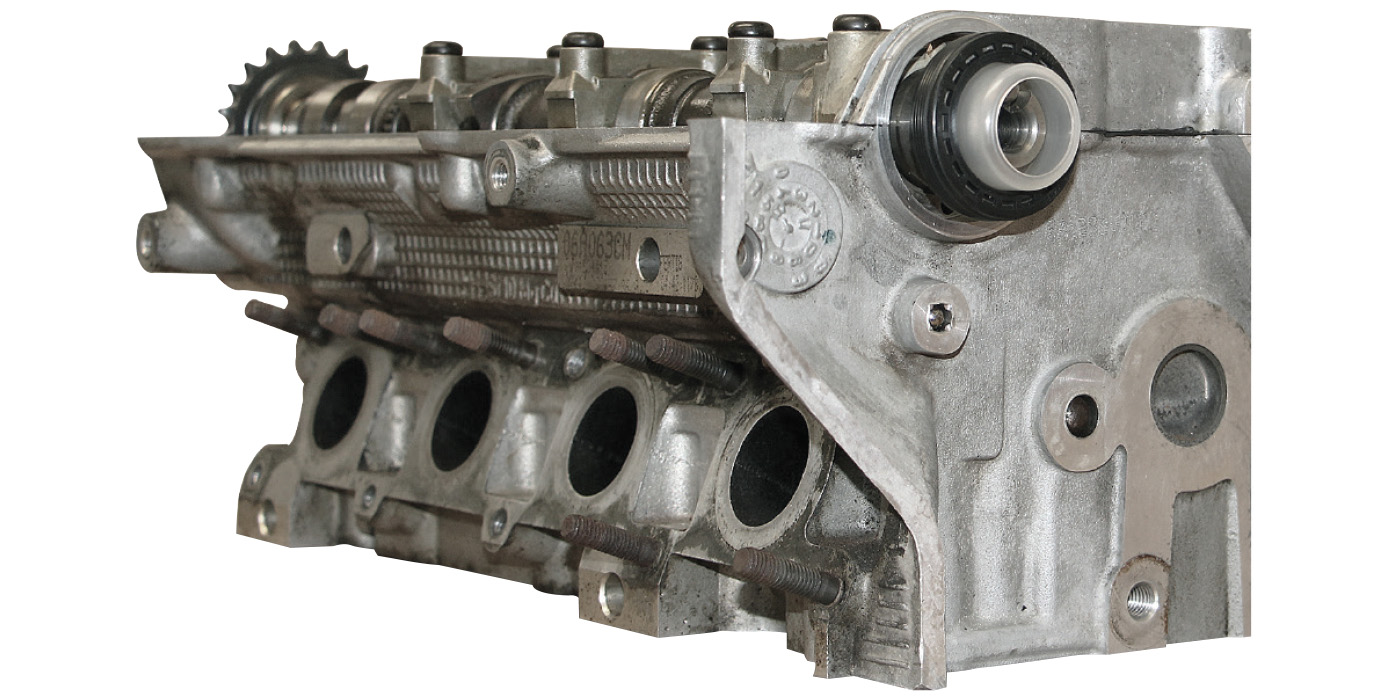

The Volvo Modular Series engine outlasted Ford and was retired by Geely. The Volvo modular design that can have four, five or six cylinders made its debut in 1990 in the 960 sedan as a six-cylinder and never stopped improving. Related Articles – How To Service BMW Tire Monitor Systems – VW DSG Maintenance –

In the 1980s, it was not uncommon for a turbocharger on some European vehicles to last only 30,000 to 40,000 miles. The failures were almost always in the center section and caused by the lack of oil to cool and lubricate the bearings and shaft. Related Articles – Air Ride Diagnostics: Reservoirs and Compressors –

The secret to diagnosing air ride problems is knowing what criteria the system uses to regulate the compressor/reservoir and having the right tool.

The 4-series does not stray far from the typical BMW engineering and operation.

The PTFE seal provides a wider operating temperature and a low coefficient of friction.